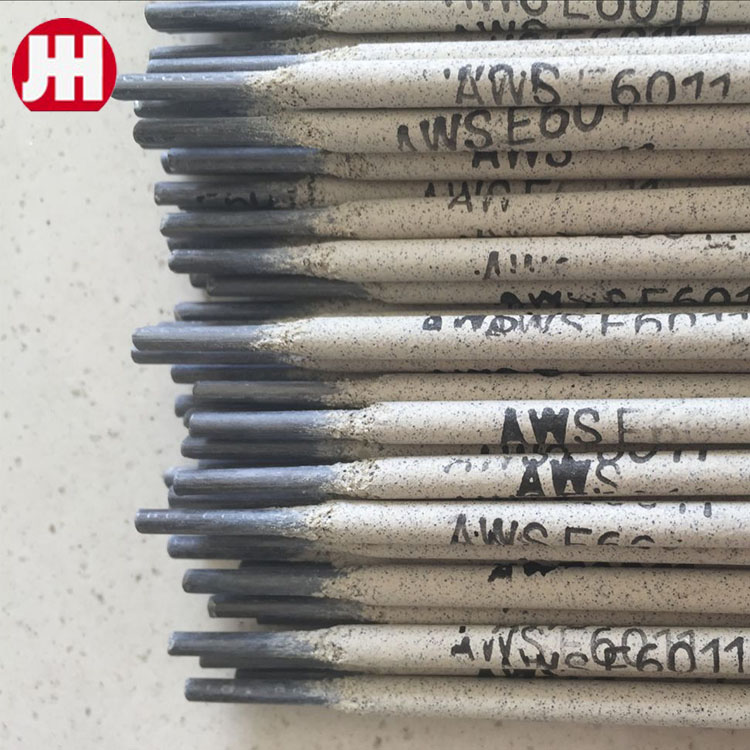

china welding electrode e 6013 factory

Overview of China Welding Electrode E6013 Factory

In the realm of welding, the choice of welding electrodes plays a crucial role in determining the quality and efficiency of the welding process. Among the various types of electrodes available on the market, the E6013 welding electrode stands out due to its versatility and ease of use. This article delves into the manufacturing process, applications, and advantages of E6013 welding electrodes produced in China.

What is E6013 Welding Electrode?

The E6013 electrode is a versatile type of mild steel welding rod characterized by its moderate penetration and excellent arc stability. The 'E' in E6013 signifies that it is an electrode, while the numbers indicate its characteristics. The '60' refers to the tensile strength of the weld metal in thousands of psi, meaning it can withstand up to 60,000 psi. The '1' denotes that it is suitable for all-position welding, and the '3' indicates the type of coating, which is primarily a iron powder coating.

Manufacturing Process

China is home to numerous factories specializing in the production of welding electrodes, including E6013. The manufacturing process involves several key steps

1. Raw Material Selection High-quality steel wire is selected as the core of the electrode. The coating materials, which consist of a mixture of iron powder, cellulose, and mineral compounds, are also meticulously chosen to ensure optimal performance.

2. Wire Drawing The selected steel wire is drawn to the required diameter, typically around 2.5 mm to 4 mm for E6013 electrodes.

3. Coating Application The core wire is then coated with the prepared mixture. This step is crucial, as the coating affects the electrode's arc stability and slag formation during welding.

4. Drying After coating, the electrodes undergo a drying process to remove moisture, which can adversely affect welding quality.

5. Packaging Finally, the electrodes are cut to length, packaged, and prepared for shipment to various markets worldwide.

china welding electrode e 6013 factory

Applications

E6013 welding electrodes are widely used across diverse industries due to their adaptability. Common applications include

- General Fabrication Ideal for repairing and fabricating mild steel structures, machinery, and automotive components. - Sheet Metal Work Perfect for thin sheets, allowing for clean and smooth finish welds. - Construction Utilized in welding applications for constructing buildings, bridges, and other infrastructure projects due to their stable arc and minimal spatter. - Home Improvement Projects Convenient for hobbyists and DIY enthusiasts owing to their ease of use.

Advantages of Chinese E6013 Electrodes

The E6013 electrodes manufactured in China come with several advantages

1. Cost-Effectiveness Chinese factories often produce these electrodes at competitive prices without compromising on quality, making them accessible to a broader market.

2. Consistent Quality Many factories implement stringent quality control measures to ensure that each batch of electrodes meets international standards.

3. Versatility The E6013 electrode is suitable for various positions and material thicknesses, making it a favorite among welders.

4. Easy to Use Its forgiving nature allows for easy handling, making it ideal for both amateur and experienced welders.

Conclusion

China's E6013 welding electrodes are a testament to the country's robust manufacturing capabilities in the welding industry. Their combination of quality, versatility, and cost-effectiveness makes them an excellent choice for a wide range of welding applications. As the demand for efficient and reliable welding solutions continues to grow, the E6013 electrode will undoubtedly play a pivotal role in meeting those needs across the globe.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025