Top Manufacturers of Aluminum 4043 Welding Rods in China and Their Key Features

The Growing Market for China’s Aluminum 4043 Welding Rod Manufacturers

The demand for high-quality welding materials has seen a significant uptick in recent years, especially with the increased use of aluminum in various industries. Among the many products available in the market, the Aluminum 4043 welding rod has emerged as a popular choice for welding applications, particularly in the automotive, aerospace, and construction sectors. China has positioned itself as a leading manufacturer of Aluminum 4043 welding rods, catering to both domestic and international markets.

Understanding Aluminum 4043 Welding Rods

Aluminum 4043 is an aluminum-silicon alloy that is commonly used for welding due to its excellent fluidity and low shrinkage rate. It is particularly favorable for welding aluminum to aluminum and aluminum to magnesium, making it a versatile option for many applications. The alloy's composition, which typically contains about 4.5% silicon, ensures a smooth finish and reduces the risks of cracking and distortion during the welding process. These properties make Aluminum 4043 welding rods suitable for a range of welding techniques, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding.

China’s Role in the Global Market

China has become a significant player in the aluminum welding rod manufacturing sector, primarily due to its advanced production techniques, extensive raw material resources, and competitive pricing. Chinese manufacturers have invested heavily in modern manufacturing processes and technologies, thus ensuring that their products meet international quality standards. This commitment to quality has garnered trust from customers worldwide, making Chinese Aluminum 4043 welding rods highly sought after.

The manufacturing landscape in China features a combination of established companies and emerging enterprises, all vying for a share of the growing global market. Many of these manufacturers export their products to countries in Europe, North America, and Southeast Asia, indicating their strong foothold in international trade.

Advantages of Sourcing from China

1. Cost-Effectiveness One of the primary advantages of sourcing Aluminum 4043 welding rods from China is the cost-effectiveness. Competitive labor costs and economies of scale allow Chinese manufacturers to offer high-quality rods at lower prices than their counterparts in other countries.

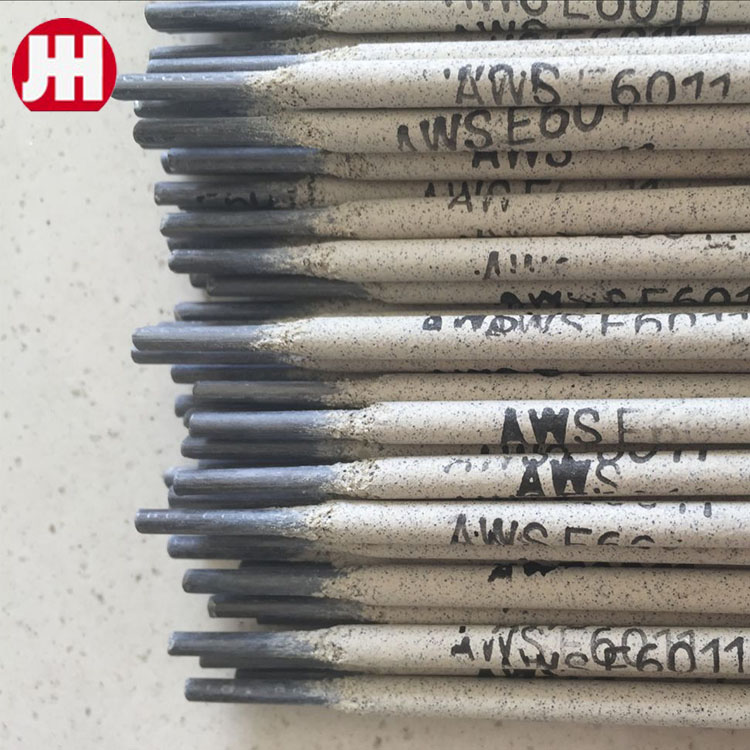

china aluminum 4043 welding rod manufacturers

2. Quality Assurance Many Chinese manufacturers adhere to strict quality control measures, ensuring that their products consistently meet international standards. This dedication to quality has led to a favorable reputation, making it easier for global clients to trust their products.

3. Variety of Options Chinese manufacturers often provide a wide range of aluminum welding products, including different alloys and sizes of welding rods. This allows customers to find products that perfectly suit their specific requirements.

4. Efficient Supply Chain China’s well-established supply chains facilitate smooth logistics and timely deliveries. Many manufacturers have forged strong partnerships with logistics providers, ensuring that orders are fulfilled promptly and efficiently.

Challenges Faced by Manufacturers

Despite the advantages, Chinese Aluminum 4043 welding rod manufacturers also face several challenges. The primary concern is the fluctuating prices of raw materials, which can affect production costs and profit margins. Additionally, the industry must navigate stringent regulations regarding quality and safety, especially when exporting to countries with rigid standards.

Moreover, increasing competition from other countries producing aluminum welding rods has put pressure on Chinese manufacturers to maintain their competitive edge by innovating and improving their product offerings.

The Future of Aluminum 4043 Welding Rods in China

Looking ahead, the demand for Aluminum 4043 welding rods is expected to continue growing as industries increasingly favor lightweight materials like aluminum for their projects. As a result, Chinese manufacturers that adapt to changing technological trends and consumer demands are well-positioned to thrive.

In conclusion, China stands out as a pivotal hub for Aluminum 4043 welding rod manufacturing, driven by its cost-effectiveness, commitment to quality, and extensive product variety. Although challenges exist, the future looks promising as manufacturers continue to innovate and meet the evolving needs of global markets. The collaboration and exchange between Chinese manufacturers and international buyers are likely to foster further growth in this dynamic sector.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025