china vertical stick welding 7018 factory

Understanding the China Vertical Stick Welding Industry A Focus on 7018 Electrodes

When discussing welding technologies, the significance of stick welding, particularly with 7018 electrodes, cannot be overstated. Among various welding techniques, stick welding is widely appreciated for its simplicity, effectiveness, and versatility. In China, the manufacturing of vertical stick welding equipment and materials like the 7018 electrode has garnered considerable attention due to the substantial industrial growth and the increasing demand for high-quality welding solutions.

The Basics of Stick Welding

Stick welding, formally known as Shielded Metal Arc Welding (SMAW), is one of the oldest and most widely used welding processes. It involves the use of a consumable electrode coated in flux to join metal components. When the electrode is melted, the flux coating produces a shield of gas that protects the weld from atmospheric contaminants, leading to strong and durable joints. The key to successful stick welding lies in selecting the appropriate electrode for the job, and that’s where the 7018 electrode comes into play.

The 7018 Electrode

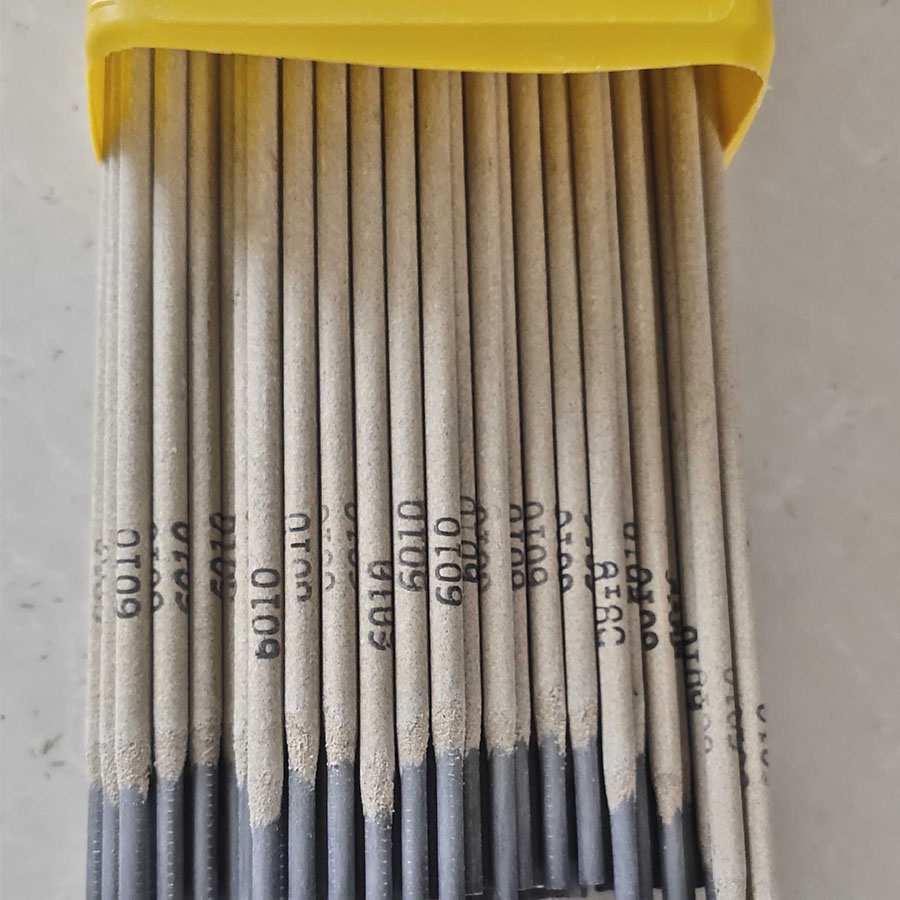

The 7018 electrode is a low-hydrogen, iron powder electrode that is known for producing high-quality welds. It is favored for its crack resistance and overall strength, making it ideal for welding structural steel and other critical applications. The numbers in the designation '7018' indicate the electrode's properties the '70' refers to the minimum yield strength of 70,000 psi, the '1' denotes the welding position (all positions), and the '8' signifies that it contains iron powder and a low-hydrogen flux.

The popularity of the 7018 electrode in China can be attributed to the country's extensive industrial framework, which encompasses construction, manufacturing, and infrastructure development. The demand for robust and reliable welding solutions in these sectors has led to an increased production of 7018 electrodes.

China’s Vertical Stick Welding Equipment

The production process for vertical stick welding equipment is complex and requires a sophisticated understanding of both manufacturing and engineering principles. Numerous factories in China specialize in producing not just the 7018 electrodes but also the welding machines and accessories that are essential for effective stick welding. These factories utilize advanced technology and quality control measures to ensure that their products meet international standards.

china vertical stick welding 7018 factory

Vertical stick welding, specifically, offers unique advantages, especially in construction and fabrication scenarios where working in tight spaces is necessary. The ability to perform vertical welds with precision can significantly enhance productivity and quality. Manufacturers invest in training programs for workers to ensure that they are skilled in these specialized techniques, resulting in a highly competent workforce.

Quality Assurance

China’s factories producing 7018 electrodes are increasingly adopting stringent quality assurance practices. This involves rigorous testing of raw materials and finished products to ensure they meet specific standards. The importance of quality in the welding process cannot be understated, as weld integrity is critical to the safety and longevity of welded structures.

Many Chinese manufacturers are also seeking international certifications, such as ISO 9001, to enhance their credibility in the global market. This push for quality not only helps them compete internationally but also ensures that end-users receive reliable products that meet their specific welding needs.

The Future of Stick Welding in China

As China continues to advance its manufacturing technologies and expand its infrastructure projects, the demand for vertical stick welding and 7018 electrodes is expected to grow. Industry trends indicate a shift towards more automation and the use of advanced materials, which may lead to innovations in the welding process itself.

In addition, the global push for sustainable practices and materials may influence the future development of welding electrodes, including the 7018. Manufacturers are likely to invest in research and development to create more efficient, eco-friendly welding solutions.

Conclusion

The vertical stick welding industry in China, particularly the production of 7018 electrodes, plays a vital role in the country’s rapidly evolving manufacturing landscape. With increasing quality control measures and a focus on advanced technologies, Chinese manufacturers are well-positioned to meet both domestic and international demands. As industries continue to grow and evolve, the importance of effective welding solutions, including the versatility and reliability of 7018 electrodes, will remain prominent in China’s industrial future.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025