Jan . 20, 2025 04:12

Back to list

ER70S-6 Co2 Solid Mig Welding Wire

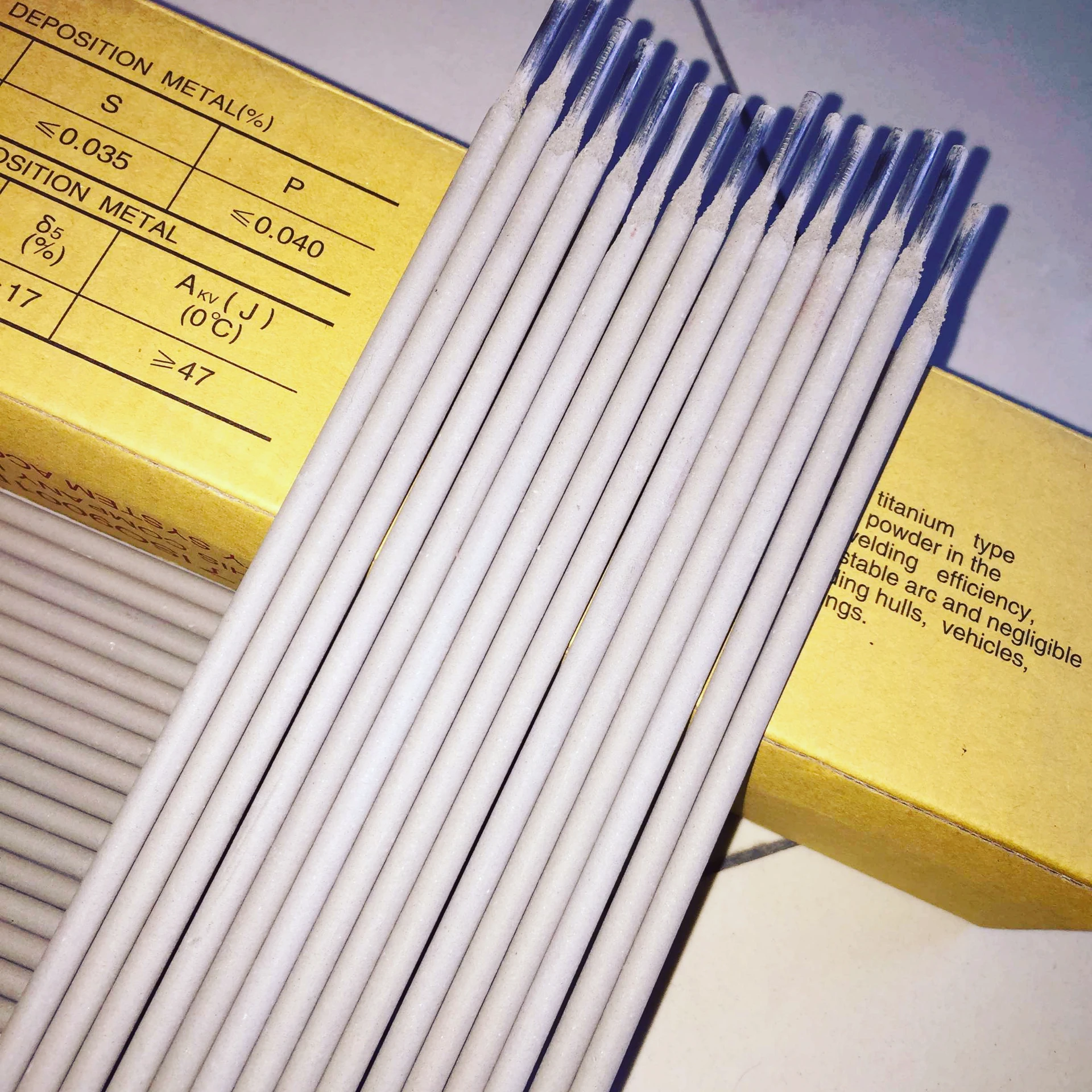

Electrodes 1/8, often referred to in welding and industrial circles, are essential components for various types of welding applications. These electrodes are particularly favored for their versatility, precision, and efficiency. For both novice and expert welders, understanding the nuances of 1/8 electrodes is crucial for optimizing performance and achieving high-quality results.

In terms of professional application, industries such as construction, shipbuilding, and pipeline installation frequently rely on 1/8 electrodes for their projects. The reliability and strength of the welds produced make them indispensable in heavy industry sectors where failure is not an option. Experienced welders in these fields often vouch for the effectiveness and efficiency of 1/8 electrodes, attributing their project's success to the stability and adaptability these electrodes offer. For optimal performance, proper electrode storage and handling are critical. 1/8 electrodes typically require dry storage conditions to prevent moisture absorption, which can lead to hydrogen-induced cracking, particularly in high-strength applications. Ensuring that electrodes are kept at recommended temperatures significantly enhances the reliability of the welds and the safety of the operations. In summary, 1/8 electrodes are a valuable asset for any welding professional seeking precision and quality. Their adaptability across various welding positions and excellent penetration capabilities make them a preferred choice for diverse welding projects. With their proven reliability and performance, they not only meet but often exceed the demands of the most challenging welding applications, thereby solidifying their place as an essential tool in the arsenal of both novice and seasoned welders alike. Choosing the right type of 1/8 electrode, maintaining proper handling practices, and applying expert techniques ensure the high-quality and durability of the welded structures—key factors that contribute to the success of any welding project.

In terms of professional application, industries such as construction, shipbuilding, and pipeline installation frequently rely on 1/8 electrodes for their projects. The reliability and strength of the welds produced make them indispensable in heavy industry sectors where failure is not an option. Experienced welders in these fields often vouch for the effectiveness and efficiency of 1/8 electrodes, attributing their project's success to the stability and adaptability these electrodes offer. For optimal performance, proper electrode storage and handling are critical. 1/8 electrodes typically require dry storage conditions to prevent moisture absorption, which can lead to hydrogen-induced cracking, particularly in high-strength applications. Ensuring that electrodes are kept at recommended temperatures significantly enhances the reliability of the welds and the safety of the operations. In summary, 1/8 electrodes are a valuable asset for any welding professional seeking precision and quality. Their adaptability across various welding positions and excellent penetration capabilities make them a preferred choice for diverse welding projects. With their proven reliability and performance, they not only meet but often exceed the demands of the most challenging welding applications, thereby solidifying their place as an essential tool in the arsenal of both novice and seasoned welders alike. Choosing the right type of 1/8 electrode, maintaining proper handling practices, and applying expert techniques ensure the high-quality and durability of the welded structures—key factors that contribute to the success of any welding project.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025