CO2 Gas Shielded Copper Plated Micro Wire - HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|Low Spatter&High Cladding Efficiency

Introduction to CO2 Gas Shielded Copper Plated Micro Wire

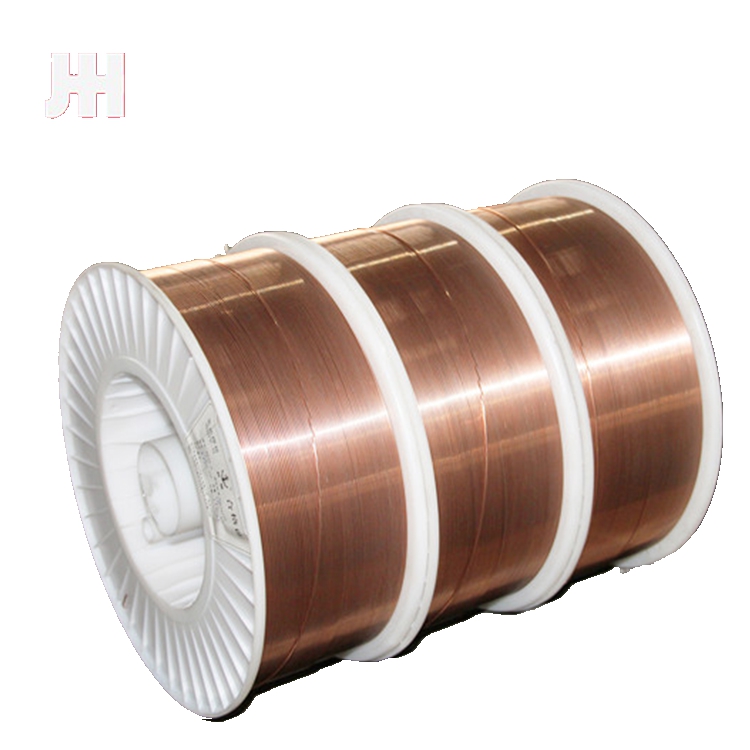

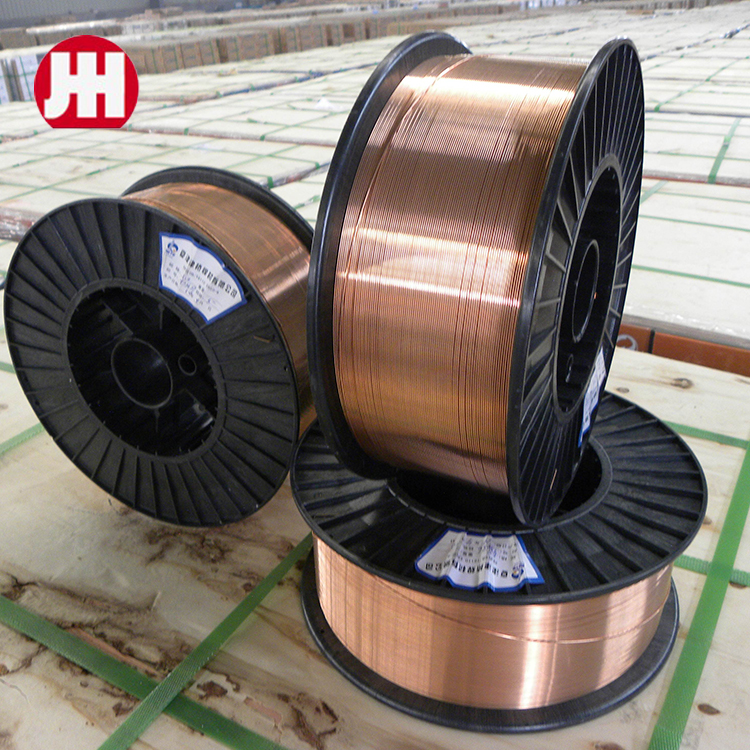

The CO2 Gas Shielded Copper Plated Micro Wire is a cutting-edge welding solution designed for high-performance applications in the manufacturing and construction sectors. This product, specifically the ER70S-6 carbon steel wire, is engineered to deliver exceptional welding results with minimal spatter, superior cladding efficiency, and excellent resistance to weld metal porosity. Developed by HEBEI YUJINHONG TECHNOLOGY CO.,LTD., this wire is a testament to advanced production technology and rigorous quality control. The copper plating on the wire not only enhances its corrosion resistance but also improves electrical conductivity, ensuring smooth and efficient welding operations. This article delves into the product's features, advantages, technical specifications, and applications, highlighting its role in modern industrial welding.

