Aluminum Welding Rods Supplier for Quality Welding Solutions in China

The Growing Demand for Aluminum Welding Rods in China

In recent years, the demand for aluminum welding rods has seen a notable increase, driven by advancements in industries such as construction, automotive, and aerospace

. As a significant player in this market, China has emerged as a leading supplier of aluminum welding rods, catering to both domestic and international needs.Aluminum is widely recognized for its lightweight, strong, and corrosion-resistant properties, making it an ideal material for various applications. The welding of aluminum presents unique challenges, such as its high thermal conductivity and susceptibility to oxidation. Therefore, specialized welding rods are essential for ensuring a strong and quality joint. Chinese suppliers have stepped up to meet this demand by offering a variety of aluminum welding rods tailored to different applications.

One of the primary reasons for the growing popularity of aluminum welding rods in China is the country’s booming construction industry. With large-scale infrastructure projects taking place, including bridges, buildings, and public transport systems, the need for efficient welding solutions has skyrocketed. Aluminum is often preferred for its lightweight nature, which reduces structural load while maintaining strength. Chinese manufacturers are developing advanced welding rods that are designed for a range of welding techniques, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, to enhance productivity and efficiency.

In addition to the construction sector, the automotive industry is another significant market for aluminum welding rods. As automobile manufacturers increasingly move towards lightweight materials to improve fuel efficiency and reduce emissions, aluminum has become a staple in vehicle design. This shift creates a robust demand for high-quality aluminum welding rods that can withstand the rigorous conditions of automotive applications. Chinese suppliers are consistently innovating, producing welding rods that offer improved performance and better joint integrity to meet this trend.

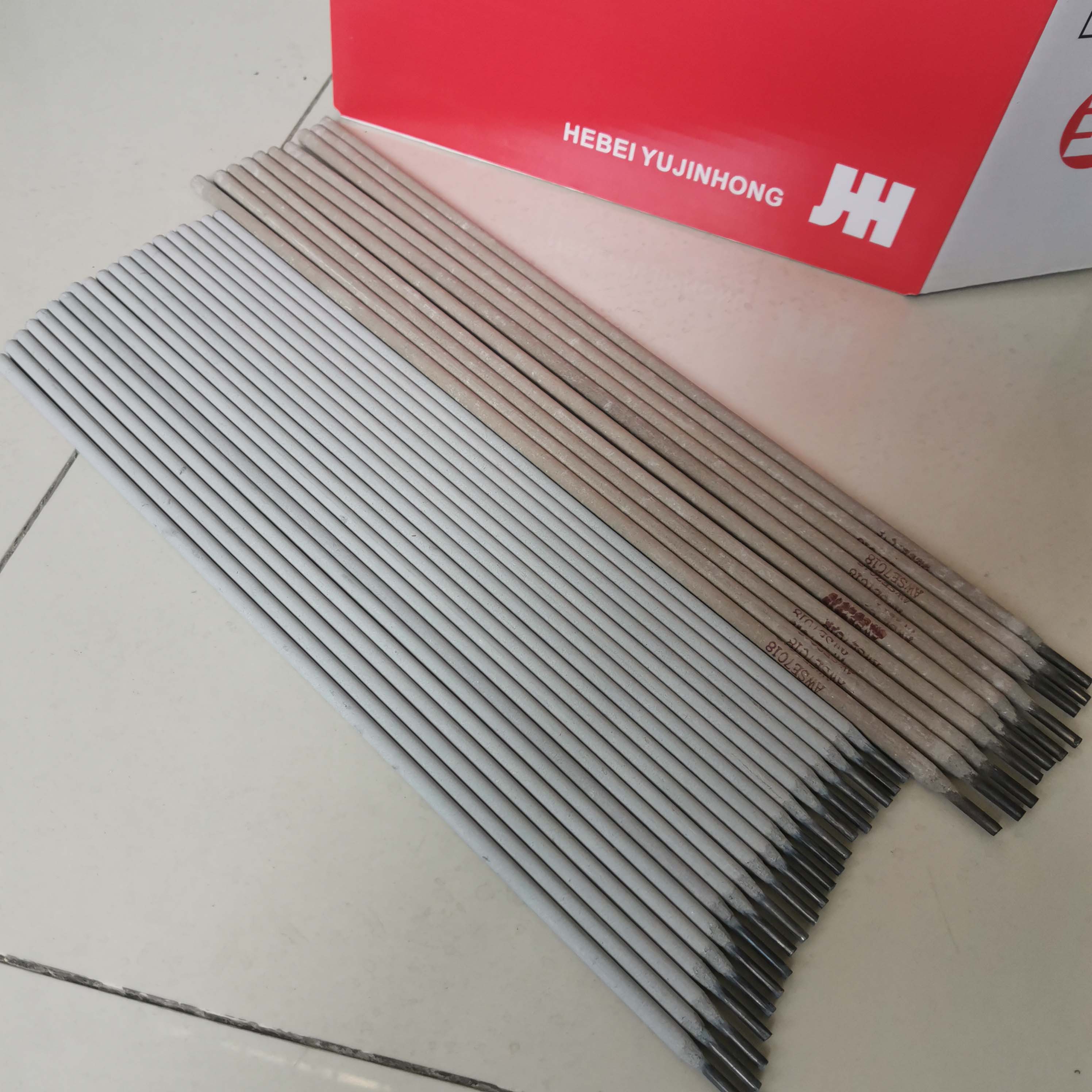

china welding rod aluminum stick supplier

Furthermore, the aerospace sector is also experiencing a growing interest in aluminum welding. Aircraft construction often requires the use of aluminum for its favorable strength-to-weight ratio. As the industry looks to integrate more aluminum components for fuel efficiency, the necessity for specialized welding rods becomes even more critical. In response, Chinese aluminum welding rod suppliers are investing in research and development to create products that comply with stringent aerospace standards.

Competition among suppliers has led to improvements in quality and affordability of aluminum welding rods. Chinese manufacturers are leveraging modern technology and efficient production processes to provide high-quality products at competitive prices. Many of these suppliers offer a variety of options, including different diameters, alloys, and coatings, to suit various customer needs.

Moreover, as environmental concerns continue to rise, there is a growing emphasis on sustainable manufacturing practices. Chinese suppliers are also embracing eco-friendly production methods, ensuring that their products are not only effective but also environmentally responsible.

In conclusion, the market for aluminum welding rods in China is rapidly evolving, driven by various industries that appreciate the advantages of aluminum. With a focus on quality, innovation, and sustainability, Chinese suppliers are well-positioned to meet the increasing demand for aluminum welding rods both domestically and globally. As these trends continue to develop, the role of Chinese suppliers in the global aluminum welding market is likely to expand even further, reinforcing their position as key players in this dynamic industry.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025