Aluminum Electrode Suppliers in China for Quality and Performance Solutions

The Role of China in the Aluminium Electrode Supply Market

In the global market for aluminium electrodes, China has emerged as a dominant supplier, leveraging its extensive manufacturing capabilities and resource availability. Aluminium electrodes are crucial components in various industrial applications, particularly in the electrolysis process used for aluminium production, as well as in electrochemical reactions and batteries. The country's ability to produce high-quality aluminium electrodes at competitive prices has made it a go-to source for industries around the world.

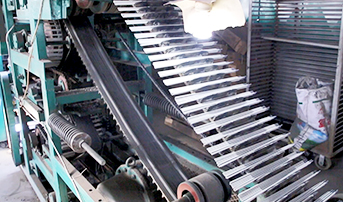

Manufacturing Capabilities

China's manufacturing infrastructure is one of its greatest assets. The country boasts numerous state-of-the-art facilities that use advanced technologies and equipment to produce aluminium electrodes. This capability allows manufacturers to maintain high production volumes while ensuring quality consistency. The integration of automation and robotics in the manufacturing process has not only enhanced efficiency but also reduced operational costs, making Chinese aluminium electrodes highly competitive in the international market.

Resource Availability

Another factor contributing to China’s success as an aluminium electrode supplier is its access to raw materials. As a leading producer of aluminium, the country has a well-established supply chain that includes bauxite mining and alumina refining. This self-sufficient production cycle enables manufacturers to minimize costs associated with raw material procurement, further enhancing their competitiveness. With abundant resources, Chinese suppliers can meet the growing global demand for aluminium electrodes without significant disruptions.

Quality Assurance

Chinese manufacturers understand the importance of quality in the aluminium electrode market. Many suppliers adhere to international quality standards and invest in rigorous testing processes to ensure that their products meet specific requirements. This commitment to quality has helped Chinese aluminium electrodes gain recognition in various industrial applications, from energy storage systems to metallurgical processes.

china electrodo de aluminio supplier

Environmental Considerations

In recent years, there has been a heightened focus on sustainability and environmental responsibility in the manufacturing sector. Chinese manufacturers are increasingly adopting green practices in their production processes. This includes the implementation of energy-efficient technologies, waste recycling measures, and compliance with environmental regulations. As a result, Chinese aluminium electrode suppliers are not only able to meet customer demands but also align with global sustainability trends.

Global Trade and Supply Chains

China’s role as a leading aluminium electrode supplier is strengthened by its extensive trade networks. The country exports to various regions, including Europe, North America, and Asia-Pacific. These established supply chains facilitate timely delivery and responsive customer service, which are essential in today’s fast-paced industrial environment. Furthermore, the Belt and Road Initiative has enhanced connectivity and trade volume, opening new markets for Chinese aluminium products.

Challenges and Opportunities

Despite its dominant position, the Chinese aluminium electrode industry faces challenges, including trade tensions and fluctuations in raw material prices. However, these challenges also present opportunities for innovation and strategic expansion. Companies are increasingly investing in research and development to create more efficient and advanced aluminium electrodes, as well as exploring new markets to offset potential losses from tariffs or trade restrictions.

Conclusion

China's role as a supplier of aluminium electrodes is multifaceted, driven by its robust manufacturing capabilities, resource availability, commitment to quality, and innovative approaches to sustainability. As the global demand for aluminium continues to rise, particularly in energy and automotive sectors, Chinese suppliers are well-positioned to remain at the forefront of the aluminium electrode market. For industries seeking reliable and high-quality aluminium electrodes, forging partnerships with Chinese suppliers can provide significant advantages in terms of cost, efficiency, and innovation.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025