electrodo de soldadura 6013 supplier

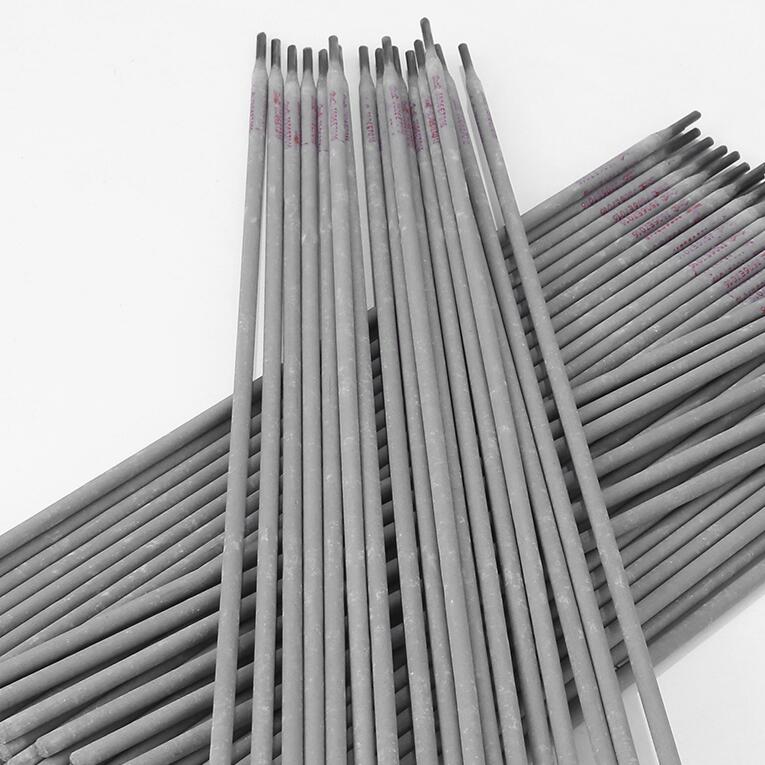

Understanding the 6013 Welding Electrode A Comprehensive Guide for Suppliers

Welding is an essential process in various industries, including construction, automotive, and manufacturing. Among the numerous welding electrodes available in the market, the 6013 welding electrode has gained significant popularity due to its versatility and ease of use. This article aims to provide a detailed overview of the 6013 welding electrode, its characteristics, applications, and the implications for suppliers in the welding industry.

What is the 6013 Welding Electrode?

The 6013 welding electrode is a type of E6013 electrode that utilizes a rutile-coated design. The E denotes that it is an electrode used in arc welding, 60 indicates a minimum tensile strength of 60,000 psi, while 1 signifies the electrode can be used in all positions of welding. The 3 designates the type of coating used, which primarily consists of a mixture of potassium and sodium, imparting notable arc stability and a smooth finish to welds.

Characteristics of 6013 Welding Electrode

1. Versatility One of the most appealing attributes of the 6013 welding electrode is its ability to weld a variety of materials, including mild steel, and light to medium thickness metals. Its adaptability makes it suitable for various applications in both industrial and home environments.

2. Ease of Use The 6013 electrode is user-friendly. It produces a stable arc and provides great puddle control, making it ideal for novice welders and professionals alike. The slag produced during welding is easy to remove, resulting in a clean and aesthetically pleasing weld.

3. Positioning The electrode can be used in all welding positions—flat, horizontal, vertical, and overhead—making it a go-to option for diverse welding projects.

4. Weld Appearance Electrode 6013 is known for producing smooth and visually appealing welds, thanks to its fine slag that contributes to a clean finish.

5. Low Spatter When used correctly, the 6013 electrode generates minimal spatter, further easing cleanup and improving overall productivity.

Applications of the 6013 Welding Electrode

The applications of the 6013 welding electrode are vast. They include

electrodo de soldadura 6013 supplier

- General Fabrication The electrode is commonly used in general fabrication work for structures such as frames, supports, and brackets.

- Automotive Repair It is suitable for automotive welding, making it a preferred choice for repair shops and DIY enthusiasts.

- Manufacturing Industries that require the joining of mild steel and other metal components regularly utilize the 6013 electrode due to its versatility.

- Home Projects The ease of use has made it a popular choice among hobbyists and home improvement aficionados for various DIY projects.

Supplier Considerations for 6013 Welding Electrode

For suppliers, understanding the market demand and trends for the 6013 welding electrode is crucial. Here are several considerations

1. Quality Ensure that the electrodes you offer meet industry standards. Reliability and performance will influence customer satisfaction and repeat business.

2. Packaging Proper packaging is essential to protect electrodes from moisture and damage. Consider offering various packaging options based on customer needs.

3. Education and Support Providing resources such as technical data sheets, safety guidelines, and welding tips can help customers make informed decisions and use the product effectively.

4. Market Trends Stay informed about advancements in welding technology and shifts in customer preferences. This can help in tailoring your product offerings and marketing strategies.

5. Sustainability As industries move towards environmentally friendly practices, suppliers should consider offering eco-friendly welding electrodes or promoting more sustainable practices in the use of welding products.

In conclusion, the 6013 welding electrode is a versatile and user-friendly option for various welding applications. As a supplier, understanding its characteristics and applications can help in effectively marketing the product and meeting the needs of diverse customers. By focusing on quality, education, and sustainability, suppliers can navigate the welding market successfully while providing valuable solutions to their clients.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025