e6010 welding rod factories

An Overview of E6010 Welding Rod Factories

The E6010 welding rod, known for its versatility and effectiveness, plays a crucial role in various welding applications. These rods are primarily used for the direct current (DC) welding of mild steel, making them a preferred choice for many welding professionals. The manufacturing of E6010 welding rods involves several processes, and numerous factories specialize in their production. In this article, we will explore the key aspects of E6010 welding rod factories.

Manufacturing Process

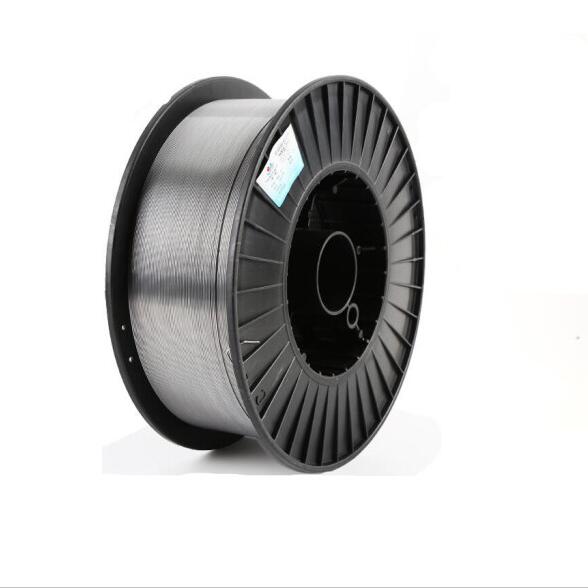

The production of E6010 welding rods begins with the selection of high-quality materials. The core of the rod typically consists of a mild steel wire, while the coating is crucial for the rod's performance. This coating contains various compounds, including cellulose, which contributes to the rod's unique characteristics, such as providing a stable arc and good penetration.

The manufacturing process involves several steps, including wire drawing, coating application, and drying. Initially, steel is drawn into wire form, ensuring it meets the required specifications. Following this, the coating material is applied to the wire. This is often done through a process known as extrusion, where the coating is shaped around the wire. After coating application, the rods are dried and cut to specific lengths, ready for packaging.

Quality Control

Quality control is paramount in E6010 welding rod factories. To ensure that each rod meets industry standards, rigorous testing protocols are implemented throughout the manufacturing process. This includes checking the mechanical properties, such as tensile strength and elongation, as well as ensuring that the chemical composition of the welding rod is consistent.

e6010 welding rod factories

Manufacturers often use advanced technology and equipment to monitor the production process. Automated systems can provide real-time data on the quality of the rods, allowing for immediate adjustments if discrepancies are found. This attention to detail helps ensure that the final product is reliable and performs well during welding applications.

Market Demand

The demand for E6010 welding rods is driven by various industries, including construction, manufacturing, and automotive. Welders favor E6010 rods for vertical and overhead applications due to their ability to produce a stable arc and a smooth finish. This versatility makes them ideal for both novice and experienced welders.

In recent years, the global market for welding rods has seen significant growth, fueled by infrastructure development and increased industrial activities. E6010 welding rods, specifically, are sought after for their reliability and performance, further enhancing their market presence.

Conclusion

E6010 welding rod factories play a critical role in the welding industry, providing essential materials that contribute to the success of countless projects worldwide. Through meticulous manufacturing processes and stringent quality control measures, these factories ensure that every rod meets the high standards required for professional welding applications. As demand continues to rise, the future of E6010 welding rod production looks promising, with advancements in technology and manufacturing processes likely to enhance efficiency and product quality even further.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025