china aluminum flux core wire manufacturers

The Rise of Chinese Aluminum Flux Core Wire Manufacturers

In recent years, the manufacturing sector in China has witnessed significant advancements, particularly in the field of welding and fabrication materials. Among these developments, aluminum flux core wires have gained considerable attention for their efficient performance and versatility in various applications, including automotive, aerospace, and construction industries. This article explores the landscape of aluminum flux core wire manufacturers in China and their impact on global markets.

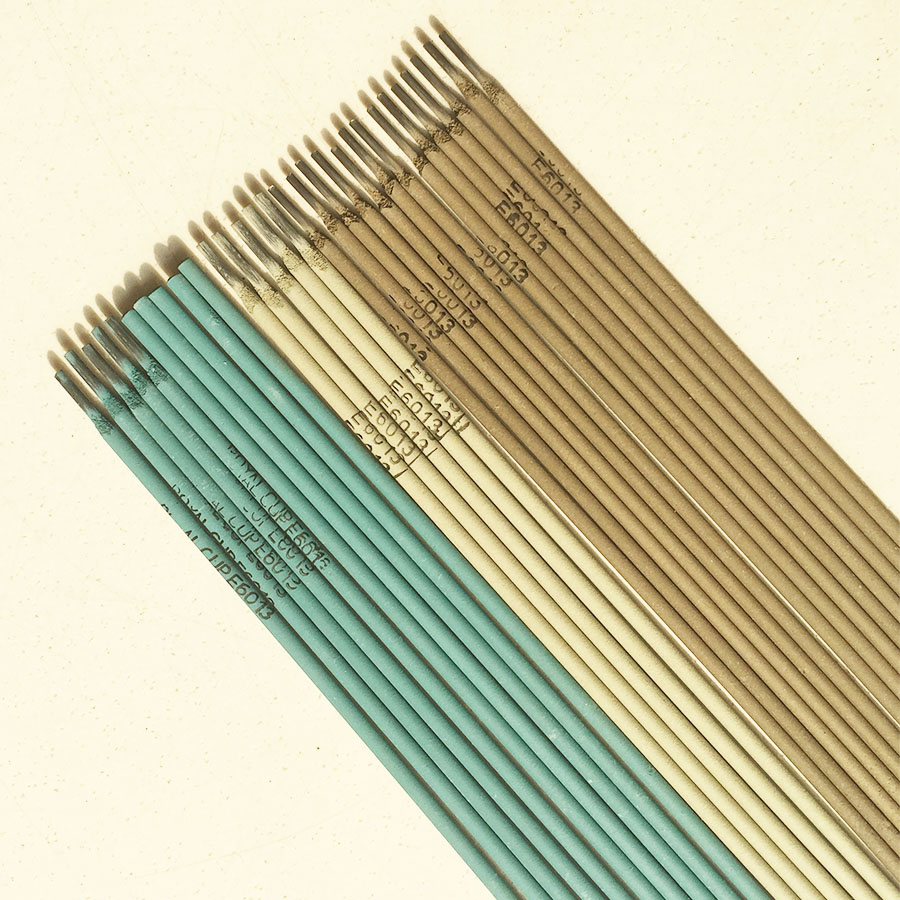

Aluminum flux core wires are essential materials used in the welding process, particularly for joining aluminum and its alloys. Unlike traditional solid wires, flux core wires contain a core filled with flux material that aids in producing high-quality welds by providing shielding against contamination. This innovative design helps to create cleaner, stronger welds and can be particularly beneficial in outdoor welding operations where environmental conditions may impair the quality of the weld.

China is home to a growing number of manufacturers that specialize in the production of aluminum flux core wires. These manufacturers have invested heavily in advanced production technologies, resulting in higher quality products that meet international standards. They employ industrial-grade machinery and adhere to rigorous quality control protocols, which ensures that their products are reliable and efficient for various welding applications.

china aluminum flux core wire manufacturers

One key advantage of sourcing aluminum flux core wires from Chinese manufacturers is cost-effectiveness. The competitive manufacturing environment in China allows companies to offer their products at lower prices compared to counterparts in other regions, making it an attractive option for businesses looking to optimize their welding operations without compromising on quality. Additionally, many manufacturers provide customizable solutions, enabling customers to specify particular characteristics such as diameter, flux composition, and spool size, tailored to meet specific needs.

Moreover, the increasing focus on sustainability and eco-friendly practices has pushed many Chinese manufacturers to develop green alternatives in their production processes. This trend resonates well with global companies prioritizing environmentally responsible materials, further enhancing the appeal of Chinese aluminum flux core wires in the international market.

As the demand for high-quality welding materials continues to grow worldwide, Chinese aluminum flux core wire manufacturers are well-positioned to play a pivotal role in fulfilling this need. With ongoing investments in technology and production efficiency, they are set to enhance their reputation as reliable suppliers, thus solidifying China’s position as a key player in the global welding industry.

In conclusion, the rise of aluminum flux core wire manufacturers in China marks a significant development in the materials production sector. With their commitment to quality, cost efficiency, and innovation, these manufacturers not only cater to domestic needs but also serve the growing global market, making a substantial impact on the future of welding technologies.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025