china electrodos bridge 6013 3/32 factories

The China Electrodes Bridge 6013 3/32 Factories A Beacon of Innovation in Welding Technology

In today's industrial landscape, the demand for efficient and reliable welding solutions continues to grow. One such advancement in this field is the emergence of specialized manufacturing plants focused on producing high-quality electrodes for arc welding processes. Among them, the China Electrodes Bridge 6013 3/32 factories stand out, driven by innovation, quality craftsmanship, and a commitment to meeting the diverse needs of global customers.

Understanding 6013 Electrodes

Before delving into the factories themselves, it's essential to understand what 6013 electrodes are and why they are so significant in the welding industry. The designation 6013 refers to a specific type of mild steel electrode designed for welding carbon steel with a yield strength of around 60,000 psi. The 3/32 size indicates the diameter of the rod, which measures approximately 2.4 mm. These electrodes are known for their versatility, ease of use, and ability to produce clean, strong welds with excellent arc stability.

6013 electrodes are especially favored in various applications, including automotive repair, construction, and manufacturing. They are also suitable for both AC and DC welding processes, making them a go-to choice for many welders, whether they are professionals or enthusiasts. The demand for such versatile welding solutions has led to a surge in the establishment of specialized factories in China.

The Rise of Chinese Manufacturing

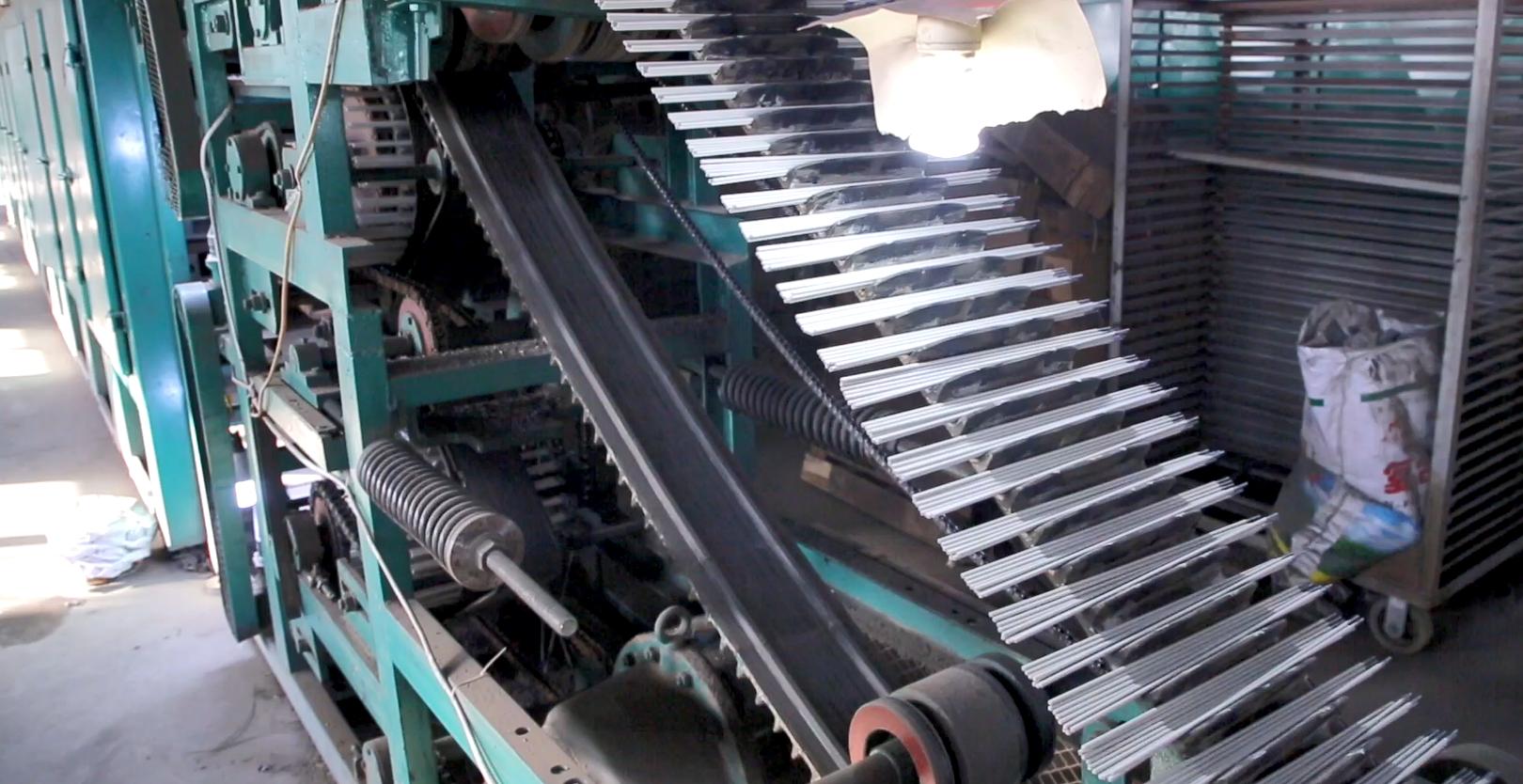

China has become a global manufacturing powerhouse, renowned for its ability to produce a vast array of goods at competitive prices. This trend extends to the production of welding electrodes, where factories specialized in the manufacture of 6013 electrodes have emerged as key players. These factories combine advanced technologies with skilled labor to produce electrodes that meet international standards for quality and performance.

One of the primary advantages of manufacturing in China is the country's extensive supply chain infrastructure. Access to raw materials, alongside a robust logistics network, allows these factories to maintain efficiency while minimizing costs. Additionally, the competitive labor market ensures that skilled workers are available to produce high-quality products.

china electrodos bridge 6013 3/32 factories

Quality Control and Innovation

Quality control is paramount in the production of welding electrodes. Factories specializing in the 6013 3/32 electrode implement stringent testing and quality assurance measures at every stage of the manufacturing process. This includes sourcing high-grade materials, closely monitoring production processes, and conducting rigorous inspections of the finished products.

Moreover, innovation is a core focus for these factories. They continuously invest in research and development to enhance the properties of their electrodes, aiming to improve characteristics such as arc stability, slag removal, and weld appearance. These advancements are crucial in meeting the evolving demands of various industries, as welders seek electrodes that can provide superior performance under diverse conditions.

Meeting Global Demand

With the increasing globalization of trade, Chinese factories have positioned themselves to meet the rising demand for 6013 electrodes worldwide. They not only cater to domestic markets but also export their products to countries across Asia, Europe, North America, and beyond. This expansion into global markets is supported by a commitment to customer service and product availability, ensuring that clients receive their orders promptly.

Furthermore, many factories are beginning to adhere to international certification standards, such as ISO 9001, which enhances their credibility and fosters trust among global customers. This adherence to international quality standards is instrumental in competing with other established manufacturers around the world.

Conclusion

In conclusion, the China Electrodes Bridge 6013 3/32 factories exemplify the strength and innovation of Chinese manufacturing in the welding industry. With a focus on quality, efficiency, and global outreach, these factories not only produce a vital welding component but also contribute to the overall advancement of technology in the field of welding. As the industry continues to evolve, these factories are well-positioned to meet the future challenges and demands, further solidifying their role as key players in the global marketplace.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025