china mig tig stick welding factory

The Landscape of Welding Technology in China MIG, TIG, and Stick Welding

Welding is a fundamental process in manufacturing and construction, and its importance cannot be overstated. In China, which stands as one of the largest manufacturing hubs globally, the demand for welding technology continues to rise. Among the various welding techniques, MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding are the most prominent methods utilized across industries. This article explores the intricacies of these processes and highlights the role of Chinese factories in their production.

Understanding Welding Techniques

MIG welding, also known as Gas Metal Arc Welding (GMAW), employs a continuous feed of a filler metal electrode and an inert gas shield. This method is favored for its speed and efficiency, making it ideal for production lines and large-scale projects. Similarly, TIG welding, or Gas Tungsten Arc Welding (GTAW), is recognized for its precision and control, utilizing a non-consumable tungsten electrode. It is commonly used for thinner materials and applications requiring clean finishes, such as in the aerospace and automotive industries.

On the other hand, stick welding, or Shielded Metal Arc Welding (SMAW), is one of the oldest and simplest welding processes. It employs a consumable electrode coated in flux, which not only provides a filler material but also protects the molten weld from contamination. Although stick welding is considered less sophisticated than MIG or TIG, it remains indispensable, particularly in outdoor and rugged applications due to its versatility.

The Role of Chinese Factories

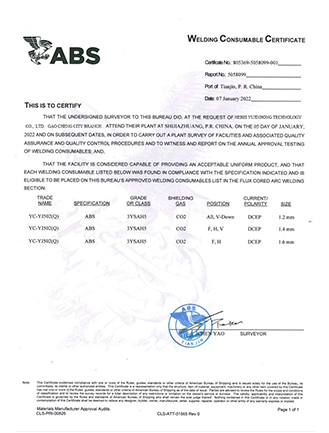

China's robust manufacturing sector influences the global welding market significantly. Many factories are devoted to producing welding equipment and consumables for MIG, TIG, and stick welding. These factories leverage advanced technologies to enhance productivity and ensure the quality of their products. By submitting to rigorous standards, they help in gaining international certifications, which boosts the competitiveness of their products on a global scale.

Moreover, many Chinese welding equipment manufacturers focus on research and development to innovate and improve welding technology. They introduce automated solutions that integrate Artificial Intelligence and robotics into the welding process, which not only accelerates production but also enhances precision and reduces human errors. The evolution of welding machines to include features such as inverter technology and digital control systems exemplifies the country's commitment to modernizing traditional techniques.

china mig tig stick welding factory

Competitive Pricing and Quality

One of the most significant advantages of sourcing MIG, TIG, and stick welding equipment from Chinese factories is their competitive pricing. The relatively lower production costs in China enable manufacturers to offer high-quality products at attractive prices. This factor appeals to businesses globally, particularly in developing countries where budget constraints are prevalent.

However, there is a common misconception that lower prices equate to lower quality. Many Chinese manufacturers uphold stringent quality control measures, ensuring that their products meet or even exceed global standards. The renowned quality of Chinese welding machines has been validated by numerous international partnerships and collaborations, further solidifying China's position in the global welding industry.

The Future of Welding in China

As China continues to evolve as a tech hub, the future of welding technology appears promising. The increasing demand for automation and smart technologies is likely to shape the next generation of welding solutions. Manufacturers are expected to invest more in research and development, exploring areas like hybrid welding processes that combine the advantages of MIG, TIG, and stick welding techniques into more efficient applications.

Moreover, the trend towards sustainability will influence the welding industry. Manufacturers are becoming more conscious of energy consumption and waste management in welding processes, driving innovations that minimize the environmental impact.

Conclusion

In conclusion, China’s manufacturing prowess extends significantly into the field of welding technologies, with MIG, TIG, and stick welding forming the backbone of its diverse industries. Through the diligent efforts of its factories, China not only meets domestic demand but also supplies welding equipment to international markets, affirming its status as a global leader in welding technology. As the industry continues to advance, embracing automation and sustainable practices, the future of welding in China looks bright, ensuring its continued relevance in the global manufacturing landscape.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025