china 7018 welding electrode factories

The Landscape of Welding Electrode Factories in China

In recent years, China has established itself as a global manufacturing powerhouse, with a significant emphasis on the production of welding electrodes. These critical components are essential in various industrial applications, including construction, shipbuilding, automotive, and aerospace industries. The country is home to numerous welding electrode factories, each contributing to the robust supply chain and innovation in welding technologies.

Overview of the Welding Electrode Industry in China

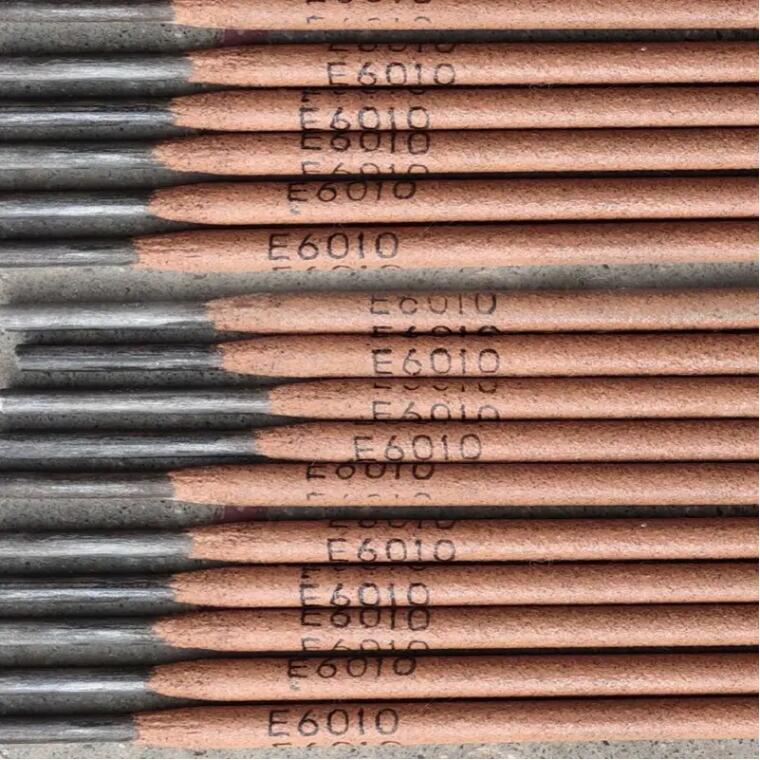

Welding electrodes serve as the consumable material used in welding processes to create a bond between metal parts. The manufacturing of these electrodes involves careful selection of raw materials, including metallic and non-metallic components, which are crucial for ensuring the quality and performance of the welds. In China, factories producing welding electrodes employ advanced techniques and machinery to meet the increasing demand both domestically and internationally.

China's welding electrode industry has seen tremendous growth due to several factors. The rapid urbanization, infrastructural development, and proliferation of manufacturing activities have significantly boosted the demand for welding electrodes. Furthermore, the government's initiatives aimed at promoting industrial growth have spurred investments in this sector, leading to increased production capacity and technological advancements.

Key Players in the Chinese Market

China's welding electrode market is characterized by a mix of large-scale manufacturers and smaller enterprises. Prominent companies such as Beijing Jingcheng Machinery Electric Company, Hunan Valin Steel Pipe Co., and Jiangsu Yongyi Welding Materials Co. are among the leaders in this industry. These companies utilize modern production methods and quality control processes to ensure their products meet international standards.

Moreover, many factories in China are shifting towards more environmentally friendly production practices. The introduction of more sustainable materials and processes reflects the growing global emphasis on environmental responsibility. Additionally, research and development efforts are being directed towards improving the effectiveness and durability of welding electrodes, thereby enhancing their performance in various applications.

china 7018 welding electrode factories

Export and Global Impact

China is one of the world's largest exporters of welding electrodes, supplying significant amounts to markets in North America, Europe, Africa, and Asia. The competitive pricing of Chinese products, driven by economies of scale and efficient production processes, allows these electrodes to gain considerable market share internationally. This has enabled China not only to foster economic growth within its borders but also to influence global welding practices.

Welding electrodes produced in China are recognized for their quality and versatility. Manufacturers are increasingly focusing on producing specialized electrodes that cater to specific applications, such as stainless steel welding, cast iron welding, and other specialized materials. This tailored approach enhances the competitiveness of Chinese welding electrodes on the global stage.

Challenges and Future Prospects

Despite the success of the welding electrode factories in China, the industry faces several challenges. Environmental regulations are becoming stricter, requiring manufacturers to invest in cleaner technologies and processes. Additionally, fluctuations in raw material prices can impact production costs and profitability.

Looking toward the future, the welding electrode industry in China is poised for continued growth. The ongoing advancements in technology, along with the increasing demand for high-quality welding products, present ample opportunities for manufacturers. Furthermore, as global infrastructure projects ramp up in response to post-pandemic recovery initiatives, the need for reliable welding solutions is expected to surge.

Conclusion

The welding electrode factories in China play a pivotal role in the global supply chain, adapting to the changing dynamics of the manufacturing landscape. With a focus on quality, innovation, and sustainability, these factories are not only meeting domestic demands but are also contributing significantly to international markets. As the industry evolves, it will continue to navigate challenges while pursuing opportunities that arise from an ever-expanding global economy.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025