china s.s.welding wire supplier

The Rise of Chinese Stainless Steel Welding Wire Suppliers

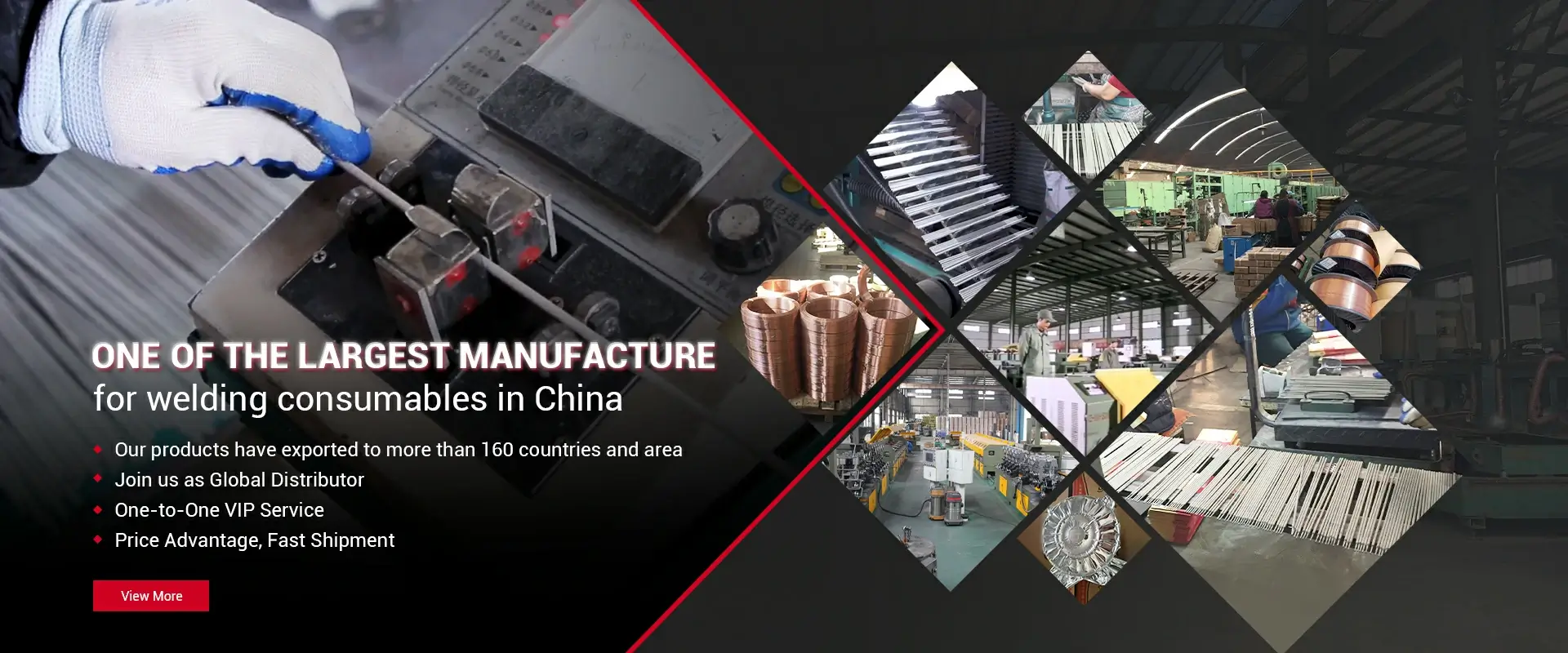

In recent years, China has established itself as a prominent player in the global market for stainless steel welding wire. As industries worldwide continue to expand, the demand for high-quality welding materials has surged, leading to a corresponding increase in the prominence of Chinese suppliers. This article will explore the reasons behind China's significant rise in this sector, the advantages of sourcing stainless steel welding wire from Chinese manufacturers, and the challenges they face in the competitive global market.

Rapid Development and Competitiveness

China's stainless steel welding wire industry has benefited from the country's rapid industrialization and technological advancements. With a solid foundation in metallurgy and manufacturing, Chinese suppliers have invested heavily in machinery and technology to produce high-quality welding wire. They are capable of producing a wide range of wire types, including solid wire, flux-cored wire, and metal-cored wire, to meet the diverse needs of various industries such as construction, automotive, aerospace, and energy.

Moreover, the combination of an extensive labor pool and competitive manufacturing costs allows Chinese suppliers to offer products at more attractive price points compared to their counterparts in other countries. This price advantage has played a crucial role in capturing the attention of international customers who are seeking cost-effective solutions without compromising on quality.

Quality and Standards

While affordability is a significant factor, quality is paramount in the welding industry. Chinese stainless steel welding wire manufacturers have recognized this need and have taken substantial steps to improve the quality of their products. Many suppliers adhere to international standards such as ISO 9001 and AWS (American Welding Society) certification, ensuring that their products meet stringent quality requirements. This commitment to quality has enabled Chinese producers to gain the trust of international clients who prioritize reliability and performance in their welding operations.

Additionally, the Chinese government has implemented various regulatory frameworks to oversee the industry, further emphasizing quality control and environmental sustainability. As a result, many Chinese manufacturers now offer environmentally friendly products that comply with global green standards, giving them an edge in markets that prioritize sustainable practices.

china s.s.welding wire supplier

The Global Market Dynamics

As the global economy continues to evolve, the demand for stainless steel welding wire is set to rise. Emerging economies are rapidly industrializing, and their growing manufacturing sectors require reliable welding solutions. Chinese suppliers are well-positioned to capitalize on this trend by expanding their export markets. Countries in Southeast Asia, Africa, and Latin America represent significant opportunities for Chinese manufacturers to explore, along with established markets in Europe and North America.

Furthermore, the ongoing trade disputes and geopolitical tensions have led many companies to reconsider their supply chains. Chinese suppliers, with their established manufacturing capabilities, can provide a reliable alternative source for welding materials, contributing to the diversification of global supply chains.

Challenges Ahead

Despite their many advantages, Chinese stainless steel welding wire suppliers face challenges in the global marketplace. Increased competition from manufacturers in other regions, particularly those in Southeast Asia and Eastern Europe, is intensifying. Additionally, concerns over product quality and intellectual property rights continue to create barriers for some potential customers.

Moreover, geopolitical tensions and trade policies can impact exports, leading to uncertainties in pricing and availability. For Chinese suppliers, navigating these challenges requires strategic approaches, including investing in innovation, enhancing quality assurance processes, and building strong relationships with customers across the globe.

Conclusion

In summary, Chinese stainless steel welding wire suppliers have emerged as key players in the global market, benefiting from competitive pricing, a commitment to quality, and a strong manufacturing base. While they face challenges in an increasingly competitive landscape, their potential for growth remains significant as worldwide demand for quality welding solutions continues to rise. As long as these suppliers continue to focus on quality, innovation, and responsive customer service, they are well-positioned to thrive in the global market for years to come.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025