ER70S-6 Welding Wire Suppliers and Manufacturers for Quality Welding Solutions

The Importance of Selecting the Right ER70S-6 Welding Wire Manufacturer

Welding is a critical process in various industries, from construction to automotive manufacturing. One of the essential materials in welding is the filler wire, where ER70S-6 welding wire has emerged as a popular choice due to its excellent characteristics. When considering the usage of ER70S-6, selecting the right manufacturer can significantly affect the overall quality of the welding job.

Understanding ER70S-6 Welding Wire

ER70S-6 is a type of solid mild steel welding wire widely used in gas metal arc welding (GMAW) and flux-cored arc welding (FCAW). Its designation indicates that it is a wire that is used for welding steel and is suitable for a variety of materials, including those with rust, scale, or dirty surfaces. The ER stands for Electrode Rod, while 70 indicates the minimum tensile strength of 70,000 psi. The S signifies that it is a solid wire, and the 6 refers to its composition, which includes higher levels of deoxidizers like silicon and manganese. These elements improve arc stability and enhance the performance of the wire in various welding conditions.

Quality and Performance

The quality of ER70S-6 welding wire can vary significantly from one manufacturer to another. Choosing a reputable manufacturer is crucial, as the performance of the wire depends highly on its composition and manufacturing process. High-quality welding wire will produce a smoother arc, reduced spatter, and improved mechanical properties in the weld bead. Poor-quality wire, on the other hand, can lead to issues such as porosity, slag inclusions, or undercutting, which can compromise the integrity of the weld and lead to costly rework.

Researching Manufacturers

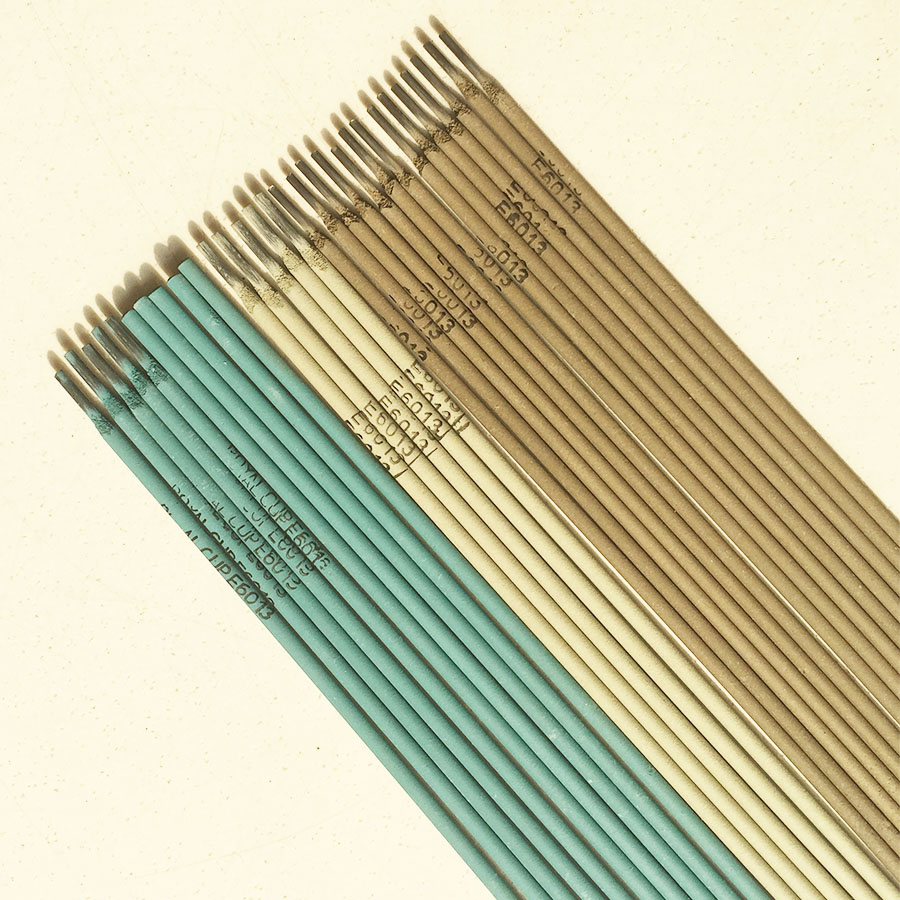

er70s 6 welding wire manufacturer

When looking for an ER70S-6 welding wire manufacturer, it is important to conduct thorough research. Check for ISO certifications, quality control processes, and the manufacturer's reputation in the industry. Reliable manufacturers often provide detailed specifications and certifications for their welding wire, which demonstrates that they adhere to national and international standards. Customer reviews and testimonials can also provide insights into the quality and performance of the welding wire from various manufacturers.

Material Sourcing and Production Standards

A dependable ER70S-6 welding wire manufacturer should source high-quality raw materials for their production. The manufacturing process should comply with stringent quality standards throughout the entire production line. Manufacturers that invest in advanced technology and machinery, along with experienced workforce training, are more likely to produce superior welding wire. Additionally, some manufacturers might offer customized solutions to meet specific project requirements, allowing for greater flexibility in industrial applications.

After-Sales Support and Service

Another crucial aspect of choosing a welding wire manufacturer is the level of after-sales support they provide. A reliable manufacturer should be readily available to address any questions or concerns regarding their product. They should also offer technical support and guidance on the best practices for using the welding wire effectively. Strong customer service can make a significant difference, especially in urgent situations when technical assistance is needed.

Conclusion

In conclusion, selecting the right ER70S-6 welding wire manufacturer is essential for ensuring the quality and reliability of your welding projects. By thoroughly researching manufacturers, considering aspects such as material sourcing, production standards, and after-sales support, you can ensure that you’re using high-quality welding wire that meets your specific needs. This attention to detail can lead not only to superior welds but also to a more successful and efficient welding operation overall. Investing time in choosing the right manufacturer will pay off in the long run, resulting in time-saving and cost-effective welding solutions.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025