Choosing the Right Supplier for Quality Welding Stick Electrodes and Their Applications

The Essential Role of Welding Stick Electrode Suppliers in Modern Manufacturing

Welding has long been a critical technology in the construction and manufacturing industries, and at the heart of this process lies the welding stick electrode. These electrodes are vital components that facilitate the joining of metals through the welding process, significantly impacting the efficiency, quality, and overall effectiveness of welding operations. As a result, the role of welding stick electrode suppliers is increasingly central in meeting the demands of various sectors.

Welding stick electrodes come in several types, each designed for specific applications. From mild steel to stainless steel and cast iron, the variety of materials requires suppliers to have a comprehensive understanding of welding products. Suppliers often categorize electrodes based on their composition, manufacturing process, and intended use, which may include stick welding, shielded metal arc welding (SMAW), and more. A knowledgeable supplier ensures that customers can select the right electrode for their specific task, enhancing performance and safety during the welding process.

Quality is paramount when it comes to welding stick electrodes. The integrity of welds can have significant implications, especially in industries such as construction, automotive, and aerospace, where safety is a top priority. Suppliers must adhere to strict industry standards and guidelines to guarantee their products’ quality and reliability. Certifications and compliance with international standards, such as those set by the American Welding Society (AWS) or the International Organization for Standardization (ISO), provide reassurance to customers and enhance a supplier's credibility in the market.

Moreover, as technology advances, the demand for specialized welding electrodes has risen. This evolution has led suppliers to invest in research and development to produce cutting-edge products that meet the changing needs of modern welding situations. This includes the creation of multipurpose electrodes, those capable of welding a diverse array of materials and thicknesses, and low-hydrogen electrodes that reduce crack formation and improve performance. A committed supplier keeps pace with these technological advancements, ensuring that their offerings remain relevant and efficient.

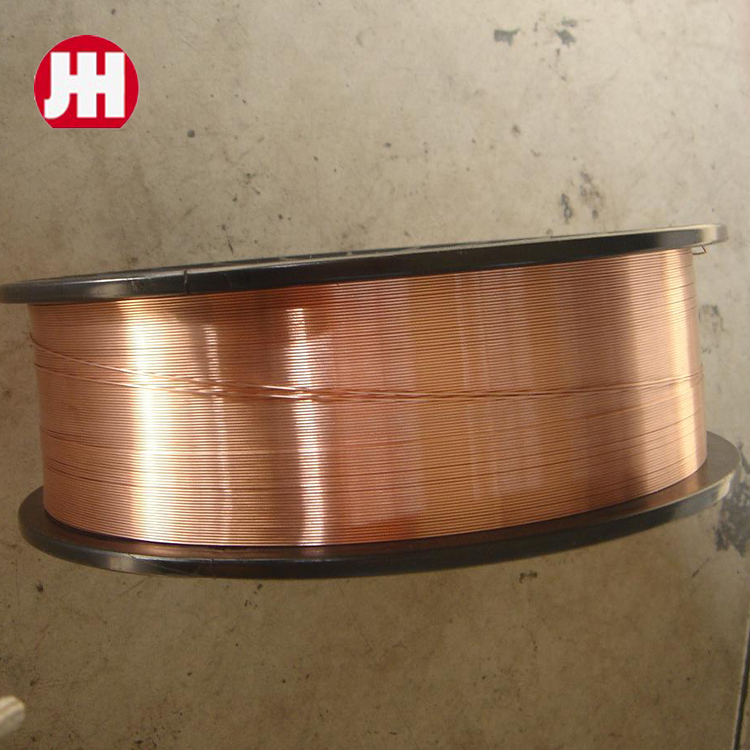

welding stick electrode supplier

In addition to product quality and variety, suppliers also play a crucial role in customer service and support. Understanding the welding process can be complicated, especially for businesses choosing the right electrodes for unique projects. Therefore, reliable suppliers not only offer an extensive range of products but also provide expert guidance and support. This level of service can include advice on electrode selection, training on proper welding techniques, and troubleshooting for various challenges that may arise.

Additionally, welding stick electrode suppliers often engage in sustainability initiatives as environmental concerns become more prominent. Many manufacturers are opting for eco-friendly practices, and suppliers must support these efforts by providing products with a reduced carbon footprint. This can involve offering recycled or sustainably sourced materials, as well as promoting proper waste management practices throughout the supply chain.

In a globalized economy, sourcing welding stick electrodes from reputable suppliers is essential for maintaining competitive advantages. The efficiency of supply chains, timeliness of deliveries, and overall reliability influence project budgets and timelines. As welding operations become more integrated into automated processes, suppliers must be adaptable and responsive to ensure that manufacturers can rely on them for consistent quality and availability.

In conclusion, the role of welding stick electrode suppliers is multifaceted and crucial to the success of modern manufacturing and construction industries. From ensuring product quality and offering a wide range of specialty products to providing invaluable customer support and embracing sustainable practices, these suppliers are essential partners in the welding process. As the industry continues to evolve, so too will the responsibilities and offerings of welding stick electrode suppliers, reaffirming their importance in the ever-changing landscape of manufacturing and construction.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025