Electrodos Bridge 6013 3/32 Specifications and Manufacturer Details

Exploring the Electrodos Bridge 6013 3/32 A Manufacturer's Perspective

In the world of welding, selecting the right electrode for a job can significantly influence the quality and integrity of the finished product. One such electrode that has garnered attention in the industrial sector is the Electrodos Bridge 6013 3/32. This particular welding electrode is recognized for its versatility, ease of use, and reliability, making it a preferred choice among welders and manufacturers alike.

The Electrodos Bridge 6013 3/32 is primarily designed for arc welding applications, suitable for a range of metals including mild steel and its alloys. The electrode itself is coated with a special flux, which provides a protective barrier during the welding process. This coating not only helps in stabilizing the arc but also aids in deoxidizing the molten weld pool, allowing for a cleaner and more durable weld.

Product Specifications

The designation 6013 refers to the American Welding Society (AWS) classification of the electrode. The first two digits (60) indicate the minimum yield strength of the weld deposit in thousands of pounds per square inch, while the third digit (1) signifies the electrode's suitability for all positions. The last digit (3) implies a moderate to high level of penetration. The 3/32 measurement denotes the diameter of the electrode, which is essential for ensuring appropriate current settings and achieving optimal weld characteristics.

Benefits of Using Electrodos Bridge 6013 3/32

One of the standout features of the Electrodos Bridge 6013 3/32 is its versatility. Welders can use it for various applications, including structural fabrication, general repairs, and maintenance operations. The electrode performs well on both AC and DC currents, providing welders with flexibility depending on their equipment and preferences.

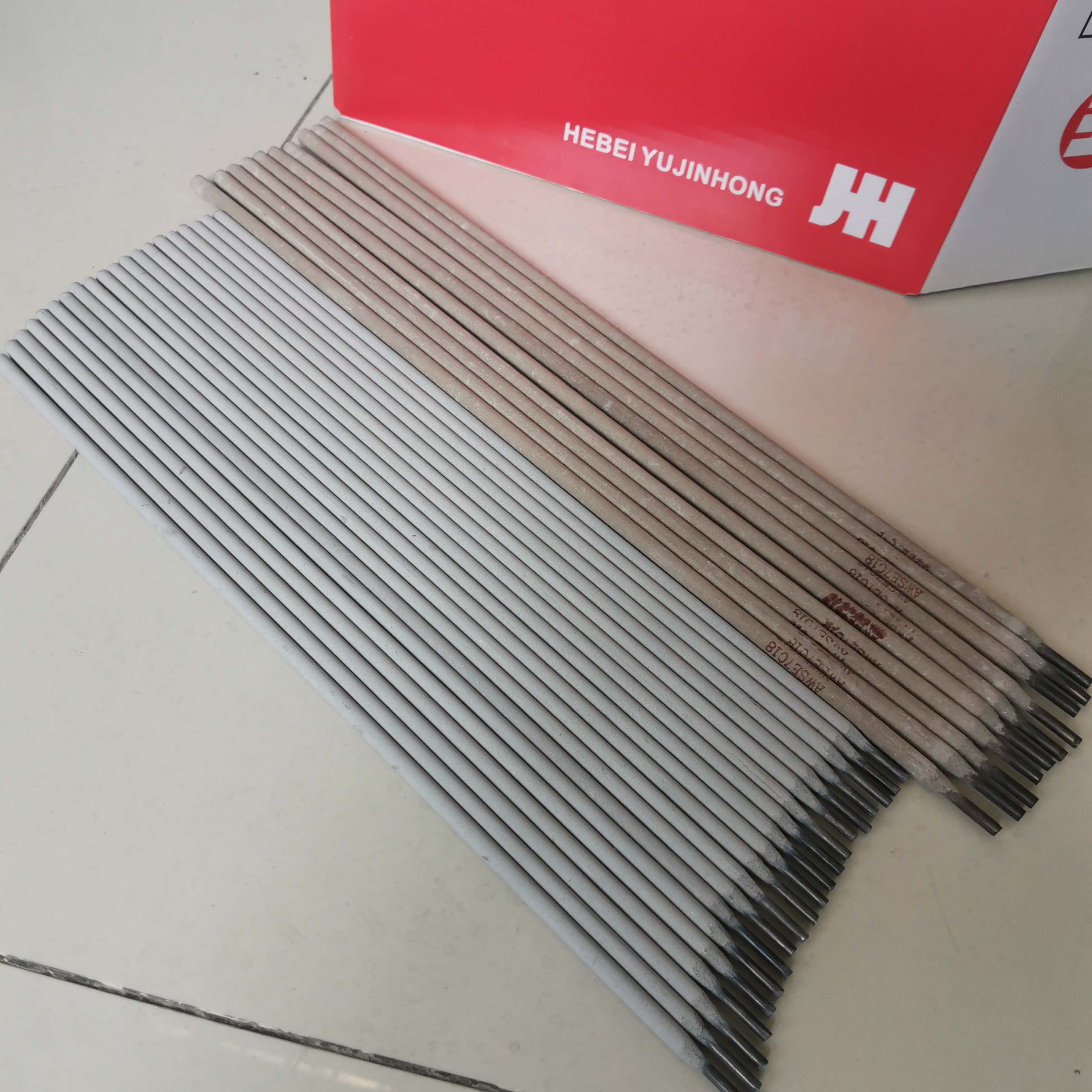

electrodos bridge 6013 3/32 manufacturer

Moreover, the Electrodos 6013 is known for its excellent bead appearance. It produces a smooth finish, reduces spatter, and minimizes the need for extensive cleanup post-welding, which is a significant advantage in both time and cost efficiency. The ease of use of this electrode also makes it suitable for novice welders who may be developing their skills.

Reliability and Quality Assurance

Manufacturers of the Electrodos Bridge 6013 3/32 pride themselves on delivering a product that meets rigorous quality standards. Each batch undergoes stringent testing to ensure consistency in performance and reliability. This commitment to quality is crucial as it directly affects the safety and integrity of welding projects. Anecdotal evidence from users suggests that the Electrodos Bridge 6013 outperforms many competitors in various welding conditions.

Applications Across Industries

The applications of the Electrodos Bridge 6013 3/32 are vast and varied. It is commonly utilized in the construction industry for structural welding, automotive repairs, and even art installations. Its characteristics make it a desirable choice for both heavy-duty and light fabrications. Additionally, the electrode's performance in diverse environmental conditions further enhances its appeal to manufacturers seeking a dependable welding solution.

Conclusion

In conclusion, the Electrodos Bridge 6013 3/32 offers a compelling combination of versatility, reliability, and ease of use, making it a go-to choice for welders across different sectors. With its strong performance in various welding positions and environments, it stands as a testament to the advancements in welding technology and materials. For manufacturers and welders looking for quality and efficiency, the Electrodos Bridge 6013 3/32 electrode undoubtedly represents a valuable investment in their welding arsenal. As the industry continues to evolve, the importance of selecting the right materials will only become more pronounced, and the Electrodos Bridge 6013 3/32 could play a pivotal role in shaping the future of metal fabrication and repair.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025