china welding rod for aluminum suppliers

Exploring Aluminum Welding Rod Suppliers in China

In recent years, the demand for high-quality welding materials, particularly aluminum welding rods, has surged due to the increasing use of aluminum in various industries. Aluminum’s lightweight and corrosion-resistant properties make it ideal for applications in automotive, aerospace, construction, and marine fabrication. As a result, finding reliable aluminum welding rod suppliers has become imperative for manufacturers around the globe. China, known as a global manufacturing powerhouse, has emerged as a key player in supplying aluminum welding rods.

The Importance of Aluminum Welding Rods

Aluminum welding rods play a crucial role in the welding process, ensuring strong and durable joints between aluminum components. These rods come in various grades and types, including ER4047, ER4045, and ER5356, each designed for specific applications and welding processes, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. The choice of welding rod significantly affects the quality of the weld, making it essential for buyers to source high-quality products that meet their specific requirements.

Why Choose Chinese Suppliers?

1. Cost-Effectiveness One of the most significant advantages of sourcing aluminum welding rods from China is cost efficiency. Chinese manufacturers often benefit from lower production costs due to the availability of raw materials, advanced manufacturing technologies, and economies of scale. This results in competitive pricing for high-quality aluminum welding rods, enabling businesses to reduce their operational costs.

2. Variety and Customization Chinese suppliers typically offer a broad range of products and can provide customized solutions to meet unique client specifications. This flexibility is crucial for businesses that require specific grades of welding rods for specialized applications. Suppliers can alter the chemical composition and physical properties of the rods, ensuring that they meet international standards and customer expectations.

3. Advanced Technology and Quality Assurance Many Chinese manufacturers leverage advanced welding technologies and strict quality control measures to produce aluminum welding rods that meet industry standards. These companies often invest in modern equipment and adhere to international certifications such as ISO 9001, ensuring that their products are reliable and of the highest quality.

4. Strong Supply Chain and Logistics China has developed a robust supply chain network and logistics system, which facilitates timely delivery and efficient transportation of goods. This is particularly beneficial for companies that rely on just-in-time inventory systems, ensuring that they do not face delays in production due to a lack of essential materials.

china welding rod for aluminum suppliers

Factors to Consider When Choosing Suppliers

While the advantages of sourcing from Chinese suppliers are evident, businesses must consider several factors when selecting a supplier for aluminum welding rods

1. Reputation and Experience It is crucial to research the supplier's reputation in the industry. Look for manufacturers with significant experience and a proven track record of delivering quality products. Customer reviews, certifications, and industry awards can provide insight into a supplier’s reliability.

2. Product Range Ensure that the supplier offers a comprehensive range of aluminum welding rods that meet your specific requirements. This includes various types, sizes, and specifications that align with your projects.

3. Quality Control Processes Inquire about the supplier's quality control measures and testing protocols. Reputable manufacturers will have stringent processes to monitor the quality of their products consistently.

4. Customer Support A reliable supplier should provide excellent customer service, including responsiveness to inquiries, assistance with technical questions, and support during the ordering process.

5. Terms and Conditions Before finalizing any agreement, review the supplier's terms and conditions, including payment terms, delivery times, and warranty policies.

Conclusion

In conclusion, sourcing aluminum welding rods from Chinese suppliers offers numerous advantages, including cost-effectiveness, product variety, and advanced manufacturing capabilities. However, businesses must conduct thorough research and consider critical factors to ensure that they partner with a reliable supplier. By carefully selecting a reputable manufacturer, companies can enhance their production processes, reduce costs, and ultimately improve the quality of their finished products. As the global demand for aluminum continues to rise, so too will the importance of sourcing high-quality welding materials that can meet the challenges of modern manufacturing.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

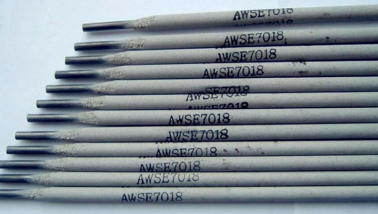

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025