Key Features of CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire is distinguished by its exceptional performance characteristics, making it a preferred choice for various welding applications. One of its most notable features is its ability to produce a beautiful weld appearance with minimal spatter. This is achieved through the use of advanced production technology, which ensures a stable arc and consistent melting speed during welding. Additionally, the wire's copper plating enhances its oxidation and corrosion resistance, extending its shelf life and ensuring reliable performance even in harsh environments.

Another critical feature is the wire's high cladding efficiency, which allows for faster welding processes and reduced material waste. This is particularly beneficial in industrial settings where productivity and cost-effectiveness are paramount. The wire is also compatible with both CO2 gas and 80% Ar + 20% CO2 shielding gases, offering flexibility in different welding conditions. Furthermore, the wire's low sensitivity to weld metal porosity ensures a high-quality weld with minimal defects, contributing to the structural integrity of the final product.

Advantages of CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire offers a range of advantages that make it a superior choice for industrial welding applications. One of its primary benefits is its low welding cost, which is achieved through high production efficiency and reduced material waste. This cost-effectiveness is further enhanced by the wire's low power consumption, making it an economical option for manufacturers. Additionally, the wire's ease of operation allows for all-position welding, which is particularly useful in complex or hard-to-reach areas.

The wire also excels in crack resistance due to its low hydrogen and nitrogen content, which minimizes the risk of weld defects. This is crucial in applications where structural integrity is a priority, such as in the construction of bridges or heavy machinery. Another significant advantage is the small deformation after welding, which reduces the need for post-welding corrections and saves time and resources. The wire's wide application range further enhances its value, as it can be used for welding thin, medium, and thick plates, making it a versatile solution for various industries.

Technical Specifications of CO2 Gas Shielded Copper Plated Micro Wire

| Parameter | Specification |

|---|---|

| Product Type | CO2 Gas Shielded Copper Plated Micro Wire |

| Material | Carbon Steel (ER70S-6) |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Welding Positions | PA, PB, PC, PD, PE, PF |

| Spatter | Low |

| Cladding Efficiency | High |

| Porosity Sensitivity | Low |

| Corrosion Resistance | Excellent (due to copper plating) |

| Electrical Conductivity | Enhanced |

| Shelf Life | Extended (due to copper plating) |

Applications of CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire is widely used in various industries due to its versatility and high performance. In the construction industry, it is employed for welding structural steel components, ensuring strong and durable connections. The wire's ability to handle all-position welding makes it ideal for complex structures such as bridges, towers, and high-rise buildings. In the manufacturing sector, it is used for assembling machinery, automotive parts, and industrial equipment, where precision and efficiency are critical.

The automotive industry also benefits from this product, as it is used for welding vehicle frames, chassis, and other structural components. The wire's low deformation after welding ensures that the final products meet stringent quality standards. In the shipbuilding industry, the wire is used for welding ship hulls and internal structures, where its corrosion resistance and durability are essential. Additionally, the energy sector utilizes this wire for constructing pipelines, storage tanks, and power generation equipment, where reliability and safety are paramount.

About HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is a leading manufacturer of high-quality welding consumables, dedicated to providing innovative solutions for the global market. With a focus on advanced production technology and rigorous quality control, the company ensures that its products meet the highest standards of performance and reliability. The CO2 Gas Shielded Copper Plated Micro Wire is a prime example of the company's commitment to excellence, combining cutting-edge technology with practical applications to meet the diverse needs of its customers.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. has established itself as a trusted name in the welding industry, serving clients across various sectors including construction, manufacturing, automotive, and energy. The company's dedication to innovation is reflected in its continuous research and development efforts, which aim to enhance product performance and expand its application range. By adhering to strict quality standards and maintaining a customer-centric approach, the company ensures that its products not only meet but exceed industry expectations.

