Exploring the Benefits of MIG Welding for Wire Fabrication in China

Understanding China Wire Welding An Insight into MIG Technology

In recent years, China has emerged as a global leader in manufacturing and exporting a variety of industrial equipment, including advanced welding technologies. Among these technologies, Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), has gained particular prominence due to its efficiency and versatility. This article delves into the specifics of MIG welding in China, highlighting its processes, advantages, and the country's role in the global welding market.

The Process of MIG Welding

MIG welding is a continuous process that utilizes a consumable wire electrode and a shielding gas to protect the weld pool from contamination. The wire is fed through a welding gun, where it melts and fuses the base metals together when an electric arc is created. This method is particularly effective for welding thin sections of stainless steel and non-ferrous metals.

In China, the MIG welding process has been refined with advanced technology, enabling greater precision and speed. The use of robotic systems in manufacturing has further improved the consistency and quality of MIG welds, making it an ideal choice for large-scale production.

Advantages of MIG Welding

One of the primary advantages of MIG welding is its high deposit rate, which significantly reduces the time and cost associated with welding projects. The technique is also easy to learn, making it accessible for both professional welders and hobbyists. Additionally, MIG welding is characterized by a clean and neat finish, reducing the need for post-weld cleanup.

In China, MIG welding has found applications across multiple industries, including automotive, construction, and shipbuilding. Chinese manufacturers have adopted MIG welding technology to enhance their production capabilities, ensuring that they remain competitive in the global market.

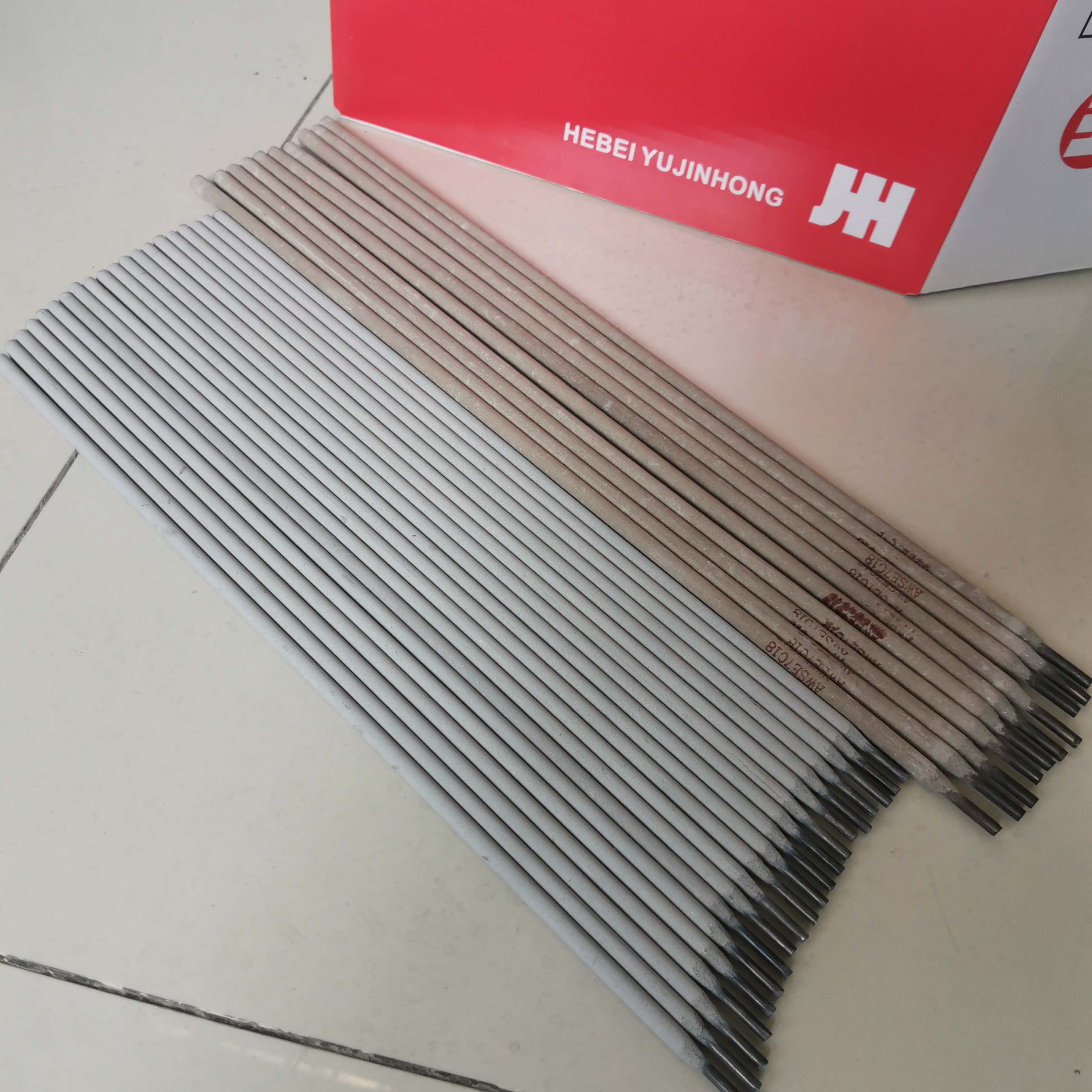

china wire welding mig

China’s Role in the MIG Welding Industry

China’s robust manufacturing sector has made it a central player in the global welding equipment market. The country produces a wide range of MIG welding machines, from basic models ideal for home use to advanced industrial systems designed for heavy-duty applications. Chinese manufacturers benefit from economies of scale, allowing them to offer competitive pricing while maintaining quality.

Moreover, with the rapid development of technology, many Chinese companies have invested in research and development to innovate new welding processes and improve existing ones. Collaborations with international firms have also facilitated knowledge transfer, enabling Chinese manufacturers to enhance their technological capabilities.

Future Trends in MIG Welding in China

Looking forward, the future of MIG welding in China appears promising. As industries rapidly evolve, there is an increasing demand for automation and digitalization in welding processes. The integration of artificial intelligence and machine learning into MIG welding applications is likely to improve efficiency and precision even further.

Furthermore, the push toward sustainable practices is influencing the welding industry. Chinese manufacturers are exploring eco-friendly gases and welding methods that minimize environmental impact. This trend aligns with China’s broader commitment to sustainable development and reducing carbon emissions.

Conclusion

MIG welding stands out as a key technology in China’s industrial landscape, characterized by its efficiency, adaptability, and growing importance in various sectors. As China continues to innovate and lead in the welding equipment market, the role of MIG welding is set to expand further, offering exciting opportunities for both manufacturers and consumers alike. Through ongoing advancements and a commitment to quality, China's influence on the global welding industry is likely to remain strong in the years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025