China E7016 Welding Electrode Manufacturers and Their Products Overview

Understanding E7016 Welding Electrodes Insights from China’s Manufacturing Sector

Welding plays an essential role in various industries, and the choice of welding consumables, particularly electrodes, can significantly influence the quality and performance of welds. Among the various types of electrodes available, E7016 welding electrodes have gained considerable attention due to their strength and versatility. This article will explore the characteristics of E7016 electrodes, the manufacturing landscape in China, and the factors influencing the selection of these electrodes in modern welding applications.

What are E7016 Welding Electrodes?

E7016 electrodes are a type of mild steel electrode used for welding applications. The designations of these electrodes conform to the American Welding Society (AWS) specifications. The code 'E' signifies that the product is an electrode, while '70' indicates the minimum yield strength of 70,000 psi. The number '1' denotes a suitable welding position, and '6' refers to the type of coating, which is primarily composed of cellulose and is designed to provide good arc stability and welding characteristics in various positions and environments.

E7016 electrodes are particularly renowned for their high strength and excellent notch impact properties. They are designed for use in both direct current (DC) and alternating current (AC) processes, making them adaptable to diverse welding equipment and conditions. Their ability to produce quality welds even in challenging conditions has made E7016 a preferred choice for critical applications such as construction, shipbuilding, and energy infrastructure.

The Chinese Manufacturing Landscape

China has emerged as a global leader in the manufacturing of welding electrodes, including E7016. With a vast network of factories and suppliers, the country plays a critical role in meeting the growing demand for high-quality welding consumables worldwide. Several factors contribute to China's dominance in this sector

1. Advanced Technology Chinese manufacturers are increasingly adopting advanced technologies and automated production processes. This modernization enhances product quality, ensuring that welding electrodes meet international standards.

2. Cost-Efficiency The relatively lower labor costs in China allow manufacturers to offer competitive prices without compromising on quality. This cost advantage attracts buyers from various parts of the world, enabling China to capture a substantial share of the global market.

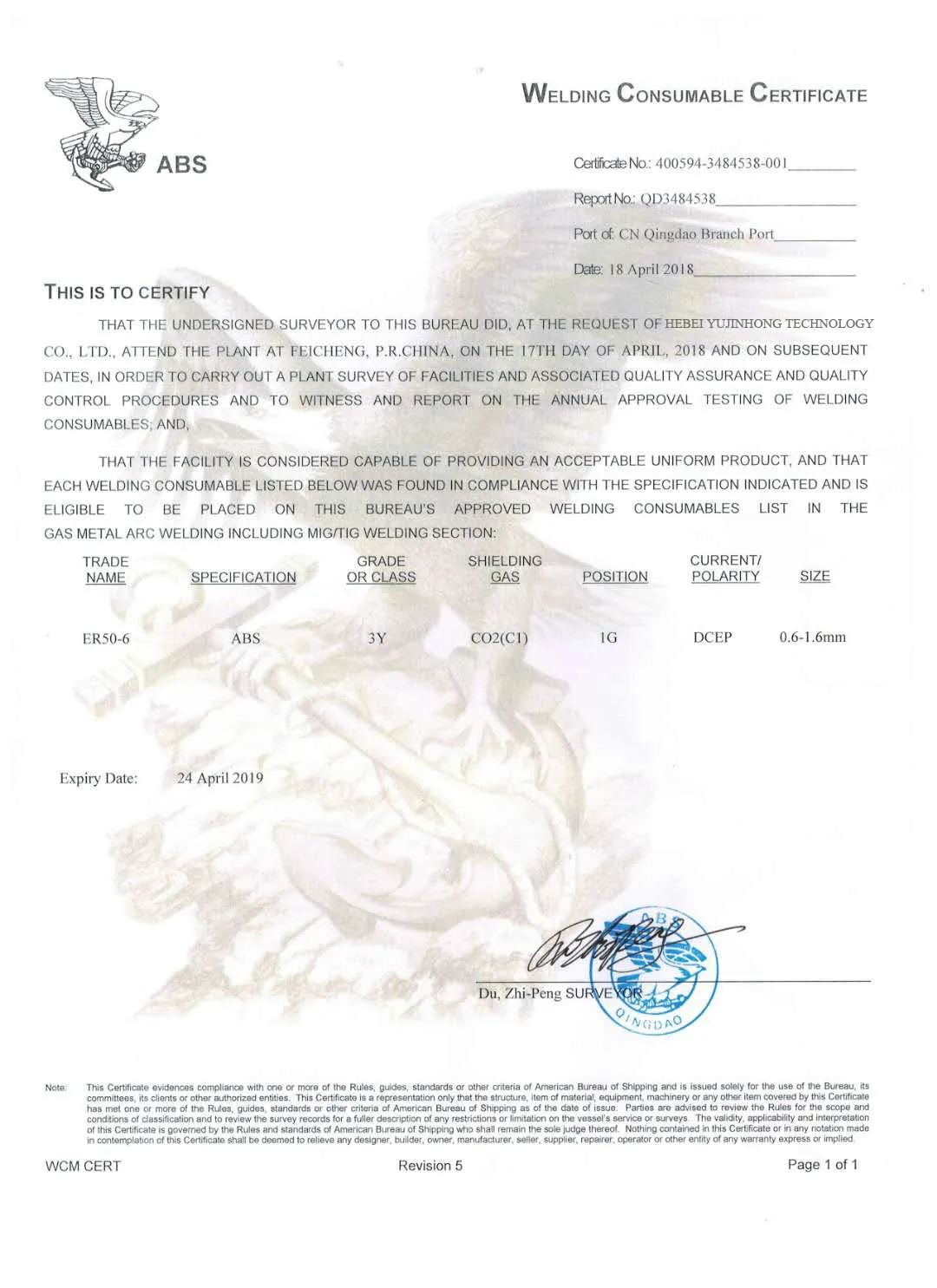

3. Quality Control Many Chinese factories adhere to strict quality control protocols, often acquiring certifications such as ISO 9001. These standards ensure that E7016 electrodes produced in China perform reliably and meet the specifications required by international customers.

china welding electrode e7016 factories

4. Diverse Product Range Chinese manufacturers offer a wide array of E7016 electrodes tailored to different applications. This diversity allows buyers to select the right electrode for their specific needs, enhancing the versatility of the welding operations.

Factors Influencing the Selection of E7016 Electrodes

When selecting E7016 electrodes for a specific welding project, several factors must be taken into account

1. Welding Position The type of welding position (flat, horizontal, vertical, or overhead) can affect the choice of electrode. E7016 electrodes excel in versatility, making them suitable for various welding positions.

2. Base Material The type and thickness of the base materials being welded are vital considerations. E7016 electrodes are ideal for mild steel and low alloy steel applications, particularly where high strength is required.

3. Environmental Conditions The welding environment—such as outdoor versus indoor work and exposure to wind or rain—can influence the selection of electrode. E7016 electrodes are designed to perform well in adverse conditions, making them a reliable option.

4. Welder Skill Level The experience and skill level of the welder can dictate the type of electrodes chosen. E7016 electrodes offer good arc stability, which can be particularly beneficial for welders who may not have extensive experience.

Conclusion

E7016 welding electrodes represent a critical component in the world of welding, particularly within the context of China’s expansive manufacturing sector. Their strength, adaptability, and the capability to perform in various conditions make them a favored choice among welders. Furthermore, as the demand for high-quality welding consumables continues to grow globally, Chinese factories are well-positioned to supply efficient, cost-effective, and reliable E7016 electrodes. As industries evolve and technology advances, the role of electrodes like E7016 will remain integral in shaping the future of welding practices worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025