China E7018 3/32 Electrodes Manufacturing and Supply Chain Overview

The Evolution and Significance of E7018 Electrodes in China’s Welding Industry

In the dynamic landscape of modern manufacturing, the welding process plays a vital role in various industries, from construction to automotive. Among the numerous welding electrodes available, the E7018 electrode has gained prominence due to its excellent properties and versatility. In China, the production of E7018 electrodes, particularly the 3/32 inch size, has become a focal point for various factories striving to meet the rising demands of the global market.

Understanding E7018 Electrodes

E7018 electrodes are low hydrogen welding rods primarily used for manual arc welding. The designation E7018 reveals key details E stands for electrode, 70 indicates the minimum tensile strength of 70,000 psi, and 18 designates the type of coating. The coating contains iron powder and other deoxidizing agents, providing a stable arc and minimizing the risk of hydrogen embrittlement in the weld metal. This makes E7018 electrodes particularly suitable for welding high-strength steels, which are common in critical applications such as pressure vessels, bridges, and structural components.

The size of the electrode, in this case, 3/32 inches, is also significant. This diameter allows for excellent control and precision in welding, which is essential for delicate or specialized tasks. The 3/32 size is especially favored for its versatility across various welding techniques, including stringer beads and whip techniques.

The Chinese Manufacturing Landscape

China’s factories have evolved considerably over the years, thanks to advancements in technology and increased investment in infrastructure. The production of E7018 electrodes is no exception. Numerous manufacturers have emerged, leveraging modern techniques to enhance the quality and performance of these electrodes. The manufacturing process often involves stringent quality control measures, ensuring that each batch meets international standards.

China's ability to produce E7018 electrodes at a competitive price has also made it a key player in the global market. With a well-established supply chain and extensive resources, these manufacturers can deliver high-quality products efficiently. This competitive edge has allowed Chinese companies to export E7018 electrodes worldwide, providing essential materials for various welding applications.

china electrodos e7018 3/32 factories

Quality Standards and Innovations

To compete in the international arena, Chinese manufacturers are increasingly focusing on innovation and quality. Factories are adopting advanced manufacturing techniques, such as automated production lines and quality assurance systems, to ensure that their E7018 electrodes perform reliably. Innovations in coating materials and production methods have also contributed to improvements in the arc stability and ease of use of these electrodes.

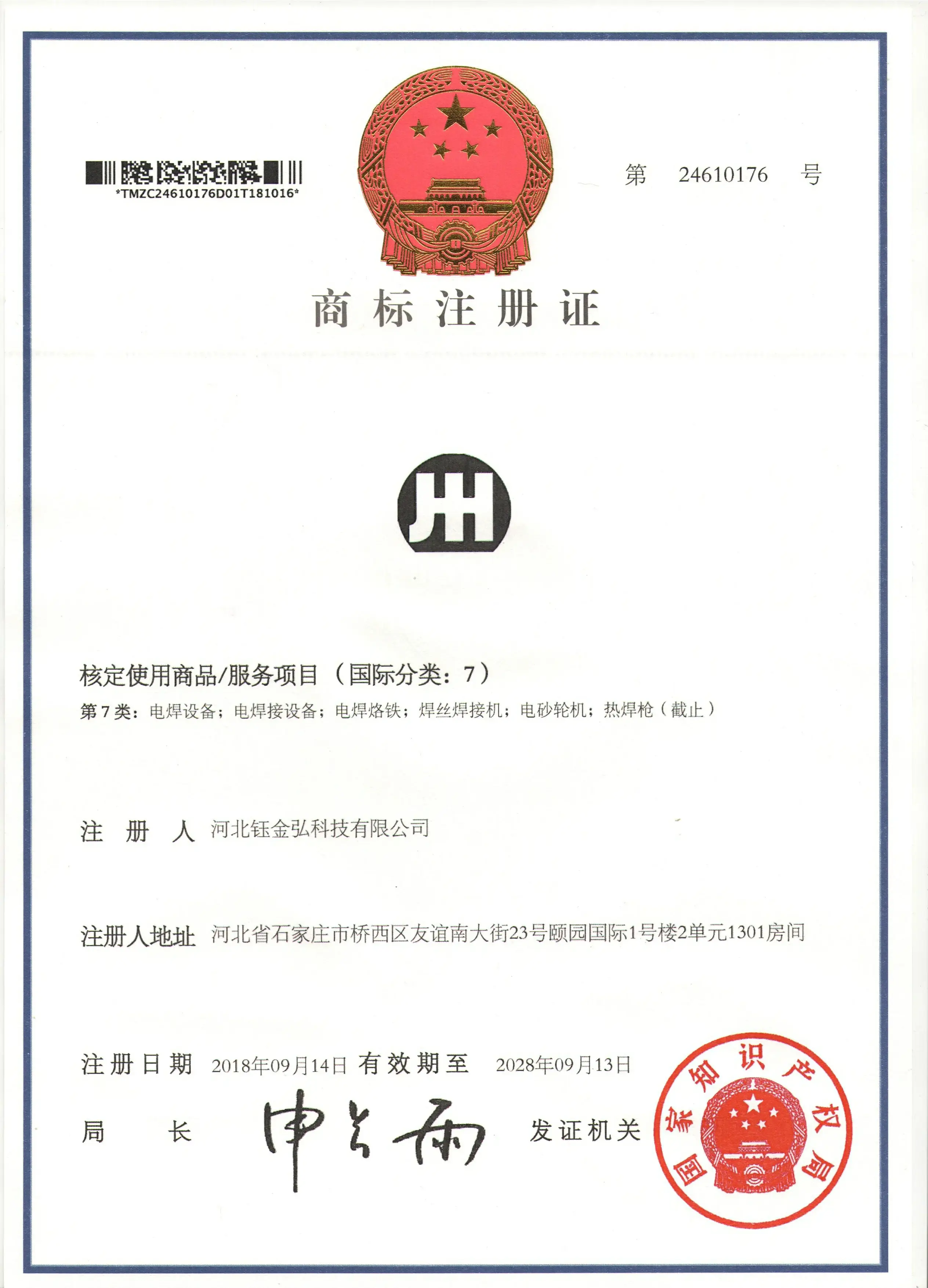

Moreover, many manufacturers are obtaining certifications from global standards organizations, further establishing their credibility. This focus on quality not only satisfies domestic requirements but also boosts their appeal in overseas markets, where welding quality is imperative.

Applications and Industry Impact

The applications of E7018 electrodes in China extend across various industries. In the construction sector, they are crucial for building robust infrastructures, such as bridges and skyscrapers. Their versatility also finds use in the manufacturing of pressure vessels, shipbuilding, and automotive industries, where safety and strength are paramount.

The impact of E7018 electrodes goes beyond individual industries. By providing the necessary materials for quality welding, these electrodes contribute to the overall efficiency and safety of numerous construction and manufacturing projects. As China continues to advance in its manufacturing capabilities, the importance of E7018 electrodes only grows, reinforcing their status as a staple in the welding industry.

Conclusion

The growth of E7018 electrode manufacturing in China illustrates the intersection of innovation, quality, and market demand. With its proven capabilities in welding applications, the E7018, especially the 3/32 inch variant, stands out as an essential tool for manufacturers and welders alike. As Chinese factories continue to pioneer advancements in this field, they not only strengthen the domestic market but also play a critical role in the global economy, ensuring that high-quality welding solutions are both accessible and reliable. With ongoing investments in technology and quality assurance, the future of E7018 electrodes in China looks promising, underlining their significance in various industries worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025