Industry Standards and NIST Reference

The CO2 Gas Shielded Copper Plated Micro Wire is designed to comply with industry standards that ensure safety, quality, and performance. According to the National Institute of Standards and Technology (NIST), "Precise measurements and standards are essential for advancing technology and ensuring the reliability of industrial processes." NIST plays a crucial role in developing measurement standards that support various industries, including welding. While the specific standards for this product may not be explicitly mentioned in the provided context, the principles outlined by NIST emphasize the importance of rigorous testing and adherence to quality benchmarks, which are integral to the production of this wire.

As highlighted by NIST, "Standards and measurements are the foundation of innovation and economic growth." The CO2 Gas Shielded Copper Plated Micro Wire aligns with these principles by incorporating advanced technology and strict quality control measures to deliver a product that meets the demands of modern industrial applications.

Conclusion

The CO2 Gas Shielded Copper Plated Micro Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD. represents a significant advancement in welding technology, offering a combination of performance, efficiency, and reliability. Its features, such as low spatter, high cladding efficiency, and excellent corrosion resistance, make it an ideal choice for a wide range of industrial applications. The product's compliance with industry standards and its alignment with NIST's emphasis on precision and quality further underscore its value in the welding sector.

As industries continue to evolve, the demand for high-performance welding solutions will only grow. The CO2 Gas Shielded Copper Plated Micro Wire is well-positioned to meet these demands, providing manufacturers and construction professionals with a reliable and cost-effective solution. By choosing this product, businesses can enhance their welding operations, improve product quality, and achieve greater efficiency in their processes.

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025

CO2 Gas Shielded Copper Plated Micro Wire - HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|Low Spatter&High Cladding Efficiency

Introduction to CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire is a cutting-edge welding solution designed for high-performance applications in the manufacturing and construction sectors. This product, specifically the ER70S-6 carbon steel wire, is engineered to deliver exceptional welding results with minimal spatter, superior cladding efficiency, and excellent resistance to weld metal porosity. Developed by HEBEI YUJINHONG TECHNOLOGY CO.,LTD., this wire is a testament to advanced production technology and rigorous quality control. The copper plating on the wire not only enhances its corrosion resistance but also improves electrical conductivity, ensuring smooth and efficient welding operations. This article delves into the product's features, advantages, technical specifications, and applications, highlighting its role in modern industrial welding.

Key Features of CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire is distinguished by its exceptional performance characteristics, making it a preferred choice for various welding applications. One of its most notable features is its ability to produce a beautiful weld appearance with minimal spatter. This is achieved through the use of advanced production technology, which ensures a stable arc and consistent melting speed during welding. Additionally, the wire's copper plating enhances its oxidation and corrosion resistance, extending its shelf life and ensuring reliable performance even in harsh environments.

Another critical feature is the wire's high cladding efficiency, which allows for faster welding processes and reduced material waste. This is particularly beneficial in industrial settings where productivity and cost-effectiveness are paramount. The wire is also compatible with both CO2 gas and 80% Ar + 20% CO2 shielding gases, offering flexibility in different welding conditions. Furthermore, the wire's low sensitivity to weld metal porosity ensures a high-quality weld with minimal defects, contributing to the structural integrity of the final product.

Advantages of CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire offers a range of advantages that make it a superior choice for industrial welding applications. One of its primary benefits is its low welding cost, which is achieved through high production efficiency and reduced material waste. This cost-effectiveness is further enhanced by the wire's low power consumption, making it an economical option for manufacturers. Additionally, the wire's ease of operation allows for all-position welding, which is particularly useful in complex or hard-to-reach areas.

