Jun . 15, 2024 18:50

Back to list

China's leading CO2 welding wire factories.

The Evolution of CO2 Welding Wires in China

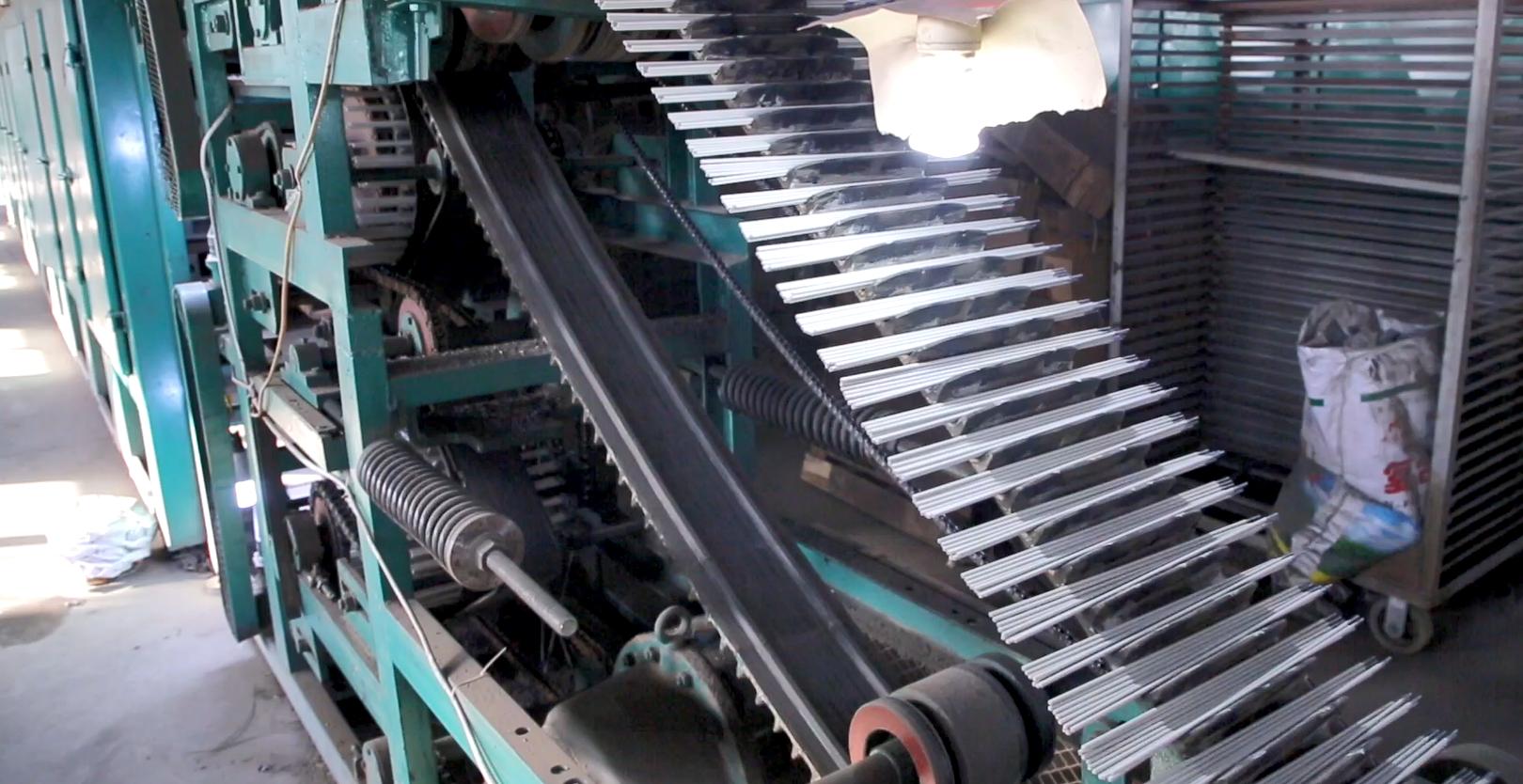

