China's 3/32 Electrode Production Factories and Their Impact on the Global Market

The Dynamics of China’s 3/32 Electrodes Manufacturing Industry

China has cemented its position as a powerhouse in the global manufacturing sector, especially in the production of welding electrodes. Among the diverse range of welding electrodes, 3/32-inch electrodes are particularly significant due to their versatility and application in various industries such as construction, automotive, and shipbuilding. This article explores the key aspects of the manufacturing landscape for 3/32 electrodes in China, focusing on factory capabilities, technological advancements, and market trends.

Overview of 3/32 Electrodes

3/32-inch electrodes are widely used in shielded metal arc welding (SMAW) processes, characterized by their size and the welding processes they facilitate. The size provides an excellent balance between penetration and arc control, making them ideal for welding thin materials and root passes in thicker joints. As a result, the demand for high-quality 3/32 electrodes has been on the rise in both domestic and international markets.

Factory Capabilities

China boasts a vast network of factories dedicated to the production of welding electrodes, with many specializing in the 3/32-inch variety. These factories are equipped with advanced machinery, allowing for mass production while maintaining stringent quality standards. The manufacturing process typically involves wire drawing, coating, and packaging, all of which are optimized to ensure efficiency and reduce costs.

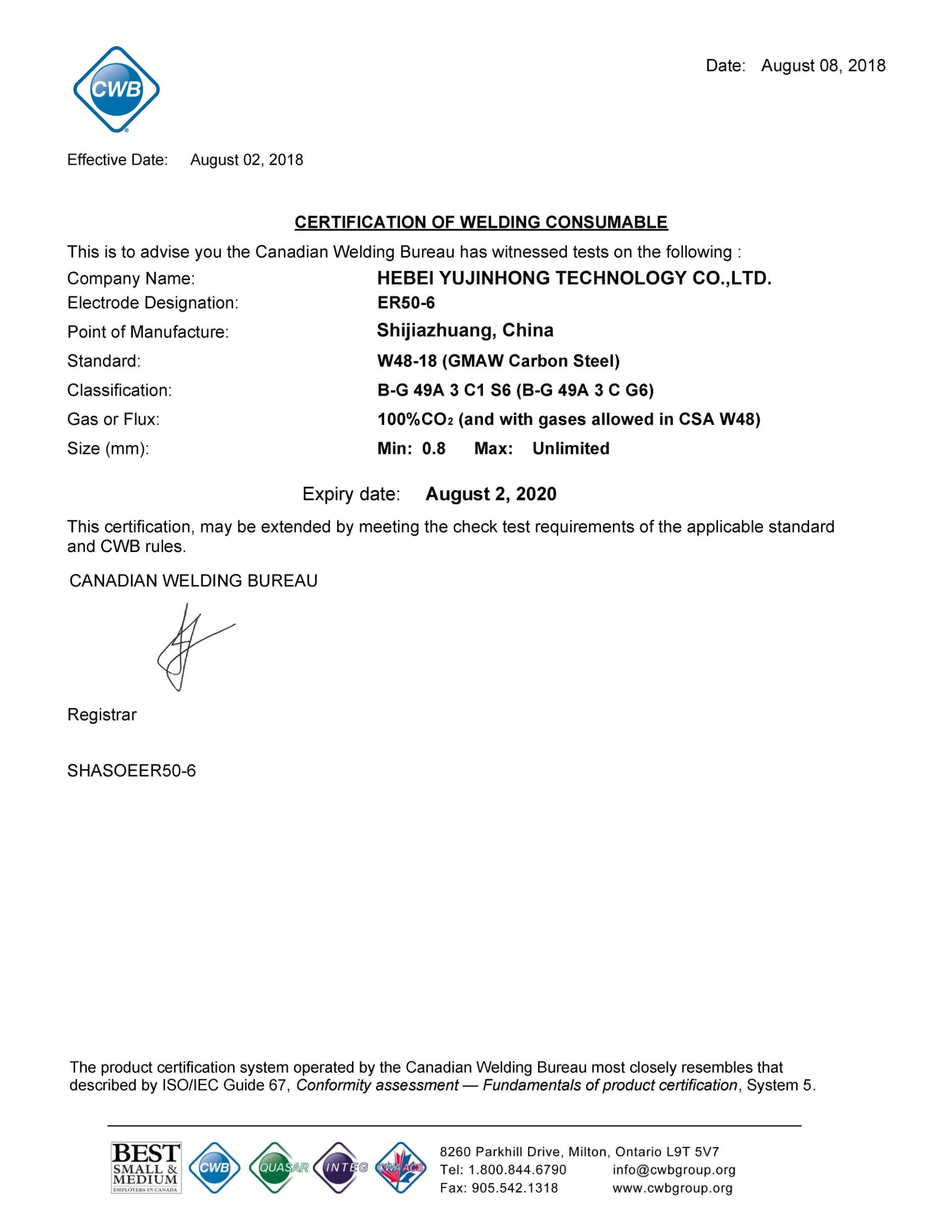

Many Chinese factories follow international quality certifications, such as ISO 9001, to assure customers of the reliability of their products. This focus on quality has helped cement China's reputation as a leading supplier of welding electrodes globally. Factors such as local availability of raw materials and labor costs also contribute positively to the competitiveness of Chinese manufacturers.

Technological Advancements

china electrodos 3/32 6013 factories

In recent years, technological innovations have played a pivotal role in enhancing the manufacturing processes of 3/32 electrodes in China. Automation and robotics are increasingly finding their way into the production line, leading to improved precision and reduced labor costs. Additionally, research and development initiatives are focused on developing new types of coatings that increase the performance and durability of electrodes under various welding conditions.

Moreover, environmentally friendly manufacturing practices are being adopted, reducing the carbon footprint associated with production. These advancements not only improve the quality of the electrodes but also position Chinese factories as responsible players in the global market.

Market Trends

The global demand for welding electrodes, particularly the 3/32-inch variety, is influenced by several market dynamics. Increasing infrastructure development in emerging economies, growth in the automotive industry, and a shift toward renewable energy sources are driving factors for the welding market. As manufacturers seek reliable and high-quality electrodes, the demand for Chinese products continues to grow.

Export markets are particularly lucrative for Chinese manufacturers, who benefit from established trade relationships and competitive pricing. However, they face competition from manufacturers in countries such as South Korea, Japan, and the United States, who also produce high-quality welding electrodes. To maintain their edge, Chinese factories must continuously innovate and adapt to changing market demands.

Conclusion

The manufacturing of 3/32-inch electrodes in China showcases the country's prowess in the industrial sector. With a focus on quality, technological advancement, and responsiveness to global market trends, Chinese manufacturers are well-positioned to meet the growing demands of the welding industry. As the landscape evolves, collaboration with international partners and adherence to global standards will further enhance the competitiveness of China's electrode manufacturing sector. As a result, the future looks promising for this vital segment of the economy, contributing significantly to both domestic employment and global exports.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025