China MIG Welder Wire for Optimal Welding Performance and Durability

Understanding China MIG Welder Wire Quality, Variety, and Applications

In the realm of welding, one of the most vital components is the welding wire itself, especially for Metal Inert Gas (MIG) welding processes. Among the many sources of welding wires globally, China has emerged as a significant player, supplying a vast range of MIG welder wires known for their quality and affordability. In this article, we will explore the types of MIG welder wire produced in China, their properties, and their applications across various industries.

Types of MIG Welder Wire

Chinese manufacturers produce a variety of MIG welding wires that cater to different needs and welding processes. The most common types include

1. ER70S-6 This is one of the most popular types of MIG welding wire used for general-purpose welding. It is suitable for welding carbon steel and is known for its strong welds and excellent deoxidation properties.

2. ER308L Primarily used for stainless steel welding, this wire provides good corrosion resistance and is ideal for applications that require high strength and durability.

4. Flux-cored Wires These are designed to be used with or without shielding gas, providing versatility in different environments, especially outdoors where wind can affect shielding.

Quality Assurance

Chinese MIG welder wires are subjected to stringent quality control processes. Most reputable manufacturers obtain certifications such as ISO 9001, which ensures that their products meet international standards. This focus on quality is evident in the great care taken to control the chemical composition of the wires to ensure optimal mechanical properties.

Also, advanced manufacturing techniques, such as precise wire drawing and careful alloying, contribute to the overall consistency and reliability of the wire. Buyers can typically find detailed specifications and test results available from suppliers, which further affirms the quality of these products.

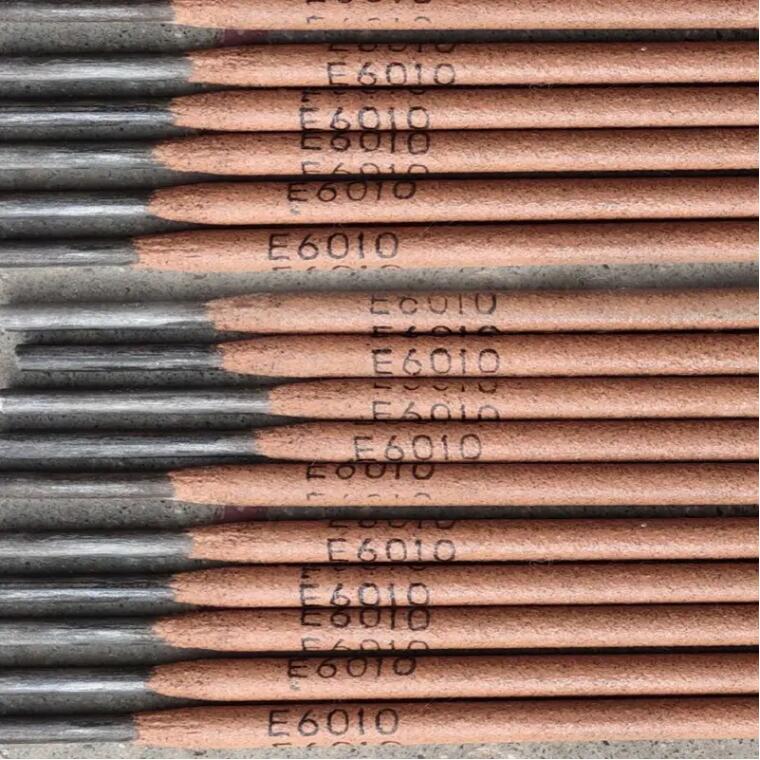

china mig welder wire

Cost-Effectiveness

One of the primary advantages of purchasing MIG welder wire from China is the cost-effectiveness. Due to the lower production costs and economies of scale, Chinese manufacturers can offer competitive prices without compromising quality. This has made it an attractive option for businesses looking to maintain economical operations while not sacrificing the quality of their welding projects.

Applications Across Industries

The versatility of Chinese MIG welder wires allows them to be utilized across various industries. Here are a few notable applications

1. Automotive Industry MIG welding is extensively used in car manufacturing and repairs. With the lightweight materials used in modern vehicles, such as aluminum and high-strength steel, the appropriately chosen MIG wire ensures durable and reliable joints.

2. Construction Building structures often require robust welding solutions. Chinese MIG welder wires provide the strength and resistance needed for constructing buildings and other infrastructure.

3. Shipbuilding In the marine industry, particularly for ships and yachts, the use of aluminum and stainless steel is prevalent. The corresponding MIG welding wires from China have made it feasible to safely craft durable vessels capable of enduring harsh marine environments.

4. Fabrication Shops For metal fabrication projects, having a reliable supply of MIG welding wire is crucial. Many small to medium-sized fabrication shops rely on Chinese manufacturers to fulfill their needs for diverse wire types.

Conclusion

China's influence in the global welding market continues to expand, particularly in the production of MIG welder wire. With a myriad of options tailored to specific welding applications, these products stand out for their quality, affordability, and diverse industrial applications. As industries evolve and the demand for different welding solutions grows, Chinese manufacturers are poised to remain key players, ensuring that welders worldwide have access to the materials they need to succeed in their crafts. When selecting MIG welder wire, consideration of quality, wire type, and application is essential to achieving optimal welding results and maintaining project integrity.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025