CO2 MIG MAG Welding Wire Manufacturers in China for Quality Welding Solutions

China CO2 MIG MAG Welding Wire Manufacturer Shaping the Future of Welding

In the modern industrial landscape, welding plays a crucial role in manufacturing processes, particularly in sectors such as construction, automotive, and aerospace. Among the various welding techniques, CO2 MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding stand out for their efficiency and versatility. As demand for high-quality welding solutions continues to rise globally, China has emerged as a leading manufacturer of CO2 MIG MAG welding wires, significantly impacting the welding industry.

Overview of CO2 MIG MAG Welding

MIG welding utilizes a continuous wire feed that melts to create a strong bond between metals. The addition of CO2 as a shielding gas enhances the welding process by protecting the molten metal from atmospheric contamination. MIG welding is widely favored for its speed and ease of use, making it an ideal choice for automated welding applications. In contrast, MAG welding employs active gases, such as argon and oxygen mixtures, which can enhance the properties of the weld, especially in applications that involve different metal types.

The Role of China in the Welding Wire Market

China has solidified its position as a powerhouse in the global welding wire market, contributing significantly to the production of CO2 MIG MAG welding wires. The rise of advanced manufacturing technologies and increased investments in research and development have enabled Chinese manufacturers to produce high-quality welding wires that meet international standards. This growth is driven by several factors, including

1. Cost-Effectiveness Chinese manufacturers benefit from lower labor costs and abundant raw materials, allowing them to produce welding wires at competitive prices. This affordability makes it easier for companies worldwide to access quality welding solutions without straining their budgets.

2. Advanced Technology Continuous investments in technology and machinery have empowered Chinese manufacturers to produce welding wires with superior characteristics, such as improved tensile strength, flexibility, and corrosion resistance. This advancement ensures that their products meet the growing demands of diverse industries.

3. Research and Development Many Chinese welding wire manufacturers collaborate with universities and research institutions to innovate and enhance their product lines. This focus on R&D leads to improved formulations and products tailored to specific applications and customer needs.

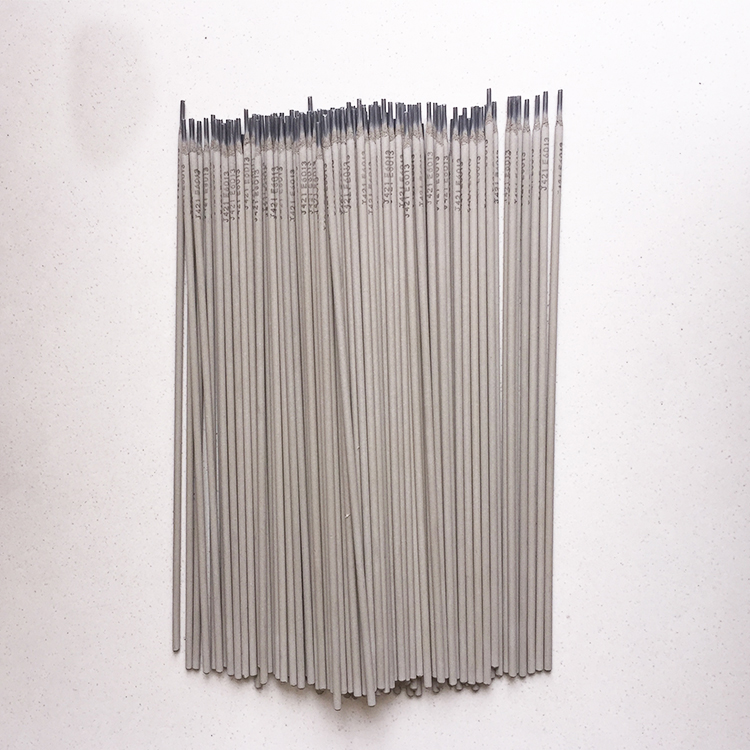

china co2 mig mag welding wire manufacturer

Quality and Standards

To maintain their competitiveness, Chinese manufacturers of CO2 MIG MAG welding wires uphold strict quality control measures. Most manufacturers adhere to international quality standards such as ISO 9001, ensuring that their products are reliable and durable. Rigorous testing and certification processes help guarantee that the welding wires can withstand different welding environments and techniques.

Moreover, many manufacturers customize their welding wires to cater to the specific needs of various industries. For instance, automotive manufacturers may require welding wires that provide visual appeal and structural integrity, while construction projects may demand superior strength and resistance to environmental factors. This adaptability is one of the key advantages of sourcing welding wires from China.

Global Collaboration and Export

As the demand for quality welding solutions increases across the globe, many countries are turning to China for their welding wire needs. The country’s extensive supply chain and logistical networks facilitate efficient export processes, allowing overseas clients to receive their orders quickly and reliably. Manufacturers often participate in international trade shows and exhibitions to showcase their products, strengthening their presence in global markets.

Furthermore, Chinese manufacturers are increasingly committed to sustainability practices, focusing on environmentally friendly products and production methods. This shift aligns with worldwide trends toward greener manufacturing and positions Chinese companies as responsible partners in the welding industry.

Conclusion

As industries continue to evolve, the demand for dependable welding solutions will only grow. China’s role as a leading manufacturer of CO2 MIG MAG welding wires is pivotal in fulfilling this demand through innovation, quality assurance, and cost-effective solutions. Through collaboration and a commitment to excellence, Chinese manufacturers are not only shaping the future of welding but also establishing lasting relationships with clients around the world. As businesses seek reliable partners to support their manufacturing processes, the impact and influence of Chinese welding wire manufacturers are set to flourish in the years to come.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025