china welding wire flux core factory

The Evolution and Importance of Welding Wire Flux Core Factories in China

The welding industry has evolved significantly over the years, and one of its key components is the welding wire, particularly flux-cored wire. In China, the welding wire flux core factory plays a crucial role in the production of high-quality welding materials that cater to diverse industrial requirements. This article will delve into the significance of these factories, the technology behind them, and their contribution to the global welding market.

Understanding Flux-Cored Welding Wire

Flux-cored arc welding (FCAW) is a semi-automatic or automatic process that uses a continuously fed tubular wire filled with flux to create a weld. This type of welding wire offers several advantages, including excellent penetration, reduced spatter, and the ability to be used in various positions. The core of the wire contains a flux material that generates gases during welding, which protects the molten weld pool from contamination by atmospheric gases.

The Role of Factories in Production

China's welding wire flux core factories are equipped with state-of-the-art technology that enhances production efficiency and product quality. These factories utilize advanced machinery and automated processes to produce flux-cored wires that meet international standards. The production process involves several stages, including wire drawing, flux filling, and welding wire coating. Each stage is monitored for quality control, ensuring that the final products are reliable and durable.

Moreover, these factories employ skilled workers who are trained in various aspects of welding technology. Their expertise is essential for maintaining the production line and improving manufacturing techniques. As a result, Chinese factories have gained a reputation for producing some of the highest-quality welding wires globally.

Innovations in Welding Wire Production

Innovation is at the heart of China's manufacturing sector, and welding wire flux core factories are no exception. Many manufacturers are investing in research and development to create wires that offer better performance, increased efficiency, and environmentally friendly options. Innovative welding wires are being designed to withstand extreme temperatures and corrosive environments, making them ideal for industries such as construction, shipbuilding, and automotive manufacturing.

china welding wire flux core factory

Additionally, the push for sustainability has led to the development of eco-friendly flux-cored wires that reduce emissions and environmental impact. These advancements not only contribute to the environment but also enhance the overall quality of welding processes.

Contribution to the Global Market

China is one of the largest producers of welding wires in the world, and its factories export products to various countries. The competitive pricing, consistent quality, and technological advancements make Chinese flux-cored wires attractive to international buyers. As industries worldwide continue to grow, the demand for high-quality welding materials increases, providing Chinese factories with ample opportunities for expansion in the global market.

Challenges and Future Prospects

Despite the successes, welding wire flux core factories in China face challenges such as fluctuating raw material costs, competition from other countries, and the need for continuous innovation. To stay ahead, manufacturers must adapt to market trends and focus on enhancing their product offerings. Embracing digital technologies and automation can also streamline operations and reduce costs.

Furthermore, with the increasing emphasis on sustainability and green technologies, factories will need to invest in environmentally friendly practices and materials. This focus is not only essential for compliance with global regulations but also for meeting the expectations of environmentally conscious consumers.

Conclusion

Welding wire flux core factories in China play a pivotal role in the global welding industry. Their commitment to quality, innovation, and sustainability positions them as key players in meeting the growing demand for effective welding solutions. As the industry continues to evolve, these factories will undoubtedly contribute significantly to the advancement of welding technologies and materials worldwide. With ongoing investment in research and development, China’s welding wire industry is poised for a bright future.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

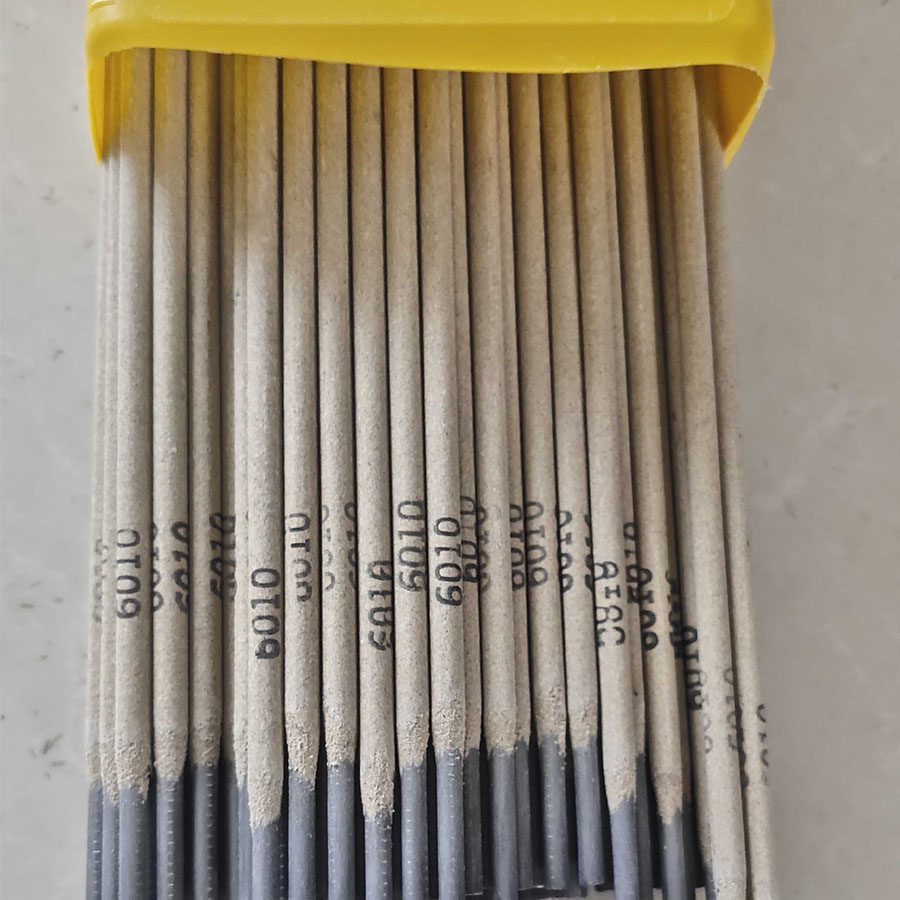

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025