China Cast Iron MIG Welding Wire for High-Quality Metal Fabrication and Repairs

Understanding China Cast Iron MIG Wire An Insight into Production and Applications

MIG (Metal Inert Gas) welding is a popular welding process that utilizes a continuous wire feed to create a strong bond between metals. In recent years, the demand for quality MIG wire has surged, particularly in countries like China, which has become a significant player in the global manufacturing landscape. Among the various types of MIG wires, cast iron MIG wire has gained particular attention due to its unique properties and applications.

What is Cast Iron MIG Wire?

Cast iron MIG wire is specifically designed for welding ferrous metals, primarily cast iron components. This type of wire is essential for industries that deal with casting processes, particularly in sectors like automotive, machinery, and construction. Cast iron itself is known for its hardness, brittleness, and excellent castability. However, welding cast iron can be challenging due to its high carbon content and low ductility. As a result, the development of specialized MIG wire is crucial for ensuring quality welds and structural integrity.

Characteristics of China Cast Iron MIG Wire

Cast iron MIG wire produced in China is typically composed of various alloying elements, which are essential for enhancing the performance of the wire. These elements include nickel, manganese, and silicon, which help increase the fusion properties and improve the overall quality of the welds. One of the distinguishing features of this wire is its ability to withstand high temperatures and resist cracking, making it suitable for high-stress applications.

Additionally, the wire is designed to provide an excellent arc stability, allowing for smoother operation during the welding process. The consistency of the wire feed is another critical aspect that ensures a uniform weld bead, thereby enhancing the final product's aesthetics and mechanical properties.

The Manufacturing Process

China's advanced manufacturing capabilities play a vital role in producing high-quality cast iron MIG wire. The production begins with the selection of raw materials, followed by precise alloying to achieve the desired chemical composition. After the mixture is prepared, the wire undergoes a drawing process to reach the desired diameter, usually between 0.8 mm to 1.6 mm.

china cast iron mig wire

Once drawn, the wire is subjected to a series of tests, including tensile strength and chemical composition analyses, to ensure compliance with international standards. The finished product is then packaged for distribution, highlighting China's commitment to quality control and consistency.

Applications of Cast Iron MIG Wire

The applications for cast iron MIG wire are vast. In the automotive industry, the wire is commonly used for repairing engine blocks, manifolds, and other critical components. The ability to create reliable joints that can endure the stresses and strains of operating environments makes this wire indispensable for mechanics and machinists alike.

In construction, cast iron MIG wire finds its place in the fabrication of structural components and reinforcement of cast iron pipes and fittings. Its durability and resistance to wear make it an ideal choice for projects that require long-lasting materials.

Moreover, the wire is used in repair and maintenance operations, particularly in heavy machinery where cast iron parts are prevalent. By employing high-quality MIG wire, technicians can restore and reinforce components, thereby extending the life of costly equipment.

Conclusion

As the demand for quality welding materials continues to rise, China's cast iron MIG wire stands out as a reliable option for various industries. Its unique properties, coupled with advanced manufacturing processes, ensure that welders can achieve optimal results while working with cast iron. By understanding the significance of this material, companies can make informed decisions about their welding needs, ultimately leading to better quality products and enhanced productivity.

As we move forward, the potential for innovation in cast iron MIG wire will likely continue, with advancements in technology paving the way for even better performance and reliability. This is a key factor for businesses looking to thrive in competitive markets, making quality cast iron MIG wire an essential component of successful welding projects. Whether in automotive repair shops or construction sites, the importance of this specialized product cannot be understated.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

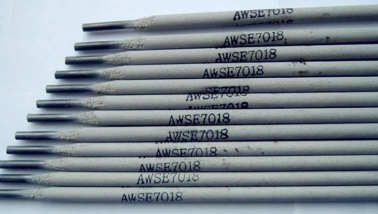

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025