China 1.2mm Welding Wire Manufacturing Facilities and Production Insights

The Rise of China’s 1.2mm Welding Wire Factories

In recent years, China's manufacturing sector has witnessed a remarkable evolution, establishing itself as a global leader in various industries, including the production of welding wire. Among these products, 1.2mm welding wire has gained substantial popularity for its versatility and efficiency in various welding applications. With a combination of advanced technology, skilled labor, and cost-effectiveness, China’s welding wire factories are increasingly becoming pivotal in meeting global demands.

Understanding 1.2mm Welding Wire

Welding wire comes in various diameters, with 1.2mm being one of the most commonly used sizes. It is primarily employed in gas metal arc welding (GMAW) processes, making it ideal for industries such as automotive, construction, and manufacturing. The 1.2mm format provides optimal feedability, increases welding speed, and yields strong, high-quality welds. These characteristics make it an essential component for professionals seeking reliable performance.

The Advantage of Chinese Factories

One of the main advantages of Chinese factories producing 1.2mm welding wire is cost efficiency. With lower labor costs and the ability to scale production, Chinese manufacturers can offer competitive prices without compromising on quality. This makes it easier for businesses around the world to access high-quality welding materials at affordable rates.

Moreover, China boasts a robust supply chain system that ensures the availability of raw materials needed for manufacturing welding wire. This efficiency contributes to lower production costs, which can be passed on to the customers. Chinese manufacturers typically utilize high-quality steel and advanced alloy compositions, further enhancing the performance of the welding wire.

Technological Advancements

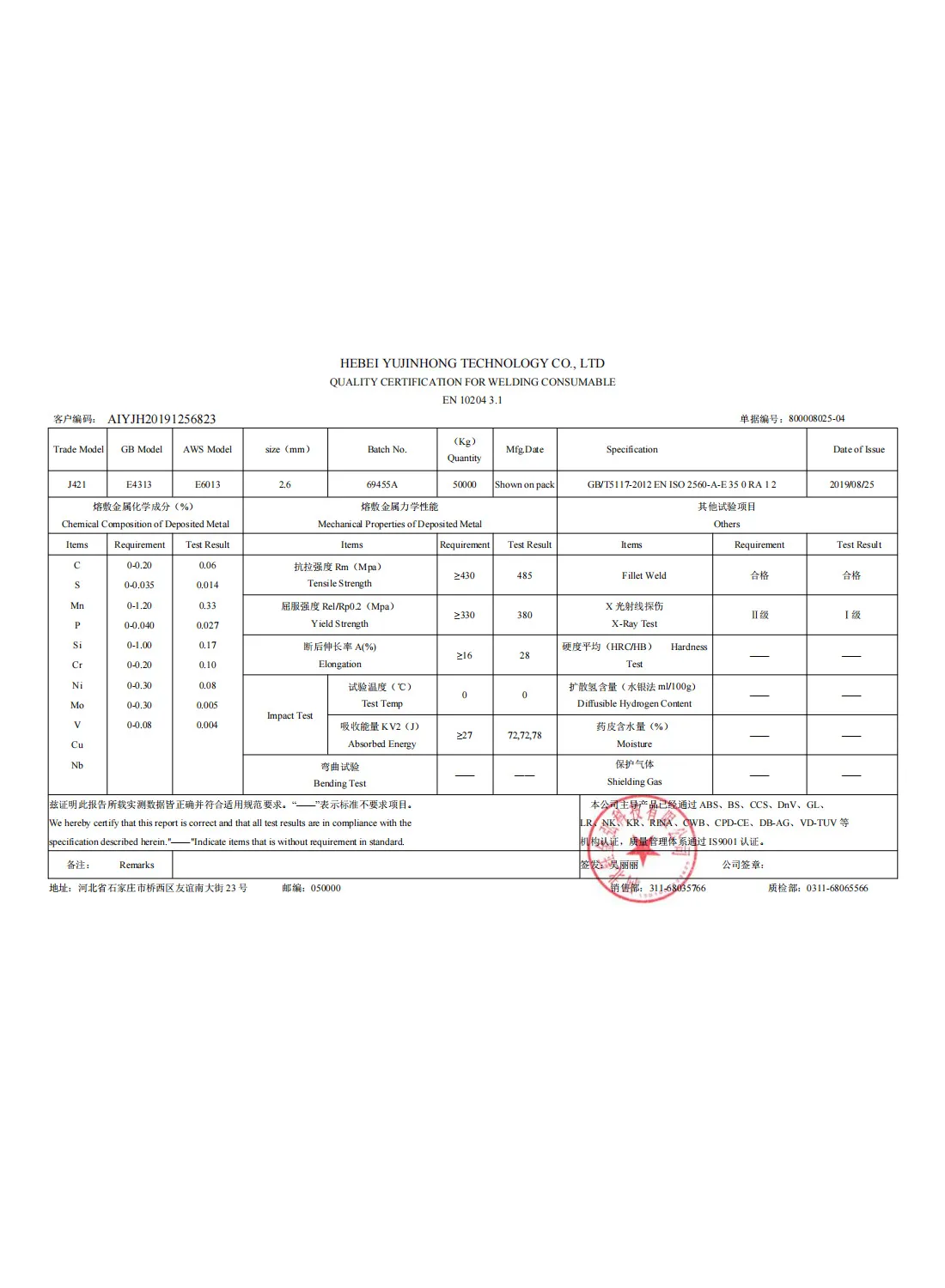

china welding wire 1.2mm factories

China's investment in modern technology and manufacturing processes has significantly improved the quality of its welding wire. Many factories have adopted automated production lines that increase precision and consistency while reducing human error. Furthermore, the application of quality control measures throughout the manufacturing process guarantees that products meet international standards, making Chinese 1.2mm welding wire reliable for global markets.

Additionally, research and development in Chinese factories have led to innovative welding wire formulations. Enhancements in coating technology provide better protection against oxidation and improve arc stability during welding. Such developments reflect a commitment to meeting the evolving needs of customers and adapting to new welding techniques.

Meeting Global Demands

As the global construction and manufacturing sectors continue to expand, the demand for high-quality welding materials has surged. Chinese factories have positioned themselves to fulfill these growing needs by ramping up production and improving export logistics. The Belt and Road Initiative has also played a crucial role in enhancing trade routes and facilitating smoother international transactions, allowing Chinese welding wire to reach diverse markets worldwide.

Moreover, China's strategic focus on quality and customer service has led to the establishment of strong relationships with international clients. Manufacturers often provide additional services, such as technical support and training, to ensure end-users can maximize the potential of their welding products.

Conclusion

With its combination of cost efficiency, technological advancement, and quality assurance, China’s 1.2mm welding wire factories have become essential players in the global welding industry. As they continue to innovate and expand their reach, these manufacturers not only contribute to the global supply chain but also support the growth of various sectors that depend on reliable welding solutions. As we look to the future, China's role in the welding wire market is poised to strengthen even further, solidifying its status as a key provider of welding materials worldwide.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025