China's Leading Manufacturer of High-Quality Welding Electrodes for Various Industrial Applications

China 6013 Welding Electrode Factory Pioneering Quality and Innovation in Welding

China has long been recognized as a global leader in manufacturing, and one of its standout products is the 6013 welding electrode. These electrodes are essential for various welding processes, especially in the construction and fabrication industries. This article explores the significance of 6013 welding electrodes, the manufacturing processes involved in their production, and the factories that specialize in their creation.

Understanding 6013 Welding Electrodes

The 6013 welding electrode is a type of mild steel electrode known for its versatility and ease of use. It is often utilized in both flat and horizontal welding positions, making it a popular choice among welders for a wide range of applications, including the construction of light structural work, automotive repair, and machinery manufacturing. The designation “6013” signifies specific properties the first two digits indicate the minimum yield strength (in thousands of pounds per square inch), while the last digit describes the welding position and type of coating.

The 6013 electrode is recognized for its excellent arc stability, smooth operation, and low spatter production. It is coated with a mixture of cellulose and mineral compounds, which contribute to a stable arc when welding. This makes it an excellent choice for both professional and amateur welders, as its forgiving nature allows for easier manipulation and superior results.

The Manufacturing Process

The production of 6013 welding electrodes involves several critical steps, all aimed at ensuring the highest quality and performance. The first stage is the selection of raw materials, which typically includes steel wire and various coating substances. The choice of materials directly affects the electrode’s performance characteristics, such as its arc stability and penetration.

china 6013 welding electrode factory

Once the materials are selected, the next step involves the drawing process, where steel wires are drawn to specific diameters suitable for welding applications. Following this, the coating is applied in a carefully controlled environment to ensure uniformity and adherence. The coating application process can involve various techniques, including extrusion or spraying, followed by drying at precise temperatures to set the coating properly.

After coating, the electrodes undergo quality control inspections to ensure they meet industry standards and specifications. Tests may include evaluations of arc stability, tensile strength, and even visual inspections for any surface imperfections. Manufacturing facilities in China often utilize advanced technologies and automated processes to enhance efficiency and consistency in production.

Leading Factories in China

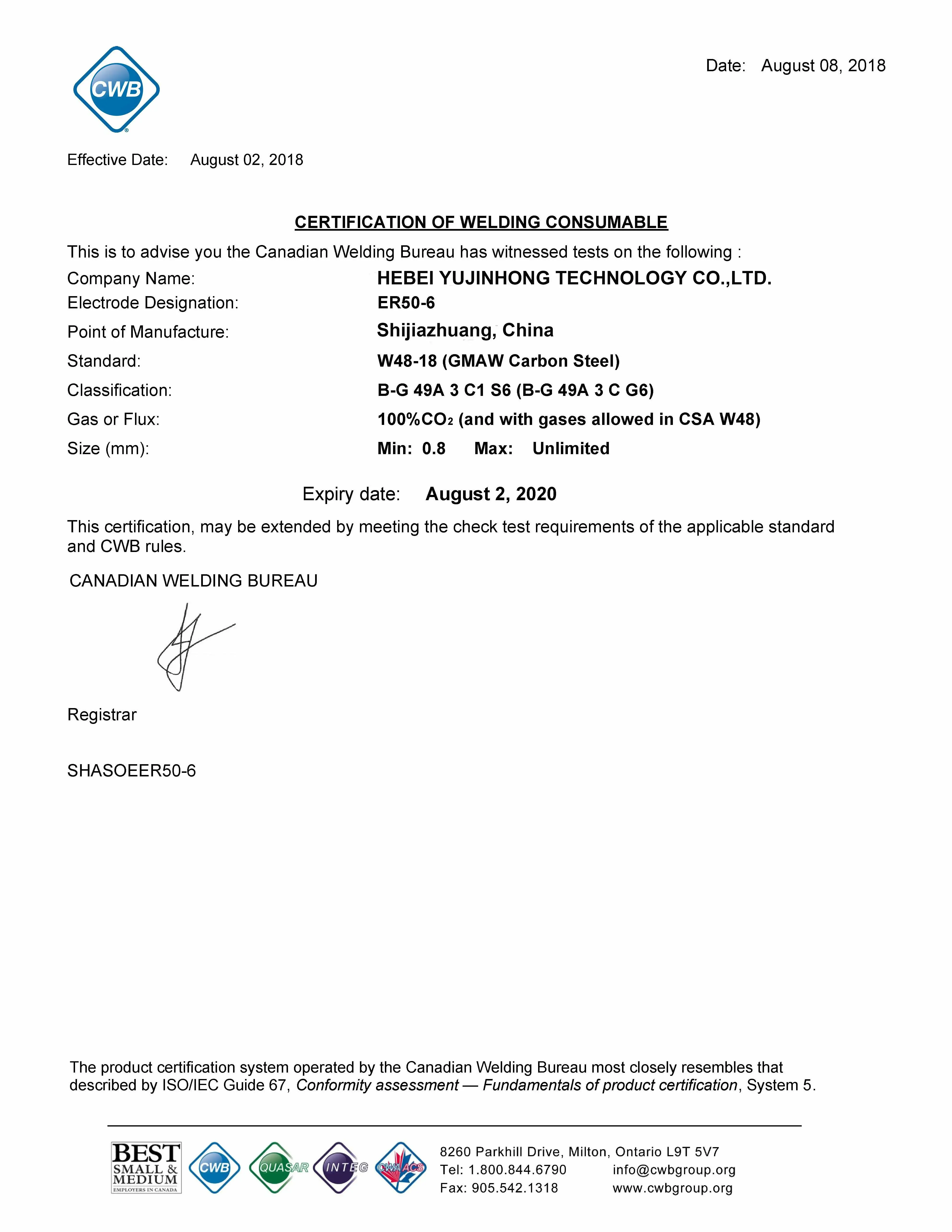

Several factories in China specialize in the production of 6013 welding electrodes, investing in high-tech machinery and skilled labor to uphold quality standards. These facilities often adhere to international certifications, assuring users that their products comply with global quality benchmarks. The commitment to innovation and quality makes China's welding electrode factories key players in the global market.

Moreover, the competitive pricing of products manufactured in China has allowed them to penetrate international markets effectively. Many factories export their 6013 welding electrodes to countries around the world, contributing to numerous construction and manufacturing projects.

Conclusion

In conclusion, the 6013 welding electrode plays a vital role in various applications across industries. With China positioned as a leading manufacturer of these electrodes, its factories have become synonymous with quality and innovation, making them a sought-after source for welders everywhere. As technology continues to advance, one can anticipate even greater developments in electrode manufacturing, ensuring that welders have access to the best tools for their craft. China's commitment to producing top-quality 6013 welding electrodes solidifies its reputation on the global stage as a manufacturing powerhouse.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025