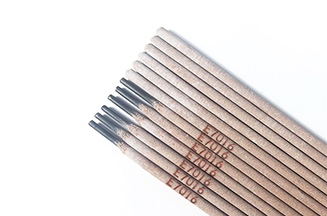

E6011 Welding Electrodes Manufacturers and Suppliers in China

Understanding China’s Welding Electrode E6011 Factories

Welding is a critical process in various industries, including construction, automotive, and manufacturing. One of the essential components in the welding process is the electrode, which conducts electric current to create a weld. Among the diverse range of welding electrodes available, the E6011 electrode is widely recognized for its versatility and efficiency. In recent years, China has emerged as a significant player in the production and supply of E6011 welding electrodes, establishing numerous factories dedicated to this essential task.

Overview of E6011 Welding Electrodes

The E6011 welding electrode is a type of coated stick electrode primarily used for electrical arc welding of mild steel and low alloy steels. This electrode is appreciated for its ability to produce deep penetration welds even on rusty or dirty surfaces, making it ideal for maintenance and repair work. The E in E6011 stands for electrode, while 60 refers to the minimum tensile strength of the weld (60,000 psi), and 1 indicates that it can be used in all positions. The versatility of E6011 makes it a popular choice among welders globally.

The Rise of Chinese E6011 Factories

China has developed its welding industry significantly over the past few decades. With advancements in technology, increased production capacity, and an expanding workforce, Chinese factories have positioned themselves as leading manufacturers of welding electrodes, including E6011. The growth of E6011 production in China can be attributed to several factors

1. Cost-Effectiveness Chinese factories often offer competitive pricing due to lower labor costs and the ability to mass-produce products. This cost advantage allows businesses worldwide to source E6011 electrodes at a lower rate compared to other markets.

2. Quality Improvements As international standards for welding materials have evolved, many Chinese manufacturers have invested in technology and quality control processes. This proactive approach has helped improve the quality of E6011 electrodes, meeting or even exceeding global standards.

china welding electrode e6011 factories

3. Increasing Demand The global demand for welding consumables has been on the rise, fueled by construction booms in developing countries and the resurgence of manufacturing in regions like North America and Europe. Chinese factories have been quick to capitalize on this demand, enhancing their production capabilities to cater to international markets.

4. Expanding Export Markets Many Chinese welding electrode manufacturers have pursued aggressive export strategies. By participating in international trade shows and online marketplaces, they have connected with customers around the world, further solidifying China's position as a key supplier of E6011 electrodes.

Challenges Faced by Chinese Factories

Despite their success, Chinese E6011 factories do face challenges. For instance, competition from other manufacturing countries can exert pressure on profit margins. Additionally, fluctuating raw material prices can impact production costs, making it essential for manufacturers to remain flexible and adaptable.

Quality assurance is another critical area where Chinese factories must focus. As global standards continue to rise, maintaining high-quality output is crucial to retaining customer trust and satisfaction. Some manufacturers are now seeking certifications from reputable organizations to enhance their credibility on the international stage.

Conclusion

In conclusion, the production of E6011 welding electrodes in China has witnessed significant growth, driven by cost-effectiveness, quality improvements, and rising global demand. Chinese factories have made substantial strides in establishing themselves as key suppliers in the welding industry, contributing to the supply chain for various sectors worldwide. While challenges remain, the ongoing commitment to innovation and quality will be vital for these manufacturers as they strive to maintain their competitive edge in the global market. As the industry evolves, the focus will likely shift towards sustainable practices and enhanced production methods, ensuring that China remains a cornerstone in the welding electrode market for years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025