CO2 Gas Shielded Copper Plating Micro Wire - HEBEI YUJINHONG

Welding technology has evolved significantly to meet the demands of modern industrial applications. Among the various welding solutions available, CO2 gas shielded copper-plated micro wire stands out as a versatile and efficient option. This article explores the features, advantages, technical specifications, and applications of this advanced welding material, while also highlighting the expertise of its manufacturer, HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Product Overview

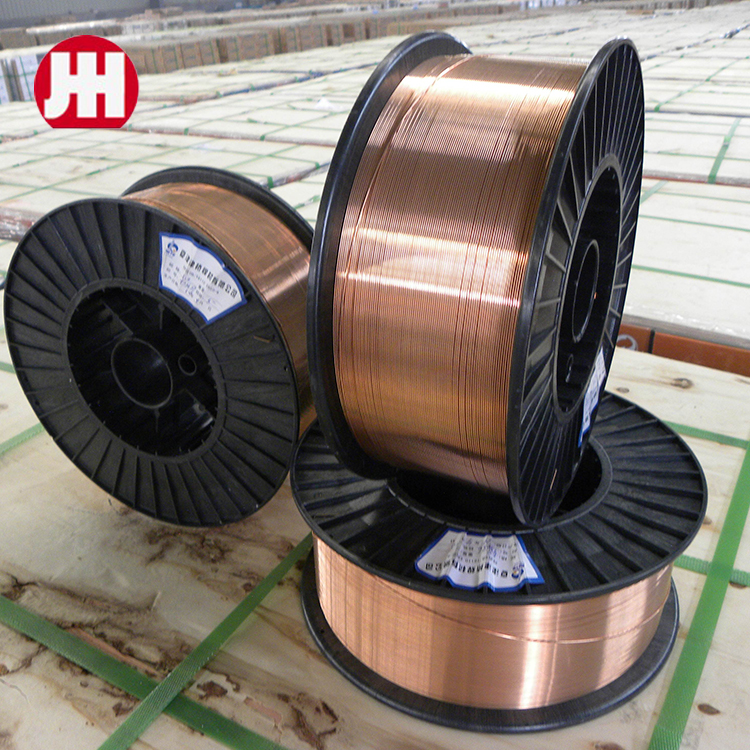

The CO2 gas shielded copper-plated micro wire is a specialized welding consumable designed for carbon steel applications. It utilizes ER70S-6 as its base material, which is a 500MPa-level carbon steel wire. This wire is compatible with CO2 gas or 80% Ar + 20% CO2 gas shielding, making it suitable for a wide range of welding processes. The product is engineered to deliver low spatter, high cladding efficiency, and excellent weld appearance, ensuring superior performance in various industrial settings.

Read More About CO2 Flux Core Welding

Key Features and Advantages

The CO2 gas shielded copper-plated micro wire offers several distinct advantages that make it a preferred choice in the welding industry:

- Low Cost and High Efficiency: The welding process is cost-effective, with reduced power consumption and high production efficiency. This makes it ideal for large-scale manufacturing operations.

- Excellent Welding Performance: The wire ensures stable arc characteristics, minimal spatter, and a beautiful weld appearance. Its low hydrogen and nitrogen content enhances crack resistance, while its low sensitivity to weld metal porosity ensures consistent quality.

- Full-Position Welding Capability: The product supports welding in all positions (PA, PB, PC, PD, PE, PF), providing flexibility for complex joint configurations.

- Corrosion Resistance: The copper plating on the wire's surface not only prevents rust but also improves electrical conductivity and smoothness, reducing the risk of nozzle blockage during welding.

- Minimal Deformation: The welding process results in reduced post-welding deformation, preserving the structural integrity of the workpiece.

Read More About CO2 Gas Shielded Welding Wire

Technical Specifications

| Parameter | Specification |

|---|---|

| Wire Type | ER70S-6 (500MPa Carbon Steel) |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Melting Speed | Fast and consistent |

| Spatter | Low |

| Weld Appearance | Beautiful and uniform |

| Corrosion Resistance | Enhanced by copper plating |

| Welding Positions | PA, PB, PC, PD, PE, PF |

Read More About CO2 Gas Shielded Welding Wire

Applications and Industry Use Cases

The CO2 gas shielded copper-plated micro wire is widely applicable across various industries due to its versatility and performance. Key applications include:

- Automotive Manufacturing: Ideal for welding thin to thick steel plates in vehicle assembly lines.

- Construction and Infrastructure: Suitable for structural steel welding, ensuring durability and strength.

- Heavy Machinery: Used in the fabrication of industrial equipment and machinery components.

- Shipbuilding: Provides reliable welding solutions for marine structures and vessels.

- Energy Sector: Applied in the construction of pipelines, storage tanks, and power generation equipment.

Its ability to handle different plate thicknesses and welding positions makes it a preferred choice for projects requiring precision and efficiency.

Company Background: HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

As a leading manufacturer in the welding consumables industry, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. has established itself as a trusted provider of high-quality welding solutions. The company's commitment to innovation and quality control is evident in its rigorous production processes, which include:

- Raw Material Control: Strict selection and testing of raw materials to ensure consistency and performance.

- Advanced Production Technology: Utilization of state-of-the-art machinery and techniques to produce precision-welding wires.

- Comprehensive Quality Assurance: Rigorous inspection of finished products to meet international standards.

- After-Sales Support: Dedicated customer service to address technical inquiries and provide guidance.

With a focus on sustainability and reliability, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. continues to drive advancements in welding technology, catering to the evolving needs of global industries.

Industry Standards and References

The CO2 gas shielded copper-plated micro wire adheres to international welding standards, ensuring its compatibility with modern welding systems. According to the National Institute of Standards and Technology (NIST), "Gas shielded arc welding processes are critical in achieving high-quality welds with minimal defects. The use of advanced shielding gases and coated electrodes significantly enhances weld integrity and efficiency" (NIST Reference). This aligns with the product's design, which emphasizes low porosity, high oxidation resistance, and stable arc performance.

Conclusion

The CO2 gas shielded copper-plated micro wire represents a significant advancement in welding technology, offering a combination of efficiency, durability, and versatility. Its unique features, such as copper plating for corrosion resistance and low spatter characteristics, make it an ideal choice for a wide range of industrial applications. Manufactured by HEBEI YUJINHONG TECHNOLOGY CO.,LTD., this product exemplifies the company's commitment to innovation and quality.

For more information about the product, visit the official CO2 Gas Shielded Copper Plated Micro Wire page or explore the HEBEI YUJINHONG TECHNOLOGY CO.,LTD. website.

References

NIST Reference: National Institute of Standards and Technology. "Gas Shielded Arc Welding Processes." https://www.nist.gov

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025