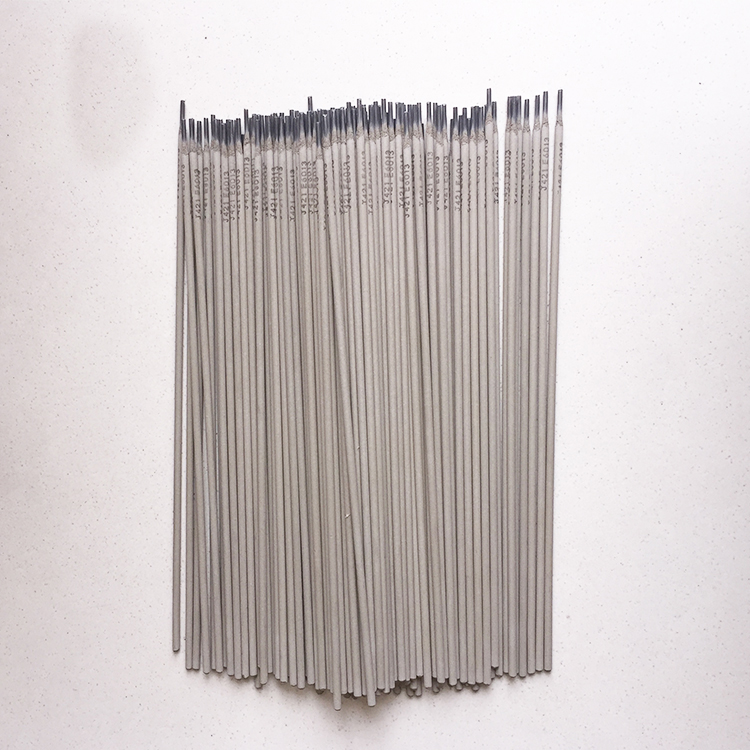

china copper welding wire 2mm manufacturer

Understanding 2mm Copper Welding Wire A Focus on Chinese Manufacturers

Welding is an essential process in numerous industries, from automotive manufacturing to construction, and the quality of welding materials plays a significant role in determining the strength and durability of the resulting structures. One of the critical components in welding is the choice of welding wire, particularly copper welding wire. Among the various options available, 2mm copper welding wire is popular due to its versatility and effectiveness. This article explores the significance of 2mm copper welding wire and highlights the role of Chinese manufacturers in this market.

The Importance of Copper Welding Wire

Copper welding wire is known for its excellent conductivity and high corrosion resistance, making it an ideal choice for various welding applications. The 2mm diameter is particularly favored because it strikes a balance between ease of handling and the ability to produce strong welds. This size is commonly used in MIG (Metal Inert Gas) welding, which is widely employed in both industrial and DIY projects. Copper welding wire is suitable for welding metals such as copper, brass, and other non-ferrous materials, which are often used in electrical and plumbing installations.

One of the main advantages of using 2mm copper welding wire is its ability to achieve high-quality welds with minimal spatter. This reduces the amount of cleanup required after welding, saving time and improving efficiency. Additionally, copper welding wire offers excellent heat distribution, reducing the risk of warping and ensuring a more stable weld.

Chinese Manufacturers Leaders in Copper Welding Wire Production

China has emerged as a leading manufacturer of welding materials, including copper welding wire. The country boasts a vast array of companies that specialize in the production of welding wires, including 2mm copper welding wire. These manufacturers leverage advanced technology and processes to ensure that their products meet international standards for quality and performance.

china copper welding wire 2mm manufacturer

One of the significant advantages of sourcing 2mm copper welding wire from Chinese manufacturers is the cost-effectiveness. Chinese companies often benefit from lower labor and production costs, allowing them to offer competitive pricing without compromising on quality. This is particularly appealing for businesses looking to optimize their production costs while maintaining high standards.

Moreover, many Chinese manufacturers are increasingly focusing on technological innovation. They invest in research and development to produce welding wires with enhanced properties, such as improved conductivity and resistance to oxidation. This dedication to innovation ensures that customers receive cutting-edge products that meet the demanding requirements of modern welding applications.

Quality Assurance and Standards

When choosing a manufacturer for 2mm copper welding wire, it is crucial to consider the quality assurance measures they have in place. Reputable Chinese manufacturers often adhere to international quality standards such as ISO 9001, which ensures that their production processes are consistently monitored and improved. Additionally, many manufacturers engage in third-party testing to validate the performance of their products, providing clients with peace of mind regarding the reliability of their welding materials.

Conclusion

In the realm of welding, the choice of materials significantly influences the final product's quality and durability. Two millimeter copper welding wire offers a combination of manageable dimensions and excellent performance, making it a popular choice across various industries. Chinese manufacturers play a pivotal role in supplying this essential material, leveraging competitive pricing and innovative production techniques to cater to a global market. As industries continue to evolve, the importance of high-quality welding wire will only grow, and with it, the significance of manufacturers who meet these demands. When selecting a supplier for copper welding wire, consideration of their quality standards and production capabilities is paramount for ensuring successful welding applications.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025