china 309 stick welding rod factory

The Landscape of China’s 309 Stick Welding Rod Factory

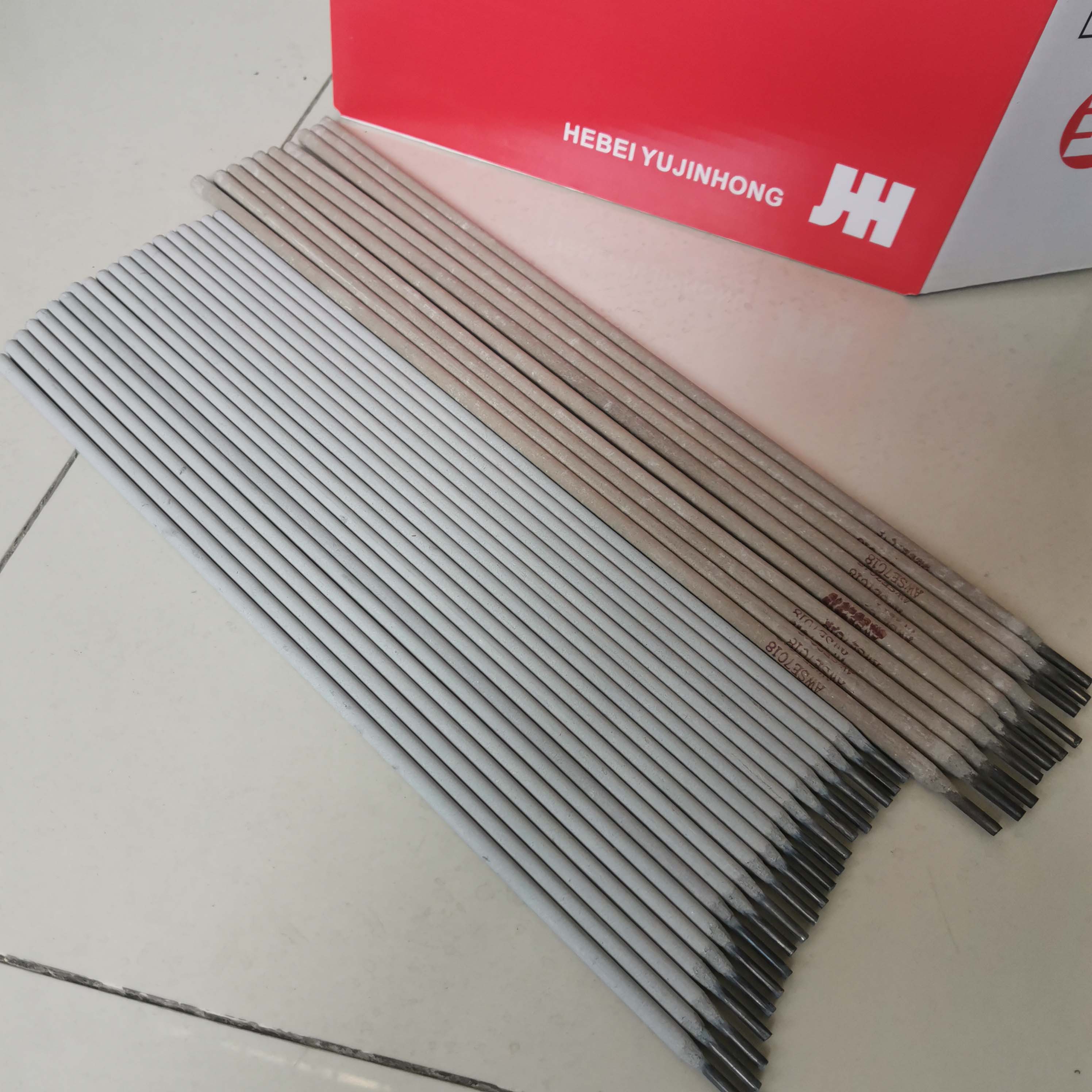

In recent years, China's industrial sector has experienced rapid advancements, making it a global leader in various manufacturing domains, including welding rod production. Among the most notable products in this sector is the 309 stick welding rod, which is integral to various welding applications due to its exceptional properties. This article delves into the significance of 309 stick welding rods and provides an overview of the factories engaged in their production in China.

Understanding 309 Stick Welding Rods

309 stick welding rods are primarily used for welding dissimilar metals and alloys, especially stainless steel. Composed of a nickel-chromium alloy, these rods are known for their high strength, resistance to oxidation, and excellent corrosion resistance. The rods can be applied in environments where thermal and mechanical stress are considerable, making them essential in industries such as construction, manufacturing, and shipbuilding.

The versatility of the 309 rods allows them to be used for a variety of welding processes, including shielded metal arc welding (SMAW), also known as stick welding. This method is particularly favored for its portability and simplicity, making 309 stick rods a popular choice among welders.

Overview of Manufacturing in China

China houses numerous factories specialized in the production of welding rods, including the widely popular 309 stick welding rods

. These factories leverage advanced technologies and practices to ensure that their products meet international standards in terms of quality and performance.The manufacturing process involves several key stages raw material selection, alloying, forming, and quality testing. Factories source high-quality steels and alloys, which are then meticulously processed in controlled environments to maintain the required chemical composition. The rods are extruded to precise dimensions and undergo rigorous testing to ensure optimal performance and durability.

Innovation and Standards

china 309 stick welding rod factory

To maintain a competitive edge and adapt to the fast-paced industrial landscape, many Chinese welding rod manufacturers are investing in research and development. Innovations such as improved alloy compositions, enhanced coating techniques, and automated production lines are becoming commonplace.

Moreover, adherence to international standards is crucial for these factories. Many are certified by recognized organizations, ensuring that their products comply with standards such as ISO and AWS. This commitment to quality not only boosts consumer confidence but also opens doors to international markets.

Environmental Considerations

As environmental concerns grow globally, Chinese factories are adopting sustainable practices in their manufacturing operations. This includes waste recycling initiatives, energy-efficient production techniques, and reduction of harmful emissions. By incorporating these sustainable practices, manufacturers can minimize their environmental footprint while maintaining production efficiency.

Economic Impact

The production of 309 stick welding rods significantly contributes to the Chinese economy. It not only provides numerous jobs across manufacturing plants but also supports ancillary industries such as raw material suppliers and logistics providers. As global demand for high-quality welding rods rises, Chinese factories are ideally positioned to meet this demand, potentially increasing export revenues and reinforcing the country’s manufacturing dominance.

Conclusion

The 309 stick welding rod factories in China symbolize the nation’s robust industrial backbone, reflecting a blend of traditional craftsmanship and modern technology. As the world continues to evolve, the demand for high-quality welding materials will only intensify, and China’s factories are ready to rise to the occasion, driving innovation and sustainability in the welding industry. With their commitment to quality, adherence to international standards, and focus on environmental responsibility, these factories are contributing significantly to both the local and global economies, ensuring that they remain a key player in the manufacturing landscape for years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025