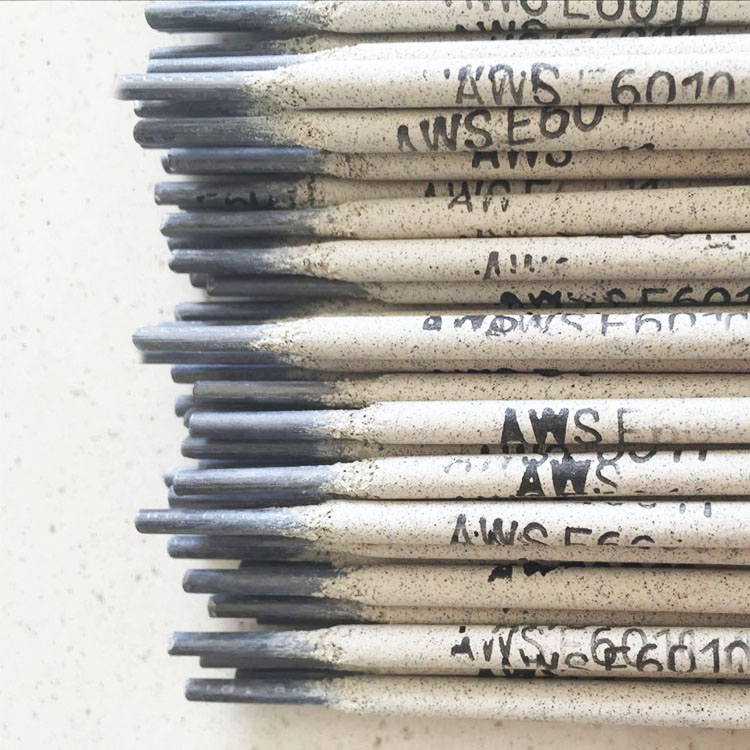

china electrode welding sticks manufacturer

The Rise of Chinese Electrode Welding Stick Manufacturers

In recent years, China has emerged as a global leader in the manufacturing of welding consumables, particularly electrode welding sticks. The country’s rapid industrial development, combined with its extensive manufacturing capabilities, has positioned it at the forefront of the welding industry. This article explores the factors contributing to the rise of Chinese electrode welding stick manufacturers and their impact on the global market.

The Growth of the Welding Industry in China

China's welding industry has experienced significant growth due to the booming construction, automotive, and manufacturing sectors. The demand for efficient and durable welding solutions has surged, leading to an increase in the production of welding materials, including electrode welding sticks. These sticks are essential for various welding processes, providing the necessary filler material and ensuring strong, reliable welds for a variety of applications.

High-Quality Production Standards

One of the key reasons for the success of Chinese manufacturers is their commitment to high-quality production standards. Many companies have adopted advanced manufacturing technologies and stringent quality control measures to ensure that their products meet international standards. The introduction of automated production lines, enhanced testing protocols, and skilled labor has allowed Chinese manufacturers to produce electrode welding sticks that are both reliable and cost-effective.

Diversification of Product Offerings

Chinese electrode welding stick manufacturers have also been successful in diversifying their product lines. They offer a wide range of welding sticks suitable for different applications, including mild steel, stainless steel, and cast iron welding. This diversification not only caters to the varying needs of domestic and international customers but also enhances competitiveness in the global market. By focusing on specific customer requirements and market trends, Chinese manufacturers are able to create tailored solutions that meet the demands of different industries.

china electrode welding sticks manufacturer

Export Competitiveness

China’s position as a leading exporter of electrode welding sticks is further strengthened by its ability to provide these products at competitive prices. The country benefits from the economies of scale and a developed supply chain, which lower production costs. Additionally, favorable government policies and trade agreements support the export of welding consumables, making Chinese products attractive to international buyers. Many countries now rely on Chinese manufacturers to supply high-quality welding sticks, resulting in a growing global footprint.

Challenges and Responses

Despite the remarkable growth, Chinese electrode welding stick manufacturers face several challenges, including increased competition from other countries and the need to comply with stricter environmental regulations. To overcome these hurdles, many manufacturers are investing in research and development to innovate and enhance their product offerings. They are also exploring sustainable manufacturing practices to minimize their environmental impact and align with global trends toward sustainability.

The Future of Chinese Welding Stick Manufacturers

Looking ahead, the future of Chinese electrode welding stick manufacturers appears promising. As global demand for welding consumables continues to rise, these manufacturers are poised to expand their market share further. The ongoing investment in technology and sustainability, coupled with a focus on quality and customer satisfaction, will surely enable them to maintain their competitive advantage.

In conclusion, Chinese electrode welding stick manufacturers have established themselves as key players in the global welding market. Their commitment to quality, product diversification, and competitive pricing has positioned them favorably against international competitors. As they navigate the challenges ahead, the ability to innovate and adapt will be crucial in sustaining this growth trajectory. The welding industry can expect to see continued advancements and an ongoing contribution from Chinese manufacturers in the years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025