china welding wire flux core

Exploring China’s Welding Wire Flux Core Industry

Welding is a critical process in numerous industries, ranging from construction to manufacturing, and the materials used in welding play a significant role in the quality and efficiency of the work performed. Among the various materials used in welding, flux-cored welding wire is gaining increasing popularity, particularly in China, which has become a leading manufacturer and supplier of welding wire products globally. This article delves into the importance of flux-cored welding wire, its applications, and the impact of China’s manufacturing capabilities on the global market.

An Overview of Flux-Cored Welding Wire

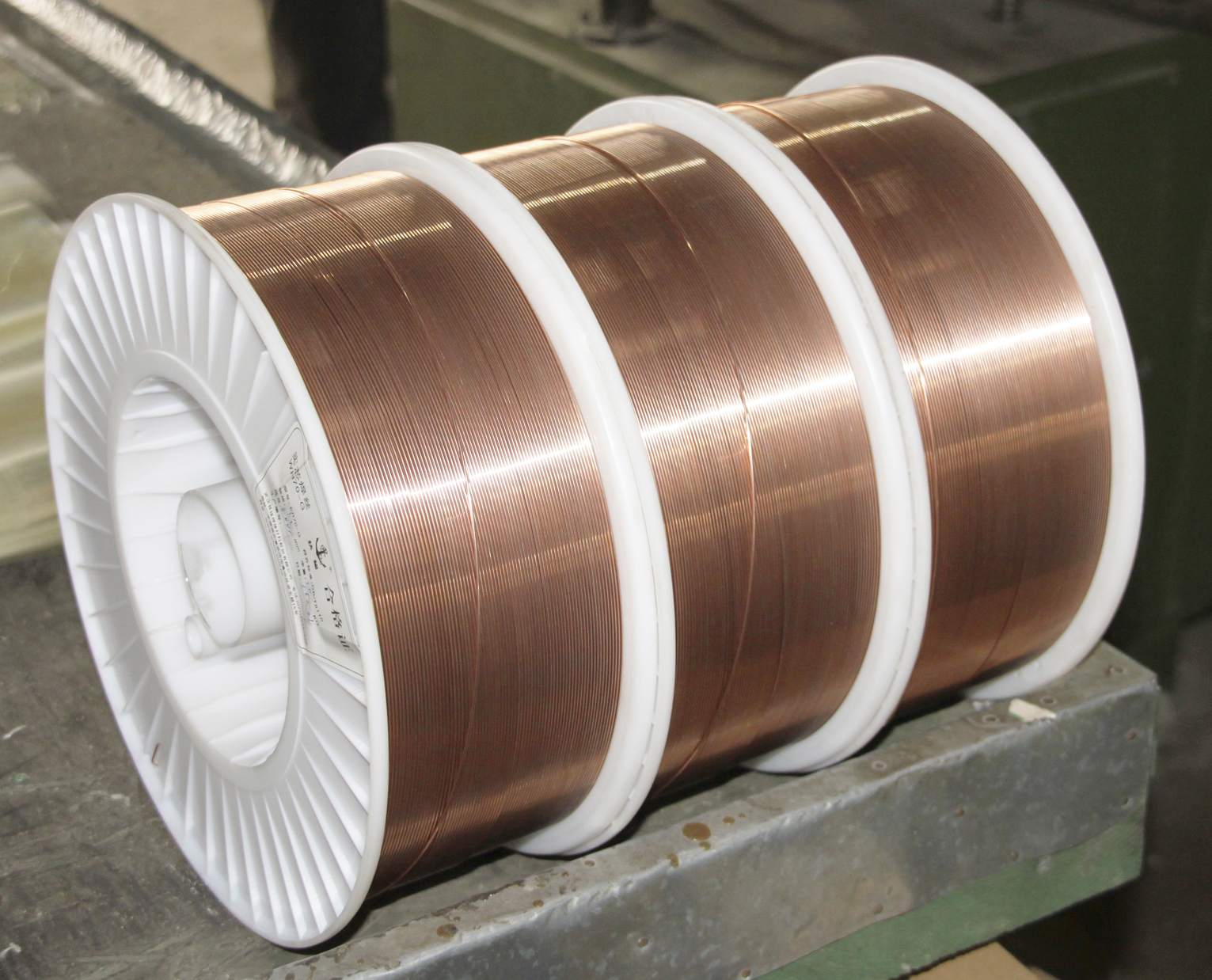

Flux-cored welding wire is a type of consumable electrode used in welding processes that provides a tubular wire filled with flux. The primary advantage of using flux-cored wire is that it allows for efficient, high-speed welding with excellent penetration and a smoother finish compared to other welding wires. Unlike conventional solid wires, the flux core serves as both a shielding agent to protect the weld pool from contamination and a source of additional alloys to enhance the final weld’s properties.

This flexible and versatile welding technology can be used in various environments, including outdoor and windy conditions where using solid wires might present challenges. The adaptability of flux-cored wire makes it particularly appealing for construction sites, shipbuilding, and heavy machinery repairs, where robustness and resilience are crucial.

China’s Role in the Welding Wire Market

China is becoming a global leader in the production of welding materials, including flux-cored welding wire. The country boasts a diverse range of manufacturers, from large corporations to smaller niche companies, enabling it to cater to both local and international markets. The growth of China’s welding wire sector can be attributed to several factors

1. Massive Production Capabilities Chinese manufacturers benefit from economies of scale, allowing them to produce large volumes of welding wire at competitive prices. This capability helps attract businesses looking for cost-effective supply chains.

china welding wire flux core

2. Advanced Technology and Innovation Over the years, many Chinese firms have invested heavily in advanced manufacturing technologies. As a result, they are now capable of producing high-quality welding wire that meets international standards. Continuous innovation ensures that they remain competitive in a rapidly evolving market.

3. Export Opportunities With a robust supply chain and the ability to produce high-quality products at lower costs, China has become a major exporter of welding wire. Countries worldwide are increasingly sourcing their welding materials from China, further establishing its dominance in the global market.

4. Diverse Applications The versatility of flux-cored welding wires allows manufacturers to target varied industries, including automotive, construction, and pipeline construction. By offering customized solutions for specific applications, Chinese manufacturers enhance their attractiveness to a wide range of clients.

Challenges and Opportunities

While China enjoys significant advantages in the welding wire market, challenges remain. Domestic competition is fierce, pushing manufacturers to continually innovate and improve quality. Compliance with international standards and environmental regulations is also becoming more stringent. Manufacturers must invest in sustainable practices to ensure their products are not only competitive but also responsible.

On the other hand, these challenges present opportunities. As industries worldwide increasingly prioritize sustainability, companies that focus on eco-friendly production methods may find themselves ahead of the curve. Additionally, with the rise of new technologies in welding, such as automation and artificial intelligence, Chinese manufacturers can further enhance their efficiencies and product offerings.

Conclusion

China’s welding wire flux core industry plays an essential role in international welding applications. Through continuous investment in technology, production capabilities, and adherence to quality standards, Chinese manufacturers have positioned themselves as key players in the global market. As industries continue to evolve and demand more efficient and reliable soldering materials, the importance of high-quality flux-cored welding wire from China will only increase, providing exciting growth prospects for manufacturers and customers alike.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025