Top Quality Flux Core Welding Wire from Leading Chinese Manufacturer

The Best Flux Core Welding Wire from China A Comprehensive Overview

Welding is an essential process in various industries, and the choice of welding wire significantly impacts the quality of the welded joint. Among the different types of welding wires available, flux-cored welding wire has garnered considerable attention due to its efficiency and versatility. In China, factories specializing in the production of high-quality flux core welding wire have emerged as leaders in the global market. This article delves into the key features of the best flux core welding wire produced by Chinese manufacturers, the advantages of using this type of wire, and why China is a preferred source for welders around the world.

1. Understanding Flux-Cored Welding Wire

Flux-cored welding wire is characterized by a hollow structure filled with flux, which provides a protective covering during the welding process. This type of wire can be used for both gas shielded and self-shielded applications, making it suitable for various welding conditions.

The main components of the wire include a metal outer sheath and a core filled with flux material, which protects the weld pool from contamination by atmospheric gases, and provides additional alloying elements to enhance the properties of the weld.

2. Features of the Best Chinese Flux Core Welding Wire

Chinese factories produce a range of flux core welding wires that stand out in terms of quality and performance. Here are some key features that distinguish the best products

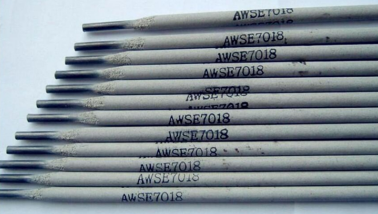

- Consistent Quality Renowned manufacturers implement stringent quality control measures throughout the production process, ensuring that each batch of wire meets international standards such as AWS (American Welding Society) specifications.

- Wide Variety of Options Chinese factories offer a diverse selection of flux core welding wires, suitable for different applications such as carbon steel, stainless steel, and even hard-facing materials.

- Excellent Weldability The best flux core wires provide smooth arc stability, minimal spatter, and good penetration, resulting in strong and aesthetic welds.

- Customization Many factories in China enable customers to customize their flux core welding wire according to specific requirements, such as diameter, flux composition, and packaging

.3. Advantages of Using Flux Core Welding Wire

Flux core welding wire comes with numerous benefits that make it a preferred choice among welders

china best flux core welding wire factory

- High Efficiency Flux-cored welding is known for its high deposition rates, which translates to faster welding processes and increased productivity.

- Versatility This type of wire can be used in various positions (flat, horizontal, vertical, and overhead), making it ideal for a wide range of applications, including construction, shipbuilding, and repair work.

- Less Sensitivity to Wind Self-shielded flux core welding wires can be used outdoors with minimal concern about wind affecting the shielding gas, making them suitable for open-air welding applications.

- Cost-Effective Flux core welding wires are generally more affordable than other types of welding wires, providing an economical solution without compromising quality.

4. Why Choose Chinese Manufacturers?

There are several reasons why welders and companies around the world opt for flux core welding wire produced in China

- Competitive Pricing Chinese manufacturers are known for their cost-effective production processes, which allow them to offer high-quality wires at competitive prices.

- Innovative Technology Many leading factories in China invest significantly in research and development, incorporating advanced technology and manufacturing techniques to enhance the quality and performance of their products.

- Global Supply Chains Chinese factories often have well-established supply chains, ensuring timely delivery to customers worldwide, which is crucial for projects with tight deadlines.

- Growing Industry Reputation With a focus on quality and customer satisfaction, many Chinese manufacturers are increasingly gaining recognition and respect in the international welding community.

Conclusion

Choosing the right flux core welding wire is crucial for achieving high-quality welds in various applications. With the vast options available from Chinese factories, welders can find products that not only meet their needs but also exceed their expectations in performance and value. As the demand for quality welding materials continues to rise globally, China's contribution to the flux core welding wire market is poised to play a significant role in shaping the future of welding technology.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025