china mig welding co2 wire suppliers

Exploring CO2 Welding Wire Suppliers in China

In the world of industrial manufacturing and welding, the choice of materials and equipment plays a crucial role in ensuring quality and efficiency. One significant component in the realm of metal joining technologies is CO2 welding wire, particularly MIG (Metal Inert Gas) welding wire. This article delves into the landscape of CO2 welding wire suppliers in China, where an abundance of manufacturers and suppliers caters to both domestic and international markets.

Understanding MIG Welding and CO2 Wire

MIG welding is a semi-automatic or automatic process that uses a continuously fed wire electrode and a shielding gas to protect the weld pool from contamination. The use of CO2 as a shielding gas in MIG welding primarily serves to stabilize the arc and enhance the quality of the weld. CO2 welding wire is typically made from mild steel, making it a favorite among welders for applications that require strong and durable joints.

The Demand for CO2 Welding Wire

China's booming industrial sector has led to a significant demand for high-quality welding consumables, including CO2 welding wire. As industries such as automotive, shipbuilding, construction, and manufacturing expand, the need for efficient and reliable welding solutions has never been greater. CO2 welding wire has emerged as a preferred choice due to its cost-effectiveness and ease of use, thereby accelerating its consumption across various industries.

Key Features of CO2 Welding Wire Suppliers in China

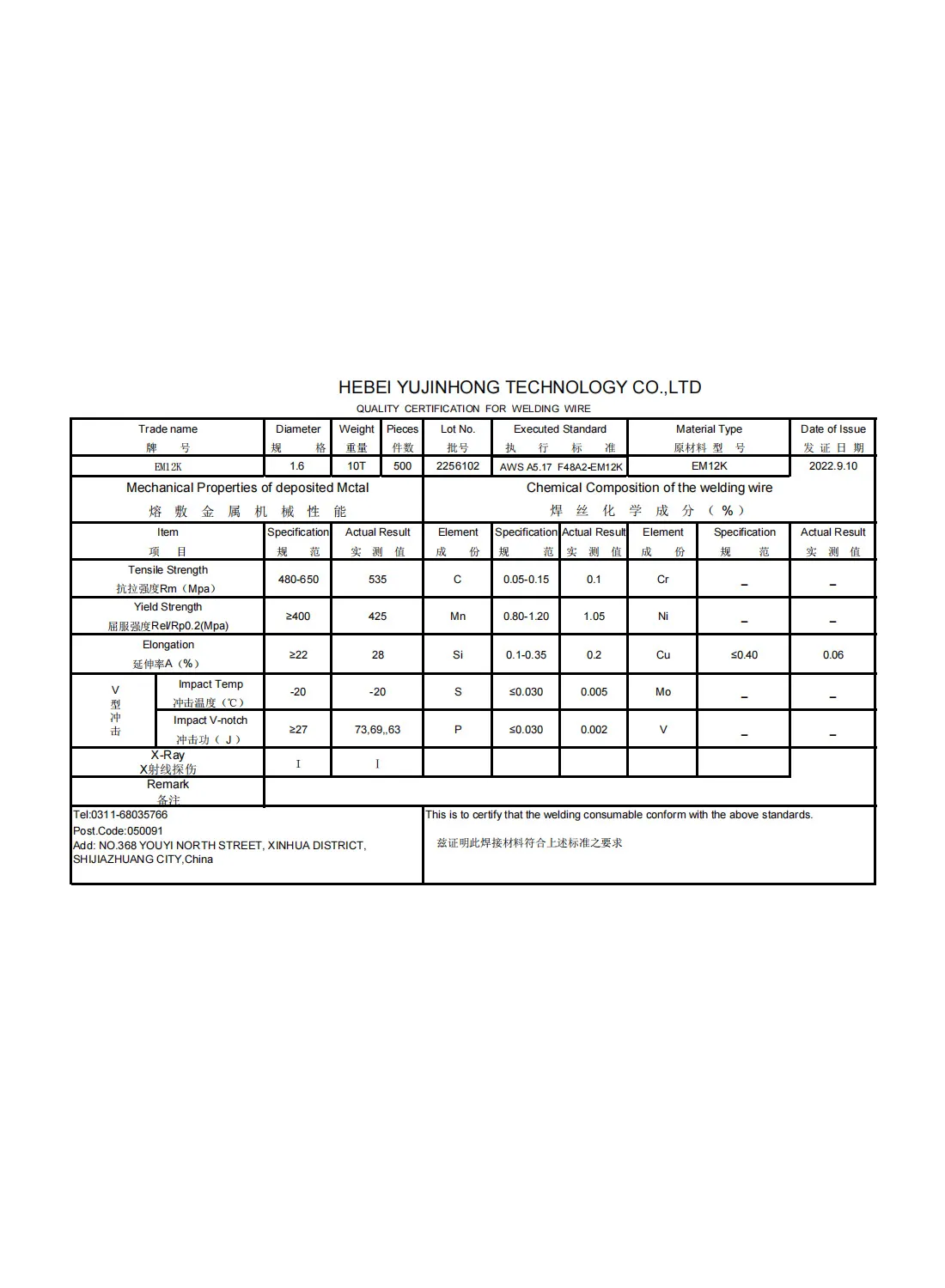

1. Diverse Product Range Suppliers in China offer a wide variety of CO2 welding wires that cater to different welding requirements, including different diameters, chemical compositions, and mechanical properties. This diversity enables manufacturers to choose the appropriate wire for specific applications.

2. Quality Assurance Many Chinese suppliers adhere to international standards and certifications, ensuring the quality of their welding consumables. Certifications such as ISO 9001 often serve as a benchmark for quality management systems, instilling confidence in the products offered.

china mig welding co2 wire suppliers

3. Competitive Pricing One of the significant advantages of sourcing CO2 welding wire from China is competitive pricing. Cost-effective manufacturing processes, coupled with a strong supply chain network, allow suppliers to offer affordable products without compromising on quality.

4. Innovative Technology Chinese manufacturers are increasingly investing in advanced technologies and automated systems to improve production efficiency and product quality. Continuous research and development efforts enable suppliers to innovate and provide better welding solutions to their clients.

5. Export Capabilities With China's position as a leading exporter of industrial products, many CO2 welding wire suppliers have developed robust international networks. They are proficient in handling logistics, customs regulations, and export documentation, making it easier for global buyers to source products.

Challenges Faced by Suppliers

Despite the numerous advantages, CO2 welding wire suppliers in China face several challenges. The market is highly competitive, with numerous players vying for attention. Additionally, fluctuating raw material prices can affect the cost of production and ultimately the pricing structure for end-users. Ensuring consistent quality amid rapid production schedules also poses a challenge for many manufacturers.

Conclusion

The landscape of CO2 welding wire suppliers in China is vibrant and dynamic, marked by a variety of choices in wire specifications and competitive pricing. As industries around the world continue to evolve and demand high-quality welding solutions, Chinese suppliers are well-positioned to meet these needs through their innovative approaches and commitment to quality. For businesses seeking reliable and cost-effective welding wire, exploring the vast offerings from China can lead to promising partnerships and successful welding operations.

In summary, the relationship between suppliers and manufacturers of CO2 welding wire in China represents an integral part of the global manufacturing ecosystem, contributing significantly to the quality and efficiency of production processes worldwide.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025