china mig welding co2 wire factory

The Evolution and Importance of CO2 Welding Wire Factories in China

In recent years, China has emerged as a powerhouse in manufacturing, particularly in the welding industry. Among the various techniques employed in this field, CO2 welding, also known as MIG (Metal Inert Gas) welding, has gained significant traction. The combination of advanced manufacturing capabilities and the high demand for quality welding products has led to the establishment and growth of numerous CO2 welding wire factories across the nation.

The Evolution and Importance of CO2 Welding Wire Factories in China

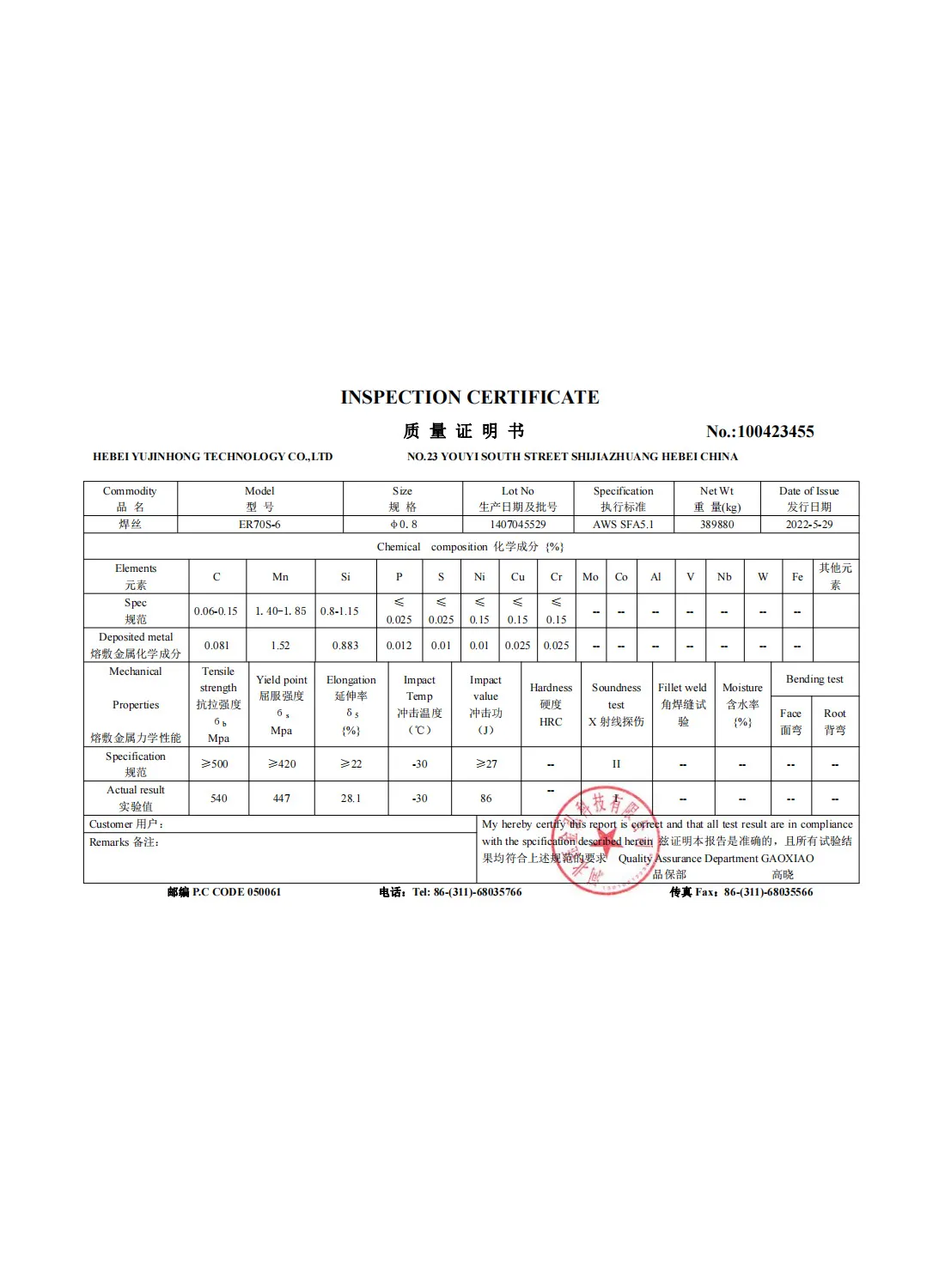

The production of CO2 welding wires involves several critical stages, including the sourcing of raw materials, drawing and coating of the wire, and stringent quality control processes. Chinese factories have embraced modern technologies and automated production lines, ensuring that they remain competitive in the global market. These advancements not only enhance production efficiency but also maintain consistent quality across batches of welding wire.

china mig welding co2 wire factory

Moreover, environmental concerns have prompted manufacturers to adopt more sustainable practices. Many Chinese factories are now focusing on eco-friendly materials and processes, aiming to reduce their carbon footprint. This shift not only aligns with global environmental standards but also appeals to increasingly eco-conscious consumers around the world.

One notable aspect of the CO2 welding wire industry in China is its ability to rapidly adapt to changes in market demand. With a strong emphasis on research and development, factories are continuously innovating to produce wires that cater to varying welding requirements. This flexibility allows manufacturers to provide specialized products for niche markets, thus expanding their reach and profitability.

Additionally, China's strategic investments in infrastructure and logistics have significantly benefited CO2 welding wire factories. With efficient transportation networks, manufacturers can easily distribute their products both domestically and internationally. This logistical advantage enables them to respond quickly to customer needs, ensuring that the demand for welding materials is met promptly.

In conclusion, CO2 welding wire factories in China play a vital role in the global welding industry. Their ability to produce high-quality, reliable welding wire has positioned them as key players not only in domestic markets but also on the international stage. As technology continues to evolve and environmental considerations remain paramount, these factories are well-equipped to adapt and thrive, securing their place in the future of welding. The ongoing commitment to quality, innovation, and sustainability ensures that China's manufacturing prowess will continue to lead the way in the welding sector for years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025