china 7018 arc welding rod factories

The Landscape of China’s 7018 Arc Welding Rod Factories

Arc welding is a vital process in various industries, including construction, automotive, and manufacturing. Among the numerous welding electrodes available, the 7018 arc welding rod is particularly favored for its excellent mechanical properties and versatility. In recent years, China has emerged as a key player in the global production of 7018 arc welding rods, establishing numerous factories that specialize in manufacturing these essential components. This article delves into the factors contributing to China's dominance in this sector, the quality of the products, and the future of 7018 arc welding rod manufacturing.

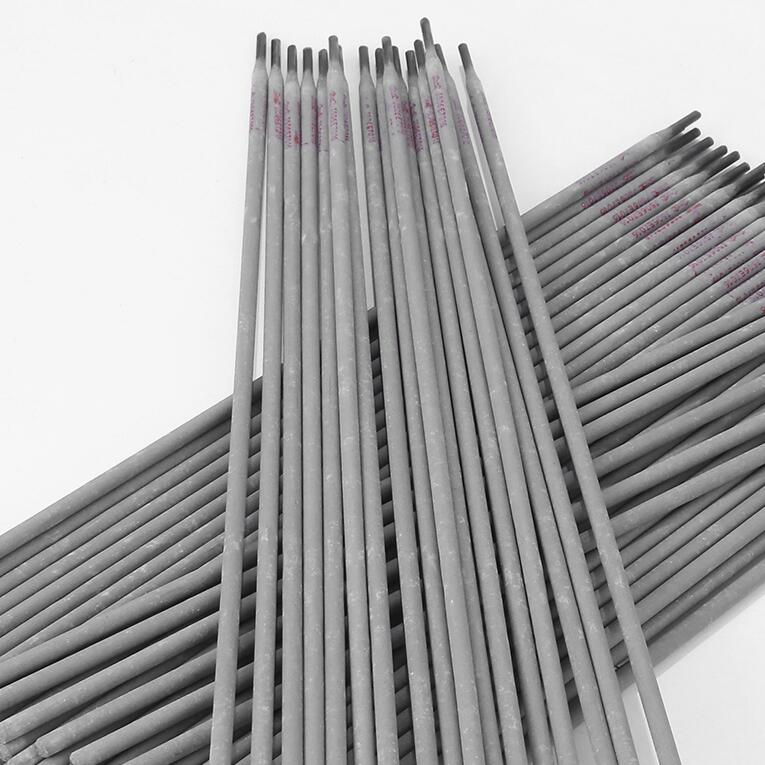

Understanding 7018 Arc Welding Rods

The 7018 arc welding rod is a low-hydrogen electrode that provides excellent weld quality and is often used for structural welding. Characterized by its high tensile strength and ductility, the 7018 rod is suitable for welding carbon and low-alloy steels, making it a staple in industries requiring reliable joints. The designation 7018 refers to the material's tensile strength (70,000 psi), position of welding (1 representing flat and horizontal), and the type of coating (8 indicates it is low-hydrogen).

Growing Demand for Welding Rods

In the context of rapid industrialization and infrastructure development, particularly in developing nations, the demand for high-quality welding rods has surged. China, with its robust manufacturing capabilities, has become a prominent supplier in this domain. The country’s factories, equipped with state-of-the-art technology, can produce large quantities of 7018 rods that meet international standards. This capacity not only fulfills domestic needs but also caters to export markets, making China a significant player in the global welding rod industry.

Quality Assurance and Standards

Chinese manufacturers of 7018 arc welding rods have made substantial investments in technology and quality control measures. Many factories adhere to international standards such as ISO 9001, ensuring that their products meet stringent quality benchmarks. The use of advanced machinery and automated processes helps minimize defects and improve overall product consistency. Additionally, companies often engage in rigorous testing procedures, including tensile strength tests and weld integrity assessments, to guarantee that their rods perform reliably in various applications.

china 7018 arc welding rod factories

Environmental Considerations

As the global market for welding rods expands, so do the environmental considerations associated with production. Many Chinese factories are increasingly adopting sustainable practices, such as reducing waste and energy consumption during manufacturing. The incorporation of eco-friendly materials and processes aligns with international trends aimed at reducing carbon footprints and promoting sustainable development. This shift not only helps meet regulatory requirements but also enhances the appeal of Chinese-produced welding rods in eco-conscious markets.

Challenges and Competitiveness

While China's 7018 arc welding rod factories are well-positioned in the global market, they do face challenges. Intense competition from manufacturers in countries like the United States, Japan, and South Korea poses a threat to China's market share. Additionally, fluctuations in raw material prices and ongoing trade tensions can affect production costs and profitability. To maintain a competitive edge, Chinese manufacturers are focusing on innovative techniques, product diversification, and improved customer service.

The Future of 7018 Arc Welding Rod Manufacturing in China

Looking ahead, the future of 7018 arc welding rod manufacturing in China appears promising. The ongoing investments in technology, quality, and sustainability are likely to bolster the reputation of Chinese welding products on the global stage. As industries evolve, the demand for specialized and high-performance welding rods will continue to grow, providing further opportunities for Chinese manufacturers to expand their reach.

In conclusion, China’s 7018 arc welding rod factories play a crucial role in the global welding industry, driven by quality, capacity, and innovation. As these factories navigate challenges and embrace sustainable practices, they will continue to be pivotal in meeting the world’s welding needs, solidifying China’s position as a leader in the production of high-quality welding electrodes.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025