China 309L 16 Welding Rod Suppliers and Manufacturers Overview

An Overview of China’s 309L 16 Welding Rod Manufacturers

In the realm of welding materials, the 309L 16 welding rod has gained prominence due to its exceptional properties that cater to various industrial applications. Its specific formulation allows for a high level of resistance to corrosion and oxidation, making it ideal for joining dissimilar metals and for use in high-temperature applications. As a result, Chinese manufacturers have ramped up production to meet the growing global demand for 309L 16 welding rods.

Understanding 309L 16 Welding Rods

The 309L welding rod is primarily composed of stainless steel, which includes chromium, nickel, and other alloying elements. The designation 'L' signifies its low carbon content, which is crucial for preventing carbide precipitation during welding. This feature ensures the integrity of the weld joint, especially in environments where high temperatures and corrosive substances are prevalent. The ‘16’ typically refers to the rod’s diameter, indicating that it is 1.6 mm, a common size for various welding operations.

The Role of Chinese Manufacturers

China has positioned itself as a leading manufacturer of welding materials, including 309L 16 welding rods. The country boasts numerous manufacturers that specialize in producing high-quality welding consumables. These manufacturers adhere to both domestic and international standards, ensuring that their products can compete in the global market.

Quality Standards and Certifications

Many Chinese welding rod manufacturers are ISO certified, which signifies that they adhere to quality management systems that focus on customer satisfaction and product quality. Moreover, some manufacturers also obtain additional certifications such as CE and ASTM, which further enhances the credibility and acceptance of their products in international markets. These standards ensure that the welding rods are not only reliable in performance but also safe to use in various applications.

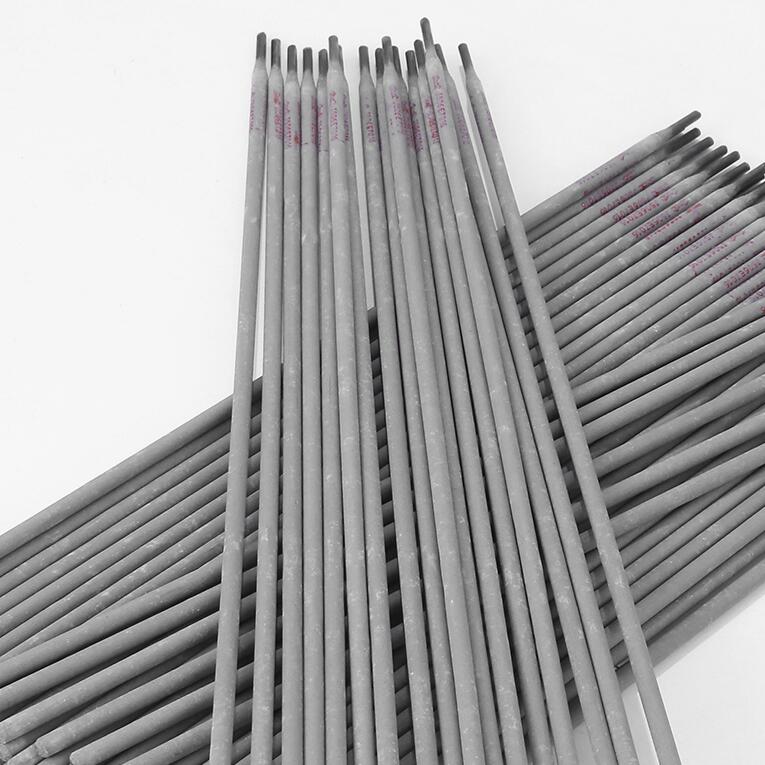

china 309l 16 welding rod manufacturers

Technological Advancements

Chinese manufacturers have invested significantly in advanced manufacturing technologies to improve product quality and efficiency. Automation, precision engineering, and stringent quality control measures are now commonplace in many production facilities. This integration of technology allows for the consistent production of high-quality 309L 16 welding rods that meet the demands of modern welding techniques.

Market Demand and Applications

The demand for 309L 16 welding rods is driven largely by industries that require high-quality welding solutions, such as construction, automotive, aerospace, and chemical processing. These rods find applications in a variety of projects, from building bridges and pipelines to fabricating high-performance machinery. The increasing globalization of these industries means that the demand for reliable and cost-effective welding solutions continues to rise, positioning Chinese manufacturers to meet this need effectively.

Competitive Pricing and Export Potential

One of the significant advantages of Chinese manufacturers is their ability to offer competitive pricing without compromising on quality. This has made them attractive to procurement divisions worldwide, as companies seek to balance quality with cost. The robust logistics networks and export capabilities facilitated by China's infrastructure also allow manufacturers to reach markets across the globe, thereby expanding their footprint in the international arena.

Conclusion

In summary, the landscape of 309L 16 welding rod manufacturing in China is vibrant and evolving. The combination of high-quality products, adherence to international standards, and competitive pricing makes Chinese manufacturers pivotal players in the global welding rod market. As industries continue to demand innovative and reliable welding solutions, these manufacturers are well-positioned to lead the charge, driving advancement and adoption of superior welding technologies. The future looks promising for both the manufacturers and the industries that rely on their products.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025