Jun . 13, 2024 11:14

Back to list

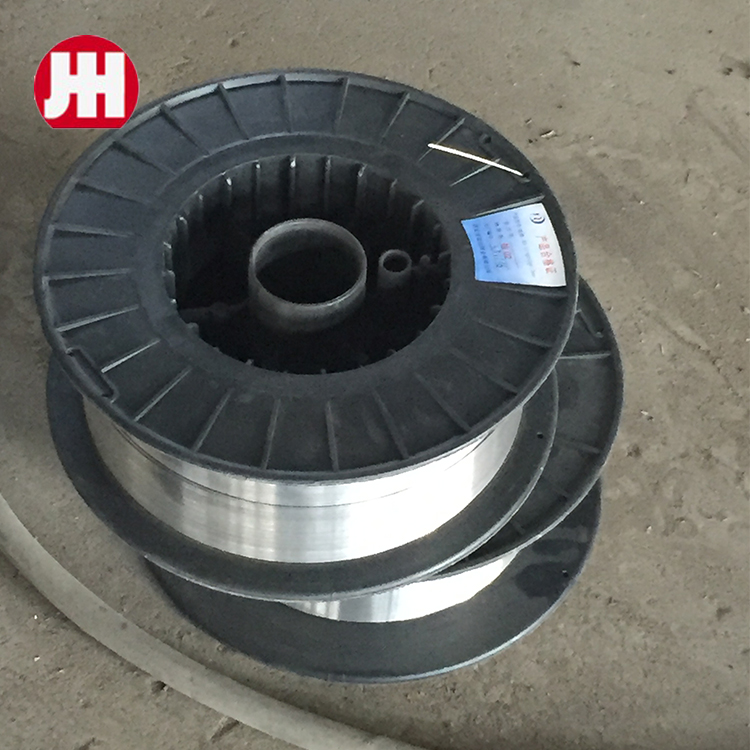

CO2 welding wire manufacturer for Mig welding processes

Understanding Mig Welding with CO2 Wire A Comprehensive Guide on Manufacturers

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding process utilized in various industries due to its efficiency and versatility. A crucial element in this process is the CO2 wire, which serves as the filler material that melts and joins the metal parts together. This article will delve into the intricacies of MIG welding with CO2 wire and highlight some prominent manufacturers in the industry.

CO2 welding, a variant of MIG welding, uses a mixture of carbon dioxide gas as a shielding gas. This gas not only protects the weld pool from atmospheric contamination but also enhances the penetration and weld bead shape. The use of CO2 wire in this process offers several advantages, including higher deposition rates, better weld penetration, and lower costs compared to other shielding gases.

When it comes to CO2 wire manufacturing, quality is paramount. The wire must be made from high-grade materials to ensure consistent performance and durability. Leading manufacturers in this field invest heavily in research and development to produce wires that offer optimal welding characteristics, such as excellent arc stability, minimal spatter, and superior mechanical properties.

One such manufacturer is Lincoln Electric, a global leader in welding technology. Their CO2 wires, designed specifically for MIG welding, are renowned for their consistent quality and performance. They offer a wide range of wires suitable for different materials and applications, ensuring customers can find the perfect match for their welding needs.

Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide mig welding co2 wire manufacturer. Their CO2 wires are engineered to provide excellent weldability, even in demanding conditions. Their commitment to innovation and sustainability sets them apart, making them a preferred choice for many professionals.

In Asia, Hobart Welders is a well-respected name. Their CO2 wires are designed to deliver high deposition rates, low spatter, and deep penetration, making them ideal for heavy-duty applications. Their dedication to customer satisfaction and product reliability has earned them a loyal following.

Lastly, voestalpine Böhler Welding, a European giant, offers a diverse portfolio of CO2 wires, each tailored to specific welding requirements. Their wires are known for their exceptional weldability and resistance to cracking, making them a reliable choice for various industries.

In conclusion, MIG welding with CO2 wire is a powerful technique, and the quality of the wire significantly impacts the welding outcome. Manufacturers like Lincoln Electric, ESAB, Hobart Welders, and voestalpine Böhler Welding play a vital role in providing the industry with top-notch welding consumables. As technology advances, we can expect these companies and others to continue pushing the boundaries of MIG welding with CO2 wire, enhancing efficiency, and delivering superior welding results.

mig welding co2 wire manufacturer. Their CO2 wires are engineered to provide excellent weldability, even in demanding conditions. Their commitment to innovation and sustainability sets them apart, making them a preferred choice for many professionals.

In Asia, Hobart Welders is a well-respected name. Their CO2 wires are designed to deliver high deposition rates, low spatter, and deep penetration, making them ideal for heavy-duty applications. Their dedication to customer satisfaction and product reliability has earned them a loyal following.

Lastly, voestalpine Böhler Welding, a European giant, offers a diverse portfolio of CO2 wires, each tailored to specific welding requirements. Their wires are known for their exceptional weldability and resistance to cracking, making them a reliable choice for various industries.

In conclusion, MIG welding with CO2 wire is a powerful technique, and the quality of the wire significantly impacts the welding outcome. Manufacturers like Lincoln Electric, ESAB, Hobart Welders, and voestalpine Böhler Welding play a vital role in providing the industry with top-notch welding consumables. As technology advances, we can expect these companies and others to continue pushing the boundaries of MIG welding with CO2 wire, enhancing efficiency, and delivering superior welding results.

Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide

Another notable player is ESAB, a Swedish company with a strong presence worldwide mig welding co2 wire manufacturer. Their CO2 wires are engineered to provide excellent weldability, even in demanding conditions. Their commitment to innovation and sustainability sets them apart, making them a preferred choice for many professionals.

In Asia, Hobart Welders is a well-respected name. Their CO2 wires are designed to deliver high deposition rates, low spatter, and deep penetration, making them ideal for heavy-duty applications. Their dedication to customer satisfaction and product reliability has earned them a loyal following.

Lastly, voestalpine Böhler Welding, a European giant, offers a diverse portfolio of CO2 wires, each tailored to specific welding requirements. Their wires are known for their exceptional weldability and resistance to cracking, making them a reliable choice for various industries.

In conclusion, MIG welding with CO2 wire is a powerful technique, and the quality of the wire significantly impacts the welding outcome. Manufacturers like Lincoln Electric, ESAB, Hobart Welders, and voestalpine Böhler Welding play a vital role in providing the industry with top-notch welding consumables. As technology advances, we can expect these companies and others to continue pushing the boundaries of MIG welding with CO2 wire, enhancing efficiency, and delivering superior welding results.

mig welding co2 wire manufacturer. Their CO2 wires are engineered to provide excellent weldability, even in demanding conditions. Their commitment to innovation and sustainability sets them apart, making them a preferred choice for many professionals.

In Asia, Hobart Welders is a well-respected name. Their CO2 wires are designed to deliver high deposition rates, low spatter, and deep penetration, making them ideal for heavy-duty applications. Their dedication to customer satisfaction and product reliability has earned them a loyal following.

Lastly, voestalpine Böhler Welding, a European giant, offers a diverse portfolio of CO2 wires, each tailored to specific welding requirements. Their wires are known for their exceptional weldability and resistance to cracking, making them a reliable choice for various industries.

In conclusion, MIG welding with CO2 wire is a powerful technique, and the quality of the wire significantly impacts the welding outcome. Manufacturers like Lincoln Electric, ESAB, Hobart Welders, and voestalpine Böhler Welding play a vital role in providing the industry with top-notch welding consumables. As technology advances, we can expect these companies and others to continue pushing the boundaries of MIG welding with CO2 wire, enhancing efficiency, and delivering superior welding results. Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025