The wire also excels in crack resistance due to its low hydrogen and nitrogen content, which minimizes the risk of weld defects. This is crucial in applications where structural integrity is a priority, such as in the construction of bridges or heavy machinery. Another significant advantage is the small deformation after welding, which reduces the need for post-welding corrections and saves time and resources. The wire's wide application range further enhances its value, as it can be used for welding thin, medium, and thick plates, making it a versatile solution for various industries.

Technical Specifications of CO2 Gas Shielded Copper Plated Micro Wire

| Parameter | Specification |

|---|---|

| Product Type | CO2 Gas Shielded Copper Plated Micro Wire |

| Material | Carbon Steel (ER70S-6) |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Welding Positions | PA, PB, PC, PD, PE, PF |

| Spatter | Low |

| Cladding Efficiency | High |

| Porosity Sensitivity | Low |

| Corrosion Resistance | Excellent (due to copper plating) |

| Electrical Conductivity | Enhanced |

| Shelf Life | Extended (due to copper plating) |

Applications of CO2 Gas Shielded Copper Plated Micro Wire

The CO2 Gas Shielded Copper Plated Micro Wire is widely used in various industries due to its versatility and high performance. In the construction industry, it is employed for welding structural steel components, ensuring strong and durable connections. The wire's ability to handle all-position welding makes it ideal for complex structures such as bridges, towers, and high-rise buildings. In the manufacturing sector, it is used for assembling machinery, automotive parts, and industrial equipment, where precision and efficiency are critical.

The automotive industry also benefits from this product, as it is used for welding vehicle frames, chassis, and other structural components. The wire's low deformation after welding ensures that the final products meet stringent quality standards. In the shipbuilding industry, the wire is used for welding ship hulls and internal structures, where its corrosion resistance and durability are essential. Additionally, the energy sector utilizes this wire for constructing pipelines, storage tanks, and power generation equipment, where reliability and safety are paramount.

About HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is a leading manufacturer of high-quality welding consumables, dedicated to providing innovative solutions for the global market. With a focus on advanced production technology and rigorous quality control, the company ensures that its products meet the highest standards of performance and reliability. The CO2 Gas Shielded Copper Plated Micro Wire is a prime example of the company's commitment to excellence, combining cutting-edge technology with practical applications to meet the diverse needs of its customers.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. has established itself as a trusted name in the welding industry, serving clients across various sectors including construction, manufacturing, automotive, and energy. The company's dedication to innovation is reflected in its continuous research and development efforts, which aim to enhance product performance and expand its application range. By adhering to strict quality standards and maintaining a customer-centric approach, the company ensures that its products not only meet but exceed industry expectations.

Industry Standards and NIST Reference

The CO2 Gas Shielded Copper Plated Micro Wire is designed to comply with industry standards that ensure safety, quality, and performance. According to the National Institute of Standards and Technology (NIST), "Precise measurements and standards are essential for advancing technology and ensuring the reliability of industrial processes." NIST plays a crucial role in developing measurement standards that support various industries, including welding. While the specific standards for this product may not be explicitly mentioned in the provided context, the principles outlined by NIST emphasize the importance of rigorous testing and adherence to quality benchmarks, which are integral to the production of this wire.

As highlighted by NIST, "Standards and measurements are the foundation of innovation and economic growth." The CO2 Gas Shielded Copper Plated Micro Wire aligns with these principles by incorporating advanced technology and strict quality control measures to deliver a product that meets the demands of modern industrial applications.

Conclusion

The CO2 Gas Shielded Copper Plated Micro Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD. represents a significant advancement in welding technology, offering a combination of performance, efficiency, and reliability. Its features, such as low spatter, high cladding efficiency, and excellent corrosion resistance, make it an ideal choice for a wide range of industrial applications. The product's compliance with industry standards and its alignment with NIST's emphasis on precision and quality further underscore its value in the welding sector.

As industries continue to evolve, the demand for high-performance welding solutions will only grow. The CO2 Gas Shielded Copper Plated Micro Wire is well-positioned to meet these demands, providing manufacturers and construction professionals with a reliable and cost-effective solution. By choosing this product, businesses can enhance their welding operations, improve product quality, and achieve greater efficiency in their processes.