China's Leading Factory for High-Quality CO2 Welding Wire Production and Supply Solutions

The Growth of China's CO2 Welding Wire Industry

In recent years, the demand for CO2 welding wire has surged globally, and China has emerged as one of the leading producers of this essential welding material. CO2 welding, which predominantly uses carbon dioxide as a shielding gas, is particularly popular due to its efficiency in producing high-quality welds across various applications. This has led to a significant increase in the establishment and growth of CO2 welding wire factories throughout China.

The Manufacturing Process

The manufacturing process of CO2 welding wire involves several stages, starting from raw materials like low-carbon steel. Factories in China utilize advanced technologies and automated systems to enhance production efficiency. This includes wire drawing, annealing, and coating processes to ensure the final product meets the required specifications. Quality control is paramount, with strict testing protocols in place to ensure that the welding wire adheres to domestic and international standards.

Key Features of Chinese CO2 Welding Wire

Chinese CO2 welding wires are known for their excellent tensile strength, low splatter, and smooth bead appearance. Factories invest heavily in research and development to improve the performance of their products. By employing advanced alloying techniques and enhancements in the production process, manufacturers are able to produce welding wires that can be effectively used in diverse applications, from automotive to construction industries.

Environmental Considerations

As the world becomes increasingly aware of the impact of industrial processes on the environment, Chinese CO2 welding wire factories are adopting greener practices. Efforts are being made to reduce carbon emissions and minimize waste. The use of recycled materials in the production of welding wire is also gaining traction, aligning with global sustainability goals. Factories are implementing cleaner technologies to ensure that they meet both local and international environmental standards.

china co2 welding wire factory

Market Demand and Exports

The rising global demand for CO2 welding wire has positioned China as a key player in the international market. The country's factories not only supply the domestic market but also export significant quantities to countries around the world. Factors contributing to this growth include competitive pricing, high-quality products, and the ability to scale production rapidly. Chinese manufacturers are also actively participating in international trade fairs, showcasing their products to potential clients and establishing trade relationships.

Challenges in the Industry

Despite the booming market, the CO2 welding wire industry in China faces several challenges. Competition is fierce, both from domestic rivalries and foreign manufacturers. Additionally, fluctuations in raw material prices can impact production costs. Factories must continually innovate and improve efficiencies to maintain their competitive edge in the market. The need for skilled labor is also crucial, as the industry requires workers who are knowledgeable about advanced manufacturing technologies and quality control processes.

Future Prospects

Looking ahead, the future of China's CO2 welding wire industry appears promising. With ongoing investments in technology and a commitment to sustainability, factories are likely to enhance their production capabilities and product offerings. The increasing emphasis on automation and smart manufacturing will further bolster the industry’s growth. As industries globally demand more efficient and environmentally-friendly solutions, the role of Chinese CO2 welding wire manufacturers will undoubtedly expand.

In conclusion, the flourishing CO2 welding wire factories in China symbolize the country's manufacturing prowess and adaptability in a rapidly evolving market. As the industry addresses challenges and leverages new opportunities, it is set to remain a critical component of global welding solutions for years to come.

-

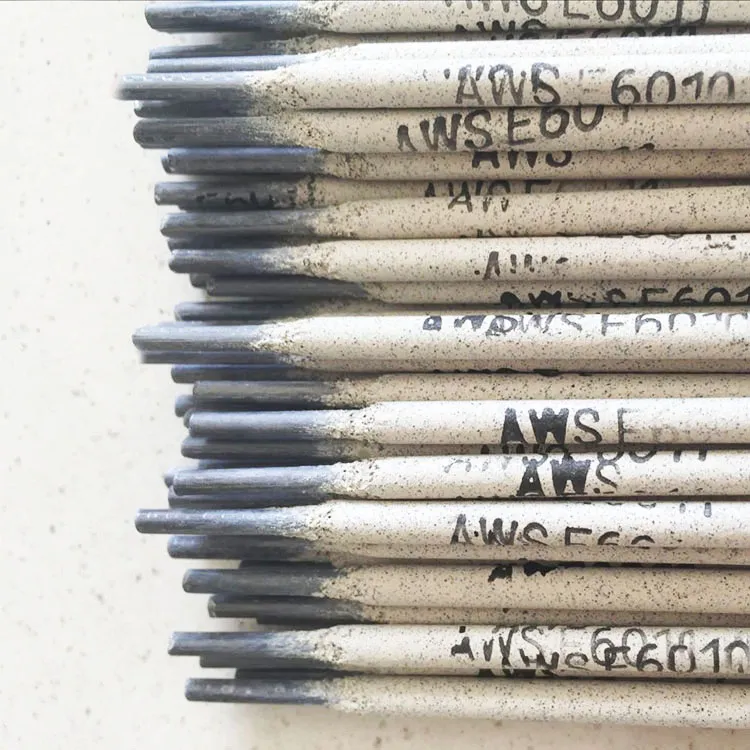

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025