China E4043 Welding Rod Production and Manufacturing Insights for Quality Assurance

The Significance of China E4043 Welding Rods in Modern Manufacturing

In the realm of manufacturing and fabrication, welding plays a crucial role in creating strong and durable structures. Among the various welding materials available, the E4043 welding rod stands out as one of the most reputable choices, especially within Chinese factories specializing in its production. The E4043 welding rod is an aluminum silicon welding rod that is particularly well-suited for welding various aluminum alloys. This article explores the significance of the China E4043 welding rod factory, its production processes, and its impact on the welding industry.

Overview of E4043 Welding Rod

The E4043 welding rod is primarily composed of aluminum with a silicon content of about 5%. This specific alloying results in excellent fluidity when melted, making it ideal for feeding into welding machinery. The E4043 rod is known for its ability to produce welds that retain strength and flexibility, essential for applications in a wide range of industries, such as automotive manufacturing, aerospace, and construction. Moreover, its corrosion resistance makes it an excellent choice for components that will be exposed to harsh environmental conditions.

The Role of Chinese Factories

China has emerged as a global leader in the manufacturing of welding rods, including E4043. The factories that produce these rods are equipped with advanced technologies and adhere to stringent quality control measures. These facilities are often characterized by a high degree of automation, which ensures consistent quality and efficiency in production. Additionally, China's robust supply chain, combined with its ability to source raw materials at competitive prices, enables its factories to produce E4043 welding rods at a lower cost compared to manufacturers in many other countries.

Production Process

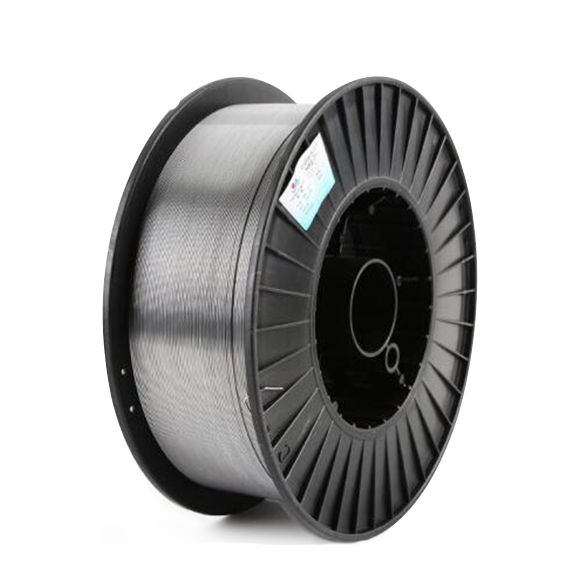

china e4043 welding rod factory

The production of E4043 welding rods begins with the careful selection of raw materials. The primary components—aluminum and silicon—are sourced and processed to meet specific purity standards. The production involves several stages, including melting the raw materials, alloying, and forging them into the desired rod shape. Once formed, the rods undergo a cooling process and are subsequently cut to the required lengths. Quality assurance tests, such as tensile strength and ductility tests, are conducted to ensure that the rods meet industry standards.

After the production phase, the rods are often coated or packaged to facilitate easy handling and transport. Many factories also engage in research and development to enhance the properties of their welding rods, making them even more suitable for specialized applications.

Impact on the Welding Industry

The availability of high-quality E4043 welding rods produced in China has had a transformative effect on the welding industry. By providing manufacturers with reliable materials at competitive prices, these factories play a pivotal role in reducing overall production costs. This, in turn, allows companies to invest resources into other critical areas such as innovation and workforce development.

Moreover, the E4043 rods have helped elevate the standards of welding practices. As these rods are used in various applications, they contribute to the overall improvement of welding techniques and the end quality of projects. Industries ranging from shipbuilding to high-speed rail significantly benefit from the efficiency and effectiveness that E4043 welding rods bring to their welding processes.

Conclusion

The China E4043 welding rod factory stands as a testament to the nation’s manufacturing prowess and innovation within the welding sector. As industries continue to evolve and seek stronger, lighter, and more resilient materials, the role of high-quality welding rods cannot be overstated. With ongoing advancements in production technology and adherence to international quality standards, Chinese factories are well-positioned to meet the growing demands of the global market. This not only ensures the continued success of the welding industry but also reinforces China's status as an essential player in the world of manufacturing.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025