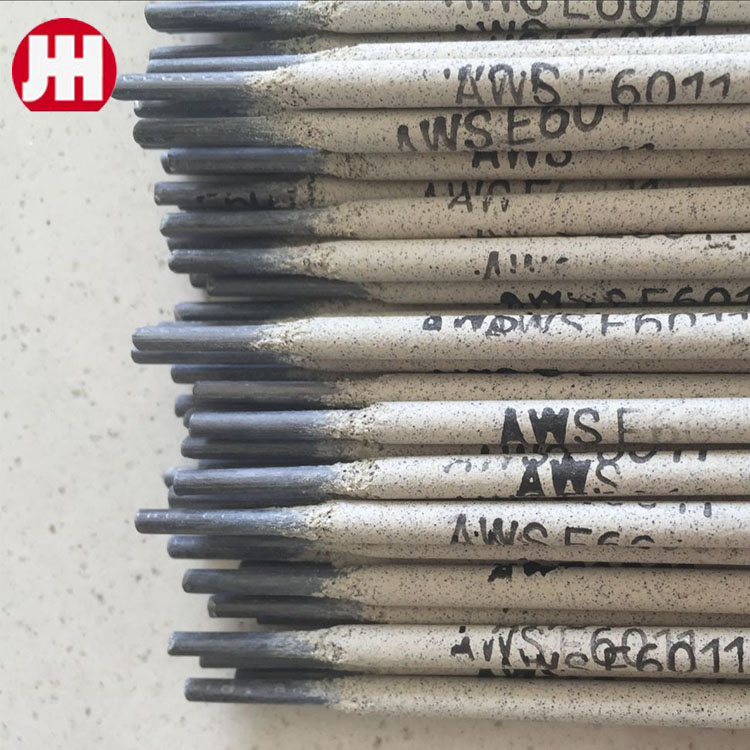

coated electrode welding factory

Exploring the Coated Electrode Welding Factory Innovations and Impact

In the ever-evolving landscape of manufacturing and construction, the coated electrode welding factory has emerged as a cornerstone of modern welding technology. As industries increasingly demand robust and efficient welding solutions, understanding the intricacies of a coated electrode welding factory becomes paramount. This article delves into the workings, innovations, and significance of these specialized facilities.

What is Coated Electrode Welding?

Coated electrode welding, commonly referred to as shielded metal arc welding (SMAW), is a widely used welding process that employs electrodes coated with flux materials. When the electrode is heated during welding, the flux melts, creating a protective gas shield that prevents contamination of the molten weld pool. This method is favored for its versatility, portableness, and the quality of welds produced, making it ideal for various applications, from construction to repairs.

The Function of a Coated Electrode Welding Factory

A coated electrode welding factory specializes in the production of these electrodes. The manufacturing process involves several critical steps

1. Raw Material Selection High-quality steel rods, along with specific flux materials, are essential in producing effective coated electrodes. The choice of materials directly impacts the performance of the electrodes in different welding scenarios.

2. Coating Process The electrode rods are coated with a mixture of flux components, which may include minerals, metal powders, and binding agents. The coating process ensures that the electrodes are consistent in quality and that the flux adheres properly to the rod.

3. Quality Control Rigorous testing is essential to ensure that the electrodes meet industry standards. This includes checks for coating uniformity, adhesion strength, and performance under various welding conditions.

4. Packaging and Distribution Once produced and tested, electrodes are packaged carefully to prevent damage during transportation. Factories often use specialized packaging that preserves the integrity of the products.

coated electrode welding factory

Innovations in Coated Electrode Manufacturing

To keep up with the increasing demands of the industry, coated electrode welding factories are continuously innovating. Recent developments have introduced advanced materials and manufacturing techniques that enhance the performance and durability of electrodes. For instance

- Improved Alloy Formulation New formulations of coating materials have been developed to provide better arc stability, reduced spatter, and improved bead appearance. This not only makes the welding process smoother but also enhances the aesthetic quality of the finished product.

- Automation and Robotics Many factories are integrating automation and robotics into their production lines. This shift not only boosts efficiency but also ensures precise coating applications and minimized errors, ultimately leading to higher quality electrodes.

- Sustainability Efforts As environmental concerns rise, coated electrode production facilities are focusing on greener practices. This includes using recyclable materials for packaging and reducing waste during the manufacturing process.

The Impact of Coated Electrode Welding Factories

The significance of coated electrode welding factories extends beyond production; they play a vital role in supporting various industries. The automotive sector, for instance, relies heavily on high-quality welds for structural integrity and safety. Similarly, the construction industry depends on these electrodes for building strong and durable infrastructures.

Moreover, the economic impact of these factories cannot be overstated. They create jobs, support local economies, and contribute to technological advancements in welding processes. With the global push for infrastructure development, the demand for coated electrodes is set to rise, highlighting the importance of these factories in the economy.

Conclusion

In conclusion, coated electrode welding factories are essential hubs of innovation that significantly impact various industries. Their commitment to quality, safety, and advancements in welding technology makes them indispensable in the welding sector. As we move toward a more industrialized future, the role of these factories will continue to grow, underscoring the importance of understanding and supporting this critical segment of manufacturing. Whether it's for building a skyscraper or repairing machinery, the coated electrode welding factory stands at the forefront of technological progress, driving the industry forward.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025