Choosing the Right 4mm E7018 Welding Rod for Your Next Project and Its Applications

Understanding the E7018 4mm Welding Rod An Essential Tool for Welders

Welding is a critical process in many industrial applications, and the choice of welding rod plays a crucial role in achieving strong, durable joints. Among the various options available, the E7018 welding rod stands out for its suitability in producing high-quality welds in mild and low alloy steels. Specifically, the 4mm diameter variant of E7018 rods is particularly popular among professional welders for several reasons, which we will explore in this article.

Composition and Characteristics

The E7018 welding rod is classified as an electrode that produces low-hydrogen welds, which is imperative for minimizing defects such as cracking. The E in E7018 signifies that it is an electrode, while 70 indicates the minimum tensile strength of the weld bead, measured in thousands of psi (pounds per square inch). The 1 refers to its position in welding (all positions), and the 8 signifies that it contains a low hydrogen level, which reduces the risk of hydrogen-induced cracking.

The composition of E7018 rods typically includes a blend of iron powder, manganese, silicon, and a small percentage of nickel. These elements contribute not only to the strength but also to the toughness of the welds. The 4mm diameter is especially advantageous for detailed work or for welding thin materials, making it a favorite among fabricators and construction professionals.

Advantages of E7018 4mm Welding Rods

1. User-Friendly The 4mm E7018 rods are relatively easy to handle, making them suitable for both skilled welders and those who are still mastering the craft. Their design enables smooth arc stability and optimal penetration, reducing the likelihood of defects such as porosity and slag inclusion.

2. Versatility E7018 rods can be used on various materials, including carbon steels and low-alloy steels. Their versatility allows welders to tackle a wide range of projects, from structural fabrication to repairing machinery.

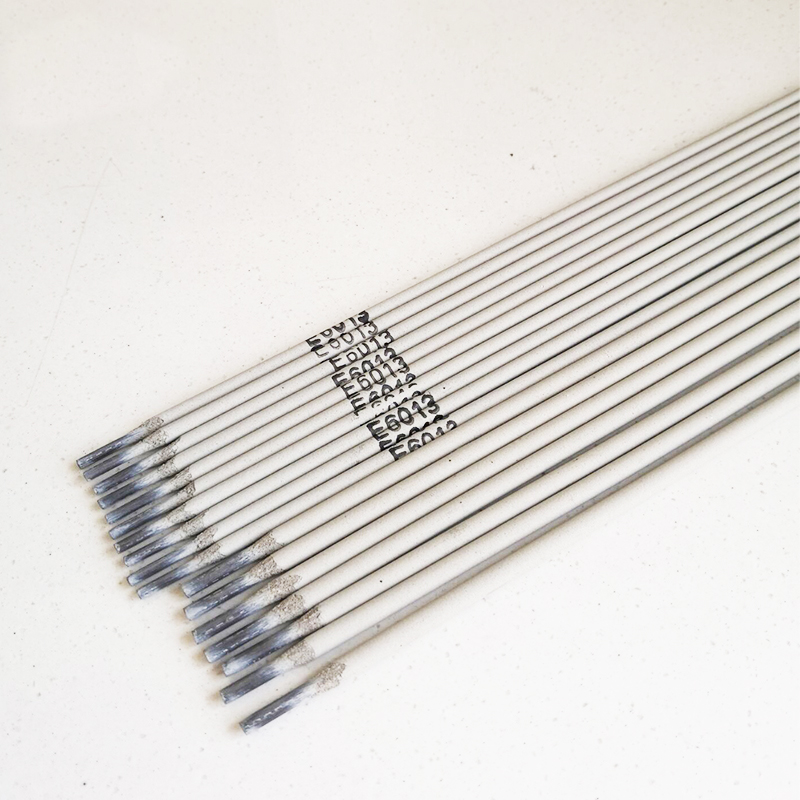

4mm welding rod e7018

3. High-quality Welds When used correctly, the E7018 welding rod produces strong, ductile welds with a clean finish. This is particularly advantageous in applications where weld integrity is crucial, such as in bridges, buildings, and pressure vessels.

4. Resistance to Cracking The low-hydrogen characteristics of E7018 rods significantly reduce the risk of cracks forming in the weld due to thermal stresses. This feature is vital in applications where welds will be exposed to changing temperatures or harsh conditions.

5. Excellent Performance in All Positions The ability to weld in various positions—flat, horizontal, vertical, and overhead—without compromising the quality of the weld makes the E7018 4mm rod an invaluable tool in the field.

Considerations for Use

While the E7018 welding rod offers numerous benefits, it is essential to follow some best practices to ensure optimal weld quality. Rods should be stored in a dry environment to prevent moisture absorption, which can lead to hydrogen embrittlement. Additionally, proper preheating of the base metal may be necessary in some cases to enhance the fusion of the weld.

Conclusion

The E7018 4mm welding rod is a versatile and reliable choice for professionals in the welding industry. With its low-hydrogen characteristics and ability to produce high-quality welds across various positions, it is an essential tool for anyone looking to achieve strong and durable welds. Whether you are involved in construction, fabrication, or repair work, understanding and utilizing the E7018 can significantly enhance the outcomes of your welding projects.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025