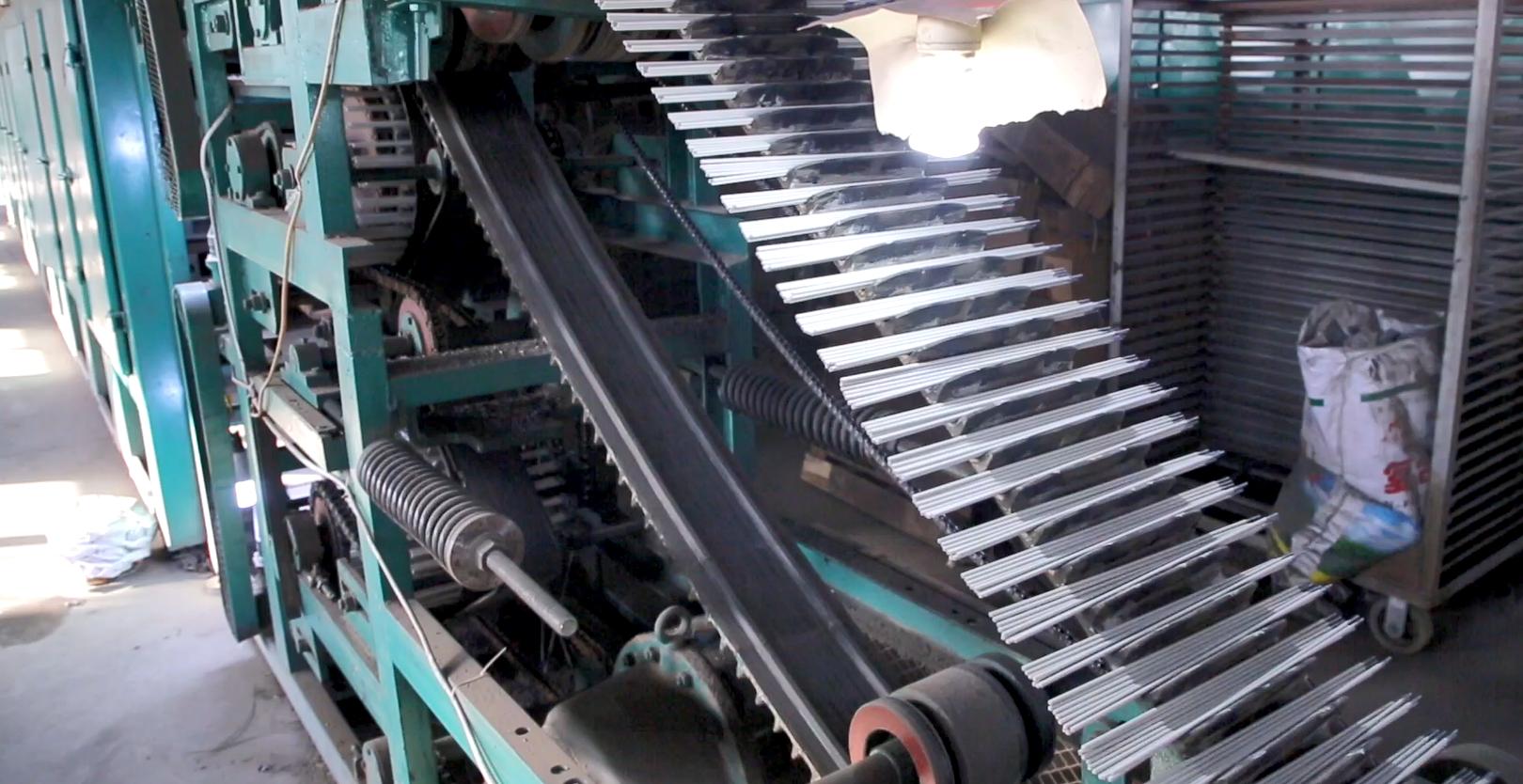

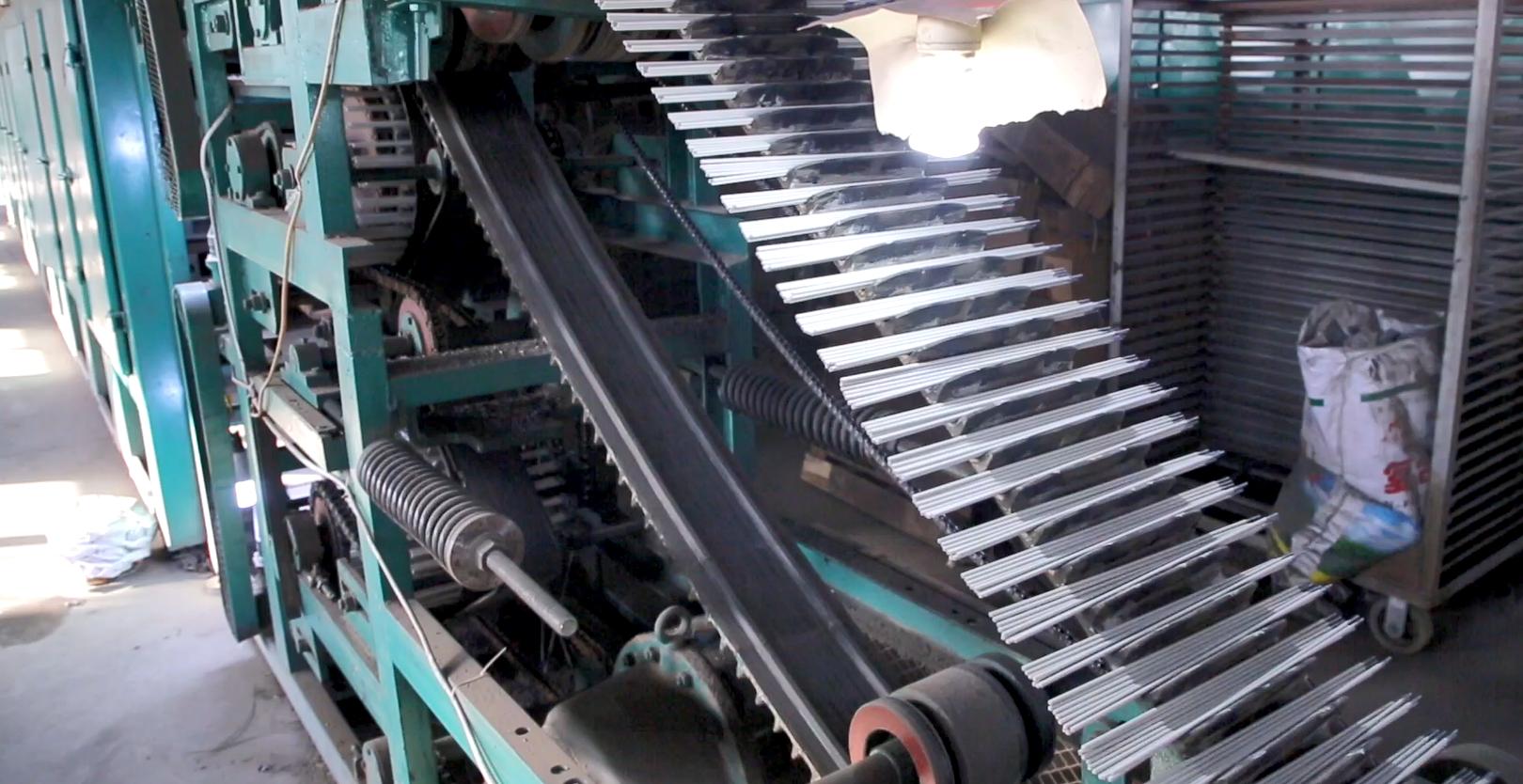

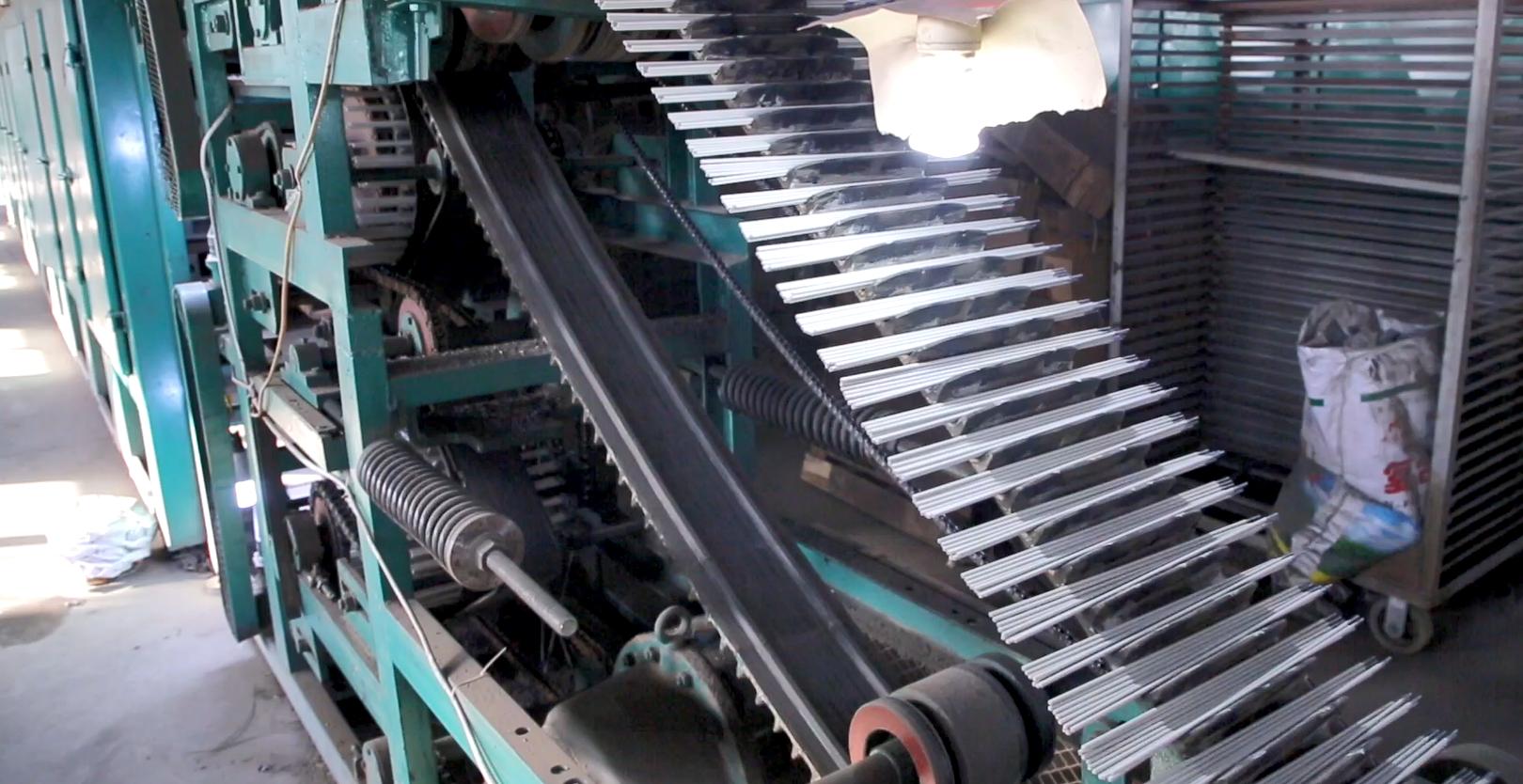

In the vast and rapidly industrializing landscape of China, the production of carbon dioxide (CO2) welding wires has become a critical aspect of manufacturing and construction. These wires, essential for gas metal arc welding (GMAW) processes, have seen significant advancements in their factories, leading to improvements in efficiency and quality.

