china welding electrode 2.5mm manufacturers

Exploring the Landscape of China’s 2.5mm Welding Electrode Manufacturers

The welding industry is a cornerstone of manufacturing and construction sectors worldwide. Among the critical materials used in welding processes, welding electrodes play an essential role, particularly the 2.5mm variants. This article delves into the landscape of China’s 2.5mm welding electrode manufacturers, highlighting the significance of these products, the manufacturing process, key players in the industry, and the prospects for future development.

Importance of 2.5mm Welding Electrodes

Welding electrodes come in various sizes, with 2.5mm being one of the most commonly used diameters. This size is particularly favored for its versatility in applications such as steel fabrication, shipbuilding, construction, and repair work. The 2.5mm electrodes can easily penetrate and bond thinner materials or even medium-thickness steel, making them a vital component in a welder's toolkit. Their ability to provide quality welds, ease of use, and adaptability to different welding processes, including MIG and TIG, establishes their importance in the spot-welding techniques commonly employed in diverse industries.

Manufacturing Process

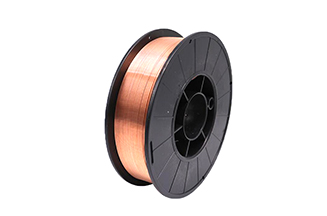

The production of welding electrodes involves several steps that require precision and the use of advanced technology. Key components in the manufacturing process include the choice of raw materials, which generally consist of high-quality steel wires and a coating material that facilitates a stable arc and superior weld quality. The manufacturing process can typically be divided into the following stages

1. Wire Drawing This involves the reduction of the diameter of the steel wire to achieve the desired thickness, commonly 2.5mm. 2. Coating Once the wire is prepared, a mixture of flux is applied to provide protection during the welding process by preventing oxidation and contamination.

3. Drying The coated electrodes are dried to ensure the coating adheres properly and performs effectively during welding.

China's manufacturing facilities often utilize state-of-the-art technology that automates many of these processes, thus enhancing production efficiency, reducing waste, and ensuring uniform quality across batches.

china welding electrode 2.5mm manufacturers

Key Players in the Industry

The Chinese market is home to numerous manufacturers specializing in welding electrodes. Some of the most prominent companies include

- China National Petroleum Corporation (CNPC) Known for its vast range of industrial products, CNPC also produces high-quality welding electrodes suitable for various applications. - Shandong Jinshun Welding Material Co., Ltd This company focuses on producing electrodes that meet international standards, emphasizing quality and reliability in different industrial sectors.

- Jiangsu Zhongtian Welding Materials Co., Ltd A key player renowned for its advanced manufacturing techniques and commitment to research and development, offering innovative welding solutions.

These companies are not only well-established within China but are also actively exporting their products to international markets, reflecting the global demand for high-quality 2.5mm welding electrodes.

Future Development Prospects

As industries grow and evolve, the demand for quality welding materials continues to rise. In particular, the increased focus on environmentally friendly practices aims to stimulate innovation within the manufacturing processes. Chinese manufacturers are increasingly adopting sustainable production methods, integrating technology such as automation, and focusing on waste reduction. Furthermore, the trend toward digitalization in manufacturing processes promises to enhance efficiency and product quality.

Additionally, as global construction and manufacturing sectors recover and expand in the post-COVID landscape, the demand for welding electrodes is expected to rise significantly. Companies that can adapt to changing market dynamics and embrace technological advancements will likely thrive in this competitive industry.

Conclusion

China's 2.5mm welding electrode manufacturers serve a crucial role in fulfilling the requirements of modern industries. With a robust manufacturing framework, several key players, and a focus on innovation and sustainability, the industry is well-positioned for future growth. The continuous improvement of welding electrode quality and performance will not only support China's booming manufacturing sector but will also bolster its reputation as a global leader in welding materials. The future looks promising as manufacturers adapt to meet evolving market demands and contribute to the sustainability of welding practices worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025