Top Manufacturers of Galvanized Welding Rods in China for Quality Solutions

The Landscape of Galvanized Welding Rod Manufacturers in China

Galvanized welding rods play a crucial role in different industries, serving as essential components in various welding processes. China, being a global manufacturing powerhouse, has established itself as a leading producer of galvanized welding rods, catering to both domestic and international markets. The sheer scale, technological advancements, and diverse offerings within this sector make it an intriguing subject of exploration.

Understanding Galvanized Welding Rods

Before delving into the specifics of manufacturers, it's imperative to understand what galvanized welding rods are. These rods are coated with a layer of zinc, which provides protection against corrosion. This characteristic is particularly valuable in environments where the risk of rusting is high. Galvanized welding rods are primarily used in welding applications involving ferrous and non-ferrous metals, ensuring strong and durable joints.

China's Dominance in Production

China is home to numerous manufacturers specializing in galvanized welding rods. The country's vast resources, skilled labor, and enhanced production capabilities contribute to its prominent position in the global market. As of recent years, it is estimated that China accounts for a significant percentage of the world’s galvanized welding rod production. This dominance stems from the combination of cost-effective manufacturing processes and the ability to scale production to meet varying demands.

Key Players in the Market

Within China, several manufacturers have emerged as leaders in the galvanized welding rod industry. Companies like Shanghai General Engineering, Jiangsu Shagang Group, and Anshan Iron and Steel Group are among the notable names. These manufacturers not only focus on the domestic market but also export their products globally, enhancing their market presence.

Each of these companies employs advanced manufacturing technologies to ensure the quality and consistency of their products. They invest heavily in research and development to innovate and improve their welding rods, providing clients with materials that meet international standards. This commitment to quality has earned them a solid reputation in the welding industry.

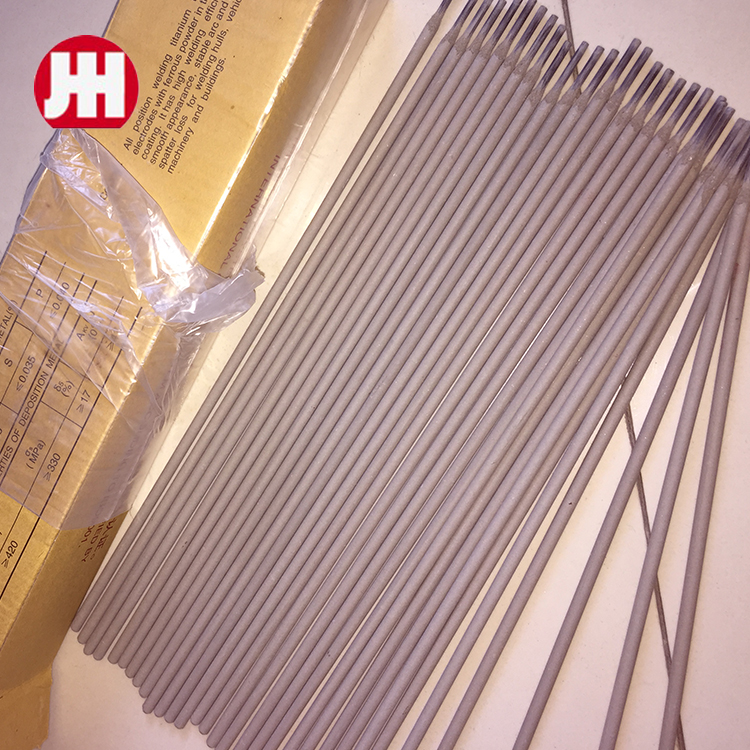

china galvanized welding rod manufacturers

Quality Standards and Certifications

In recent years, quality standards have become increasingly important in the manufacturing process. Companies are now required to adhere to stringent quality control measures to ensure their products are reliable and safe for use. Many Chinese manufacturers of galvanized welding rods have obtained various international certifications, such as ISO 9001, ensuring their products meet global quality standards. This focus on quality not only helps in gaining customer trust but also facilitates entry into more competitive markets.

Environmental Considerations

With growing concerns about environmental sustainability, many manufacturers in China are also making strides towards eco-friendly production methods. This includes adopting greener technologies, reducing waste, and minimizing emissions during the manufacturing process. By implementing these practices, they not only comply with local regulations but also position themselves favorably in the global market, where consumers are increasingly favoring sustainable products.

Trends in the Industry

The galvanized welding rod market in China is witnessing various trends that are shaping its future. One significant trend is the increasing demand for automation in manufacturing processes. As manufacturers seek to enhance efficiency and reduce costs, the integration of automation and robotics in production lines is becoming more common.

Additionally, the rise of green construction and commitment to renewable energy sources are leading to more robust demand for durable welding materials, further supporting the growth of the galvanized welding rod market.

Conclusion

In summary, the landscape of galvanized welding rod manufacturers in China is marked by innovation, quality, and responsiveness to market demands. With numerous companies dedicated to producing high-quality welding materials, China continues to be a key player on the global stage. As the industry evolves, manufacturers are likely to adapt to emerging trends, ensuring they remain competitive while also contributing to a more sustainable future. Whether for local use or international export, galvanized welding rods from China are becoming synonymous with reliability and quality in the welding industry.

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025