china 7016 welding rod factory

The Rise of China’s 7016 Welding Rod Factory

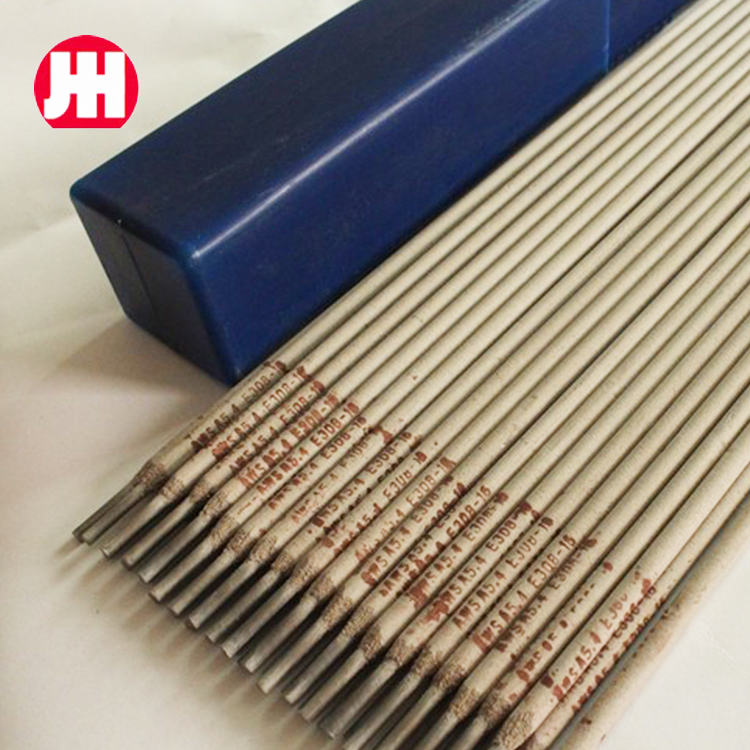

In recent years, China has established itself as a global leader in manufacturing, and one of the standout sectors is its welding rod production. Among the various types of welding rods, the 7016 welding rod has garnered significant attention for its outstanding performance in various industrial applications. The 7016 welding rod is primarily used for welding high-strength steels and is known for its excellent mechanical properties, including high tensile strength and resistance to impact and fatigue. This article explores the significance, production processes, and future prospects of China’s 7016 welding rod factory industry.

Significance of 7016 Welding Rods

The 7016 welding rod, classified under the AWS classification system, is designed for specific applications requiring enhanced strength and durability. Its primary application lies in the construction of bridges, buildings, and other structures that demand robust welding solutions. The ability to seamlessly join high-strength steels makes the 7016 welding rod a preferred choice for professionals in heavy manufacturing and construction industries. Additionally, its remarkable weldability and minimal deformation during the welding process contribute to its increasing popularity.

As industrial projects become more demanding, the need for reliable welding materials with superior qualities is paramount. The 7016 welding rod not only meets these expectations but also augments safety and longevity, making these rods indispensable for modern constructions. Consequently, the factories that produce these welding rods have become crucial players in the industrial supply chain, supporting numerous sectors worldwide.

The Production Process

The production of 7016 welding rods entails a series of intricate processes that ensure the final product meets the stringent quality standards. The manufacturing begins with the selection of high-quality raw materials, typically consisting of alloying elements such as manganese and iron. These materials are melted and blended before being extruded into the desired rod shape.

china 7016 welding rod factory

Once the rods are formed, they undergo a thorough inspection to assess their mechanical properties and chemical composition. This quality control phase is essential to ensure the rods' reliability when utilized in demanding industrial environments. After passing the inspection, the rods are coated with a flux compound that enhances their performance during welding. The coating promotes smoother arc stability and minimizes spatter, ensuring clean and strong welds.

The factories employ advanced machinery and technology to streamline production and optimize efficiency. Automation plays a critical role in the manufacturing process, reducing labor costs and minimizing errors. Moreover, strict adherence to international standards, such as ISO certifications, ensures that the products are compatible with global market requirements.

Future Prospects

Looking ahead, the future of China’s 7016 welding rod factory industry appears promising. As the demand for advanced materials continues to rise, driven by infrastructure development and industrialization, the production capacity of these factories is likely to expand. Innovations in welding technology, such as improvements in alloy compositions and coating techniques, will enhance the quality and application of 7016 welding rods.

Furthermore, as industries pivot towards sustainable practices, Chinese manufacturers are expected to invest in eco-friendly production methods. This shift will not only cater to the growing market but will also fulfill corporate social responsibility commitments.

In conclusion, China’s 7016 welding rod factories stand at the forefront of the welding industry, combining advanced technology with a commitment to quality. With a robust foundation and an eye on future innovations, these factories are poised to play a pivotal role in the global manufacturing landscape, ensuring that the demands of modern construction and fabrication are met with precision and excellence. As the industry evolves, the reputation of Chinese welding products, particularly the 7016 welding rod, will undoubtedly continue to flourish on the world stage.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025