The journey of CO2 welding wires in China began with the establishment of specialized factories that focused on producing high-quality wires for various industrial needs. Over the years, these factories have adopted cutting-edge technology and innovative techniques to enhance the production process. From automated machinery to advanced quality control systems, every aspect of wire manufacturing has been optimized for precision and performance.

One notable development is the shift towards eco-friendliness in production methods. As environmental concerns grow globally, Chinese manufacturers are increasingly implementing sustainable practices to minimize their ecological footprint. This includes using recycled materials where possible and reducing energy consumption during the production process.

Moreover, the demand for CO2 welding wires has spurred intense competition among manufacturers. To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability

To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability china mig co2 welding wires factories. This relentless pursuit of innovation not only benefits the domestic market but also positions China as a major player in the global welding supplies industry.

Another key area of focus has been the expansion into international markets. Recognizing the potential for global reach, many Chinese CO2 welding wire factories have sought certifications that comply with international standards. By ensuring their products meet the rigorous requirements of foreign markets, they have successfully penetrated new territories and established a strong presence in countries worldwide.

In conclusion, the evolution of CO2 welding wires in China mirrors the country's broader industrial progress. With a commitment to innovation, sustainability, and global integration, Chinese factories continue to shape the future of welding materials on an international scale. As technology advances and global demands evolve, it will be exciting to witness how these factories adapt and contribute to the ever-changing landscape of manufacturing and construction.

china mig co2 welding wires factories. This relentless pursuit of innovation not only benefits the domestic market but also positions China as a major player in the global welding supplies industry.

Another key area of focus has been the expansion into international markets. Recognizing the potential for global reach, many Chinese CO2 welding wire factories have sought certifications that comply with international standards. By ensuring their products meet the rigorous requirements of foreign markets, they have successfully penetrated new territories and established a strong presence in countries worldwide.

In conclusion, the evolution of CO2 welding wires in China mirrors the country's broader industrial progress. With a commitment to innovation, sustainability, and global integration, Chinese factories continue to shape the future of welding materials on an international scale. As technology advances and global demands evolve, it will be exciting to witness how these factories adapt and contribute to the ever-changing landscape of manufacturing and construction.

To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability

To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability To stay ahead, factories are continuously researching and developing new alloy compositions and coating technologies that offer superior welding performance and durability china mig co2 welding wires factories. This relentless pursuit of innovation not only benefits the domestic market but also positions China as a major player in the global welding supplies industry.

Another key area of focus has been the expansion into international markets. Recognizing the potential for global reach, many Chinese CO2 welding wire factories have sought certifications that comply with international standards. By ensuring their products meet the rigorous requirements of foreign markets, they have successfully penetrated new territories and established a strong presence in countries worldwide.

In conclusion, the evolution of CO2 welding wires in China mirrors the country's broader industrial progress. With a commitment to innovation, sustainability, and global integration, Chinese factories continue to shape the future of welding materials on an international scale. As technology advances and global demands evolve, it will be exciting to witness how these factories adapt and contribute to the ever-changing landscape of manufacturing and construction.

china mig co2 welding wires factories. This relentless pursuit of innovation not only benefits the domestic market but also positions China as a major player in the global welding supplies industry.

Another key area of focus has been the expansion into international markets. Recognizing the potential for global reach, many Chinese CO2 welding wire factories have sought certifications that comply with international standards. By ensuring their products meet the rigorous requirements of foreign markets, they have successfully penetrated new territories and established a strong presence in countries worldwide.

In conclusion, the evolution of CO2 welding wires in China mirrors the country's broader industrial progress. With a commitment to innovation, sustainability, and global integration, Chinese factories continue to shape the future of welding materials on an international scale. As technology advances and global demands evolve, it will be exciting to witness how these factories adapt and contribute to the ever-changing landscape of manufacturing and construction. Previous:

Latest news

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025