China Welding Electrode 6013 Manufacturers and Suppliers for Quality Welding Solutions

Understanding China Welding 6013 Electrode Manufacturers

Welding is a vital process in various industries, including construction, manufacturing, and automotive. Among the numerous welding electrodes available, the E6013 is one of the most widely used types due to its versatility and effectiveness. China, as a leading manufacturer of welding electrodes, plays a crucial role in supplying E6013 electrodes to the global market. This article explores the characteristics, advantages, and the manufacturing landscape of China’s E6013 welding electrodes.

Characteristics of E6013 Welding Electrodes

E6013 electrodes are classified as rutile-coated electrodes, which makes them suitable for welding in both alternating and direct current modes. They are primarily designed for mild steel and can handle a variety of welding applications, including sheet metal work and structural welding. The designation “E6013” indicates several characteristics “E” stands for electrode, “60” represents the minimum tensile strength of 60,000 psi, and “1” denotes all-position welding capability, while “3” suggests a medium penetration level.

One of the key characteristics of E6013 electrodes is their ease of use. The electrodes produce a stable arc and generate less spatter, resulting in cleaner welds which require less post-weld cleaning. Additionally, these electrodes have good arc stability, making them ideal for both experienced welders and beginners alike.

Advantages of Using E6013 Electrodes

The advantages of E6013 electrodes contribute to their popularity in various industries. One primary advantage is their versatility; they can be used on both thin and thick materials, making them suitable for a diverse range of applications. Furthermore, the welds created with E6013 electrodes exhibit strong mechanical properties, ensuring that the welded joints are durable and reliable under various conditions.

E6013 electrodes are also known for their favorable welding characteristics, such as the ability to produce a smooth, aesthetically pleasing bead. This quality is particularly important in applications where the appearance of the weld is crucial. The electrodes work well in various positions, including flat, horizontal, vertical, and overhead, enhancing their practicality for different welding scenarios.

The Manufacturing Landscape in China

china welding 6013 electrode manufacturers

China is home to a large number of welding electrode manufacturers, with significant expertise in producing E6013 electrodes. The country’s manufacturing sector benefits from advanced technology, skilled labor, and economies of scale, allowing for the production of high-quality electrodes at competitive prices.

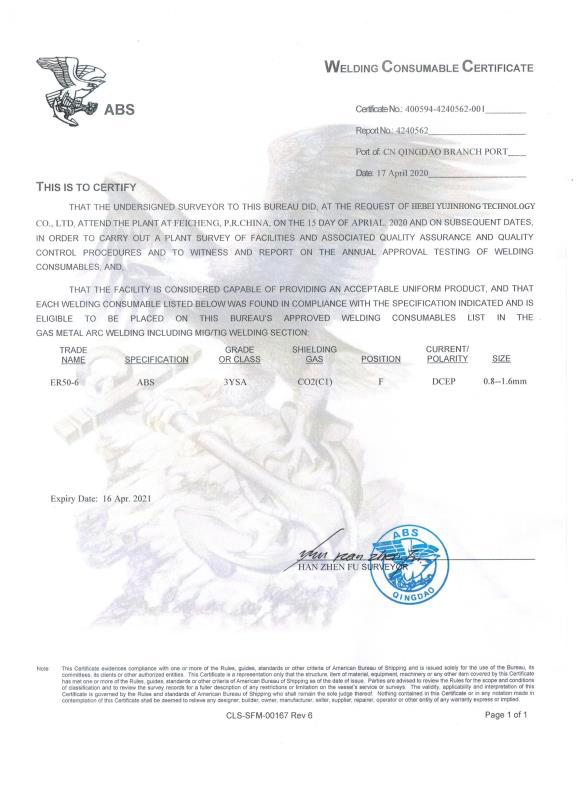

Chinese manufacturers employ rigorous quality control measures throughout the production process to ensure that their electrodes meet international standards. Many manufacturers adhere to certifications such as ISO 9001, which guarantees that they implement consistent quality management systems. This commitment to quality not only enhances the reputation of Chinese welding electrodes but also builds trust with customers around the world.

In addition to traditional manufacturing practices, Chinese companies are increasingly investing in research and development to innovate their products. This includes developing new electrode formulations and improving the coatings to enhance performance, usability, and environmental sustainability.

Export Market and Global Reach

Chinese manufacturers have established a strong presence in the global welding electrode market, exporting E6013 electrodes to various regions, including North America, Europe, and Asia. The affordable pricing and reliable quality of these electrodes have made them a preferred choice for many international buyers. Additionally, the growing demand for welding applications in emerging markets further supports the expansion of Chinese welding product exports.

The trade relationships developed over the years also contribute to the ongoing success of Chinese E6013 electrode manufacturers. By participating in international trade fairs and welding exhibitions, these companies showcase their products and foster connections with potential buyers worldwide.

Conclusion

In conclusion, China’s E6013 welding electrode manufacturers are integral players in the global welding industry. With their focus on quality, innovation, and customer satisfaction, these manufacturers not only provide reliable and versatile products but also significantly contribute to advancements in welding technology. As industries continue to evolve, the demand for E6013 electrodes from Chinese manufacturers is likely to grow, further solidifying China’s role in the international welding market.

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025