China MIG Welding Wire 20kg Spools Manufacturers and Suppliers for Quality Welding Solutions

The Landscape of MIG Welding Wire Production in China

China has established itself as a global leader in various manufacturing sectors, and one such area of expertise is the production of MIG (Metal Inert Gas) welding wire. The demand for high-quality welding wire is fueled by the growing construction and automotive industries, both in China and around the world. This article explores the factories producing MIG welding wire in 20kg spools, their technological advancements, quality standards, and contribution to the global market.

Overview of MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a widely utilized welding technique that employs a continuous feeding wire to create a weld. This method ensures a rapid, efficient, and clean welding process, making it a preferred choice for many industrial applications. The wire used in MIG welding is typically made of materials like carbon steel, stainless steel, or aluminum, offering various properties to suit specific welding needs.

China's Role in MIG Welding Wire Production

Chinese factories that manufacture MIG welding wire have capitalized on the burgeoning global demand. These facilities are equipped with modern production technologies, capable of producing high-quality welding wire in large volumes. The country's competitive labor market and robust supply chain further enhance its appeal as a manufacturing hub.

Most of the MIG welding wire factories in China are equipped with advanced machines that automate the manufacturing process. This automation not only increases efficiency but also maintains consistency in the quality of the wire produced. Additionally, many of these factories implement rigorous quality control measures throughout the production process, ensuring that the final product meets international standards.

Quality Standards and Certification

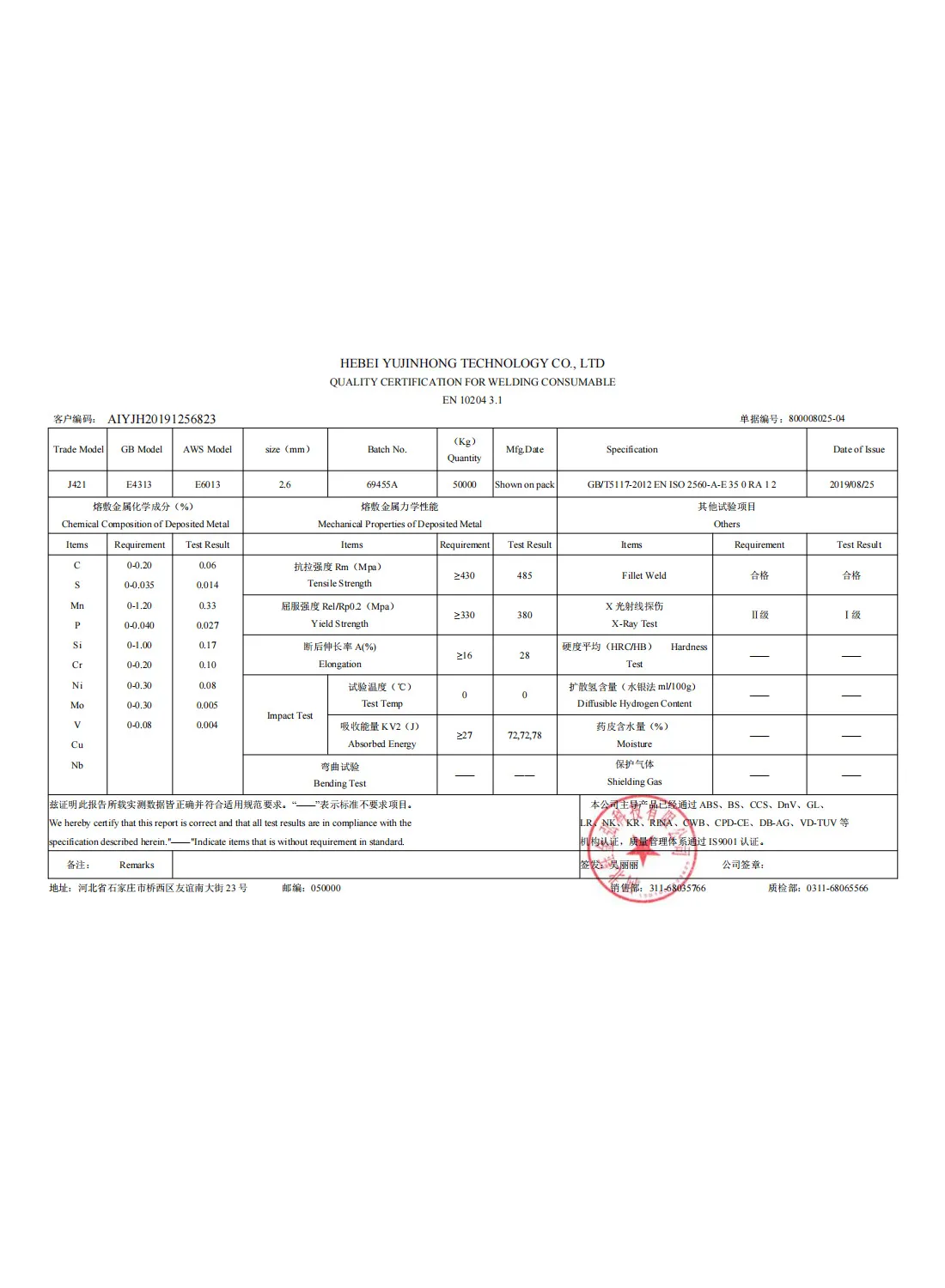

One of the key aspects that set Chinese MIG welding wire manufacturers apart is their adherence to stringent quality standards. Many factories are certified by international bodies such as ISO (International Organization for Standardization) and ASME (American Society of Mechanical Engineers). These certifications ensure that the welding wire produced meets specific safety and performance criteria, which is essential for industries such as construction, automotive, and shipbuilding.

china mig welding wire 20kg spool factories

Moreover, the raw materials used in the production of MIG welding wire are sourced from reputable suppliers

. Manufacturers often perform detailed tests on these materials to guarantee their properties align with the required standards. This focus on quality at every stage of production solidifies China's position in the global market for welding consumables.Environmental Considerations

With the increasing awareness of environmental issues, many Chinese welding wire factories are adopting greener manufacturing practices. This includes reducing emissions, minimizing waste, and recycling materials whenever possible. Some factories have even invested in state-of-the-art filtration systems to minimize pollutants, ensuring that their operations are not only efficient but also environmentally friendly.

Global Market Impact

The contribution of Chinese MIG welding wire factories to the global market is significant. They supply welding wire not only within China but also to various countries around the world. With their competitive pricing and reliable quality, Chinese manufacturers have become preferred suppliers for many businesses in need of welding consumables.

In recent years, as the industry continues to evolve, these factories are also emphasizing research and development. Innovations in welding wire formulations and enhancements in delivery systems are helping them stay ahead of market trends and meet the ever-changing demands of their customers.

Conclusion

In summary, China's factories producing MIG welding wire in 20kg spools play an integral role in the global welding industry. Their advanced manufacturing technologies, strict adherence to quality standards, and responsiveness to environmental concerns position them as vital contributors to the market. As industries worldwide continue to rely on efficient and high-quality welding solutions, Chinese manufacturers are poised to maintain their leading status in this essential